Chemical analysis method for lead elements in tin-lead alloy solder

A tin-lead alloy and solder technology, which is applied in the direction of chemical reaction of materials and material analysis by observing the influence of chemical indicators, can solve the problems of low accuracy of results, improve measurement accuracy and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

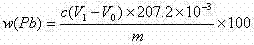

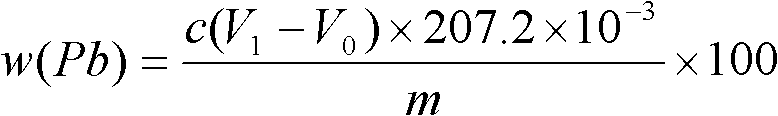

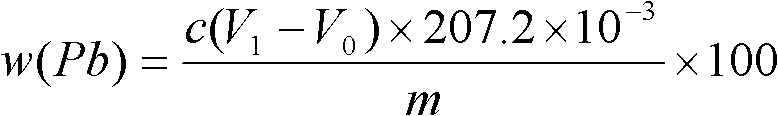

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0021] In this embodiment, the lead element content in a certain brand of tin-lead alloy solder sample is analyzed, and the method comprises the following steps:

[0022] A. Weigh 0.2000g of tin-lead alloy solder sample and place it in a beaker, add 10mL nitric acid into the beaker, place the beaker on a heating plate to heat at 102°C, after white smoke is generated, add 2mL hydrogen peroxide, continue heating until the reaction is over, then add 2mL hydrochloric acid, continue heating until the sample is completely dissolved;

[0023] B. After the beaker is cooled, add 5mL 100g / L potassium sodium tartrate solution, 40mL deionized water and 5mL triethanolamine (1+4) into the beaker, and use hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com