Single-chip ultra-high-voltage constant-current circuit

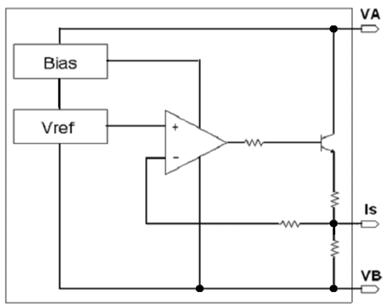

A constant-current circuit, ultra-high voltage technology, applied in the direction of regulating electrical variables, control/regulating systems, instruments, etc., can solve the problems of complex circuit structure, unfavorable production automation, restricted voltage resistance, etc., to achieve simple circuit structure and correct device. The effect of greatly shifting the constant current value and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

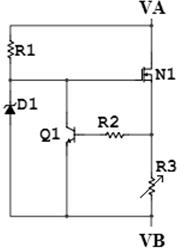

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 2 As shown, the circuit of the present invention includes a high-voltage N-type DMOS transistor N1, a BJT transistor Q1, a high-voltage resistor R1 whose two ends are respectively connected to the grid and drain of the high-voltage N-type DMOS transistor N1, and the two ends are respectively connected to A resistor R2 connected to the source of the high-voltage N-type DMOS transistor N1 and the base of the BJT transistor Q1, and a modifiable resistor R3 whose two ends are respectively connected to the source of the high-voltage N-type DMOS transistor N1 and the emitter of the BJT transistor Q1, And a Zener diode D1 whose cathode is connected to the collector of the BJT transistor Q1, and whose anode is connected to the emitter of the BJT transistor Q1. The gate of the high-voltage N-type DMOS transistor N1 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com