Method for assisting in igniting low-volatile coal in burning by adding oxygen

A low-volatility, low-volatility technology, applied in the field of ignition systems, can solve the problems of low volatile matter, oxygen addition ratio, no detailed regulations on the structure, and low volatile matter, so as to speed up the combustion speed and increase the adaptability of coal types , optimize the combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

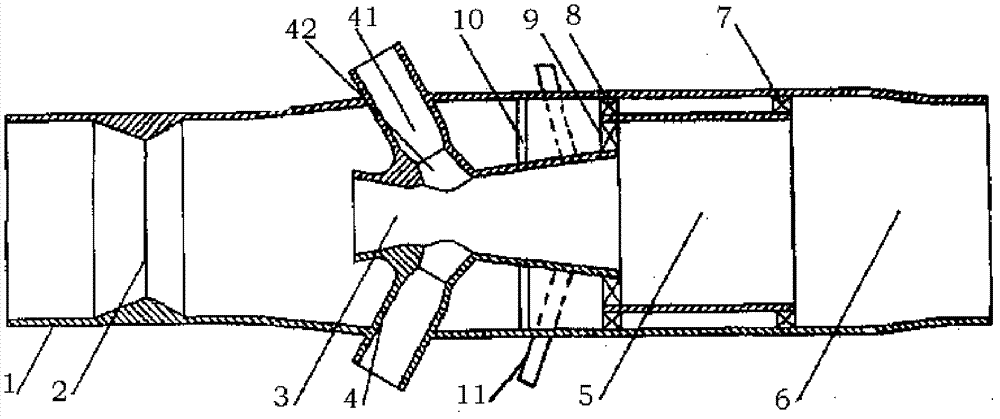

[0012] Low volatile oxygen supplementary micro-oil ignition burner, such as figure 1 As shown, the combustion chamber oxygen supplement micro-oil ignition burner includes four parts: a pulverized coal concentrator, a pulverized coal grading combustion chamber, an oil gun and an oxygen supplement tube. A pulverized coal concentrator 2 with a gradually reduced inner diameter is arranged on the inner wall of the casing 1 near the inlet section (primary air inlet). The back of the pulverized coal concentrator 2 is connected to the three-stage combustion chamber, and the combustion chambers are connected to each other by supporting ribs. The first-stage combustion chamber 3 is connected to the second-stage through the first-level rear rib 9 and the first-level front rib 10 Connection and fixing of the combustion chamber 5, the second-stage combustion chamber is fixed by the second-stage rear rib 7, the second-stage front rib 8 and the first-stage rear rib 9 of the first-stage combust...

Embodiment 2

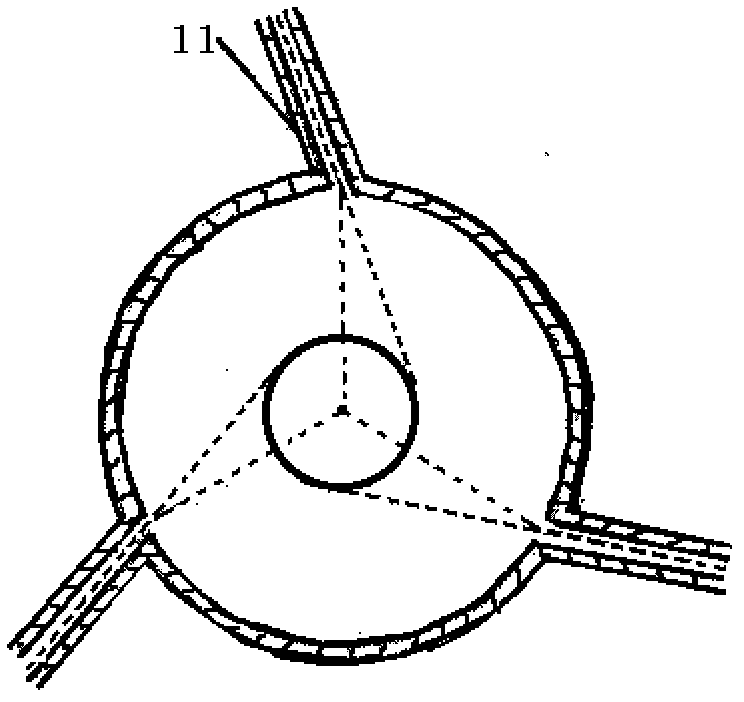

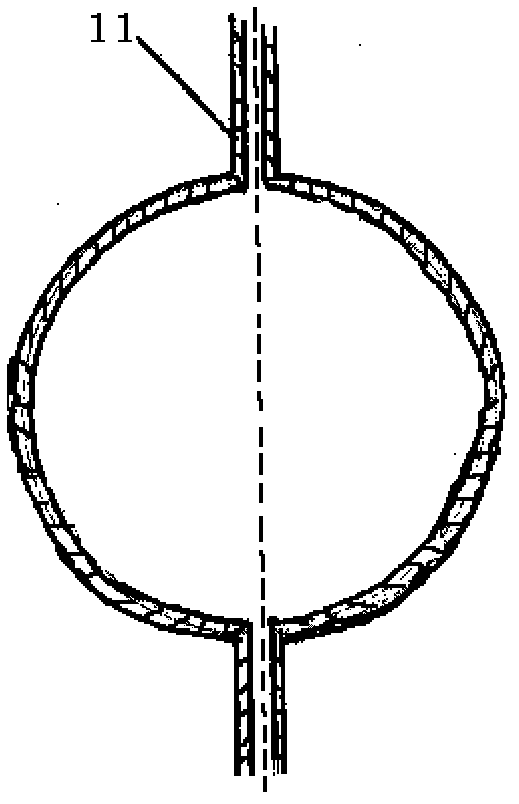

[0014] The difference between Example 2 and Example 1 lies in the way of adding oxygen supplement tube, such as image 3 As shown in the projected cross-sectional schematic diagram of the middle oxygen supplement tube entering the burner inlet, the oxygen supplement tube in Embodiment 2 adopts two oxygen supplement tubes, and the oxygen supplement tube enters the burner in a hedging manner. The two oxygen supplement tubes of Embodiment 2 can also be arranged in a tangential radial direction, and the angle between the axis of the oxygen supplement tube and the normal line of the point is 10-20° in the tangential arrangement. Other aspects are basically the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com