Ionic liquid supported molecular sieve catalyst for synthesizing biodiesel fuel and preparation method of catalyst

A technology of immobilized catalysts and ionic liquids, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as product separation and restrictions on the industrialization of biodiesel , to achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

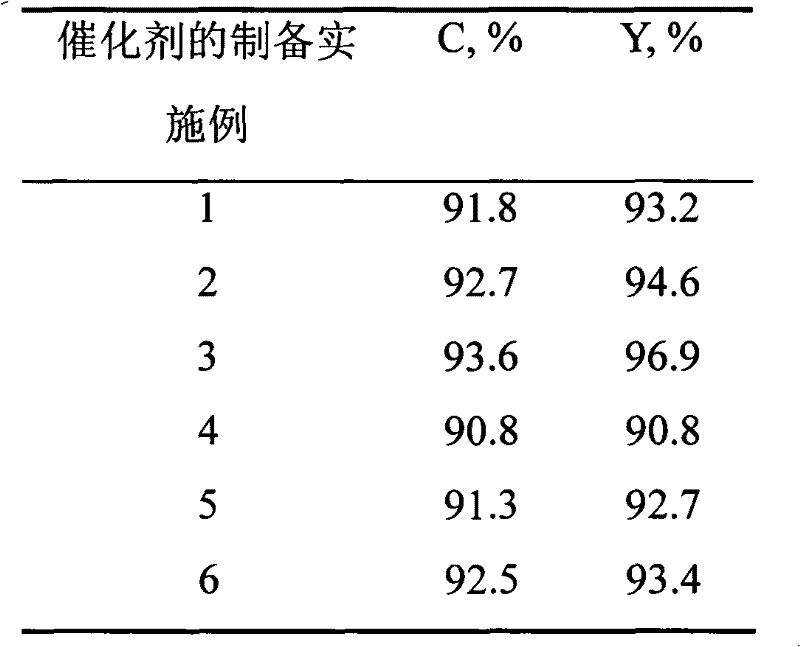

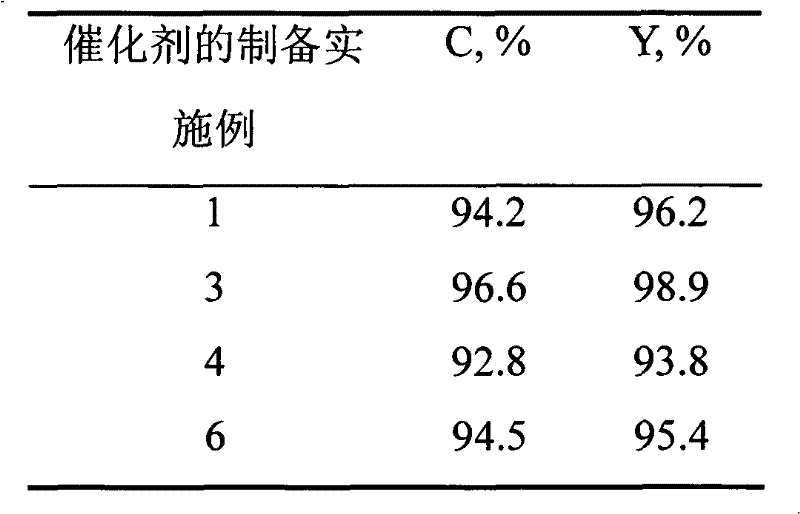

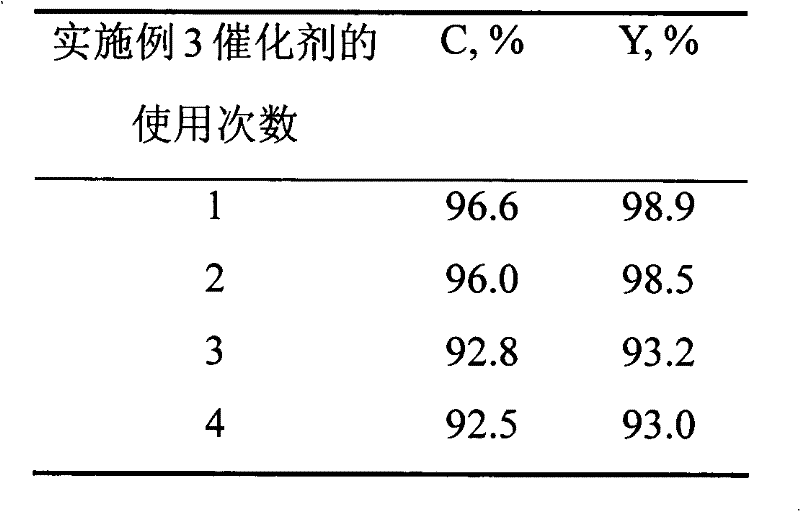

Examples

Embodiment 1

[0018] In the reaction kettle, add 3.85g of dodecylamine, 130ml of water and 32.5ml of absolute ethanol. A mixture of 6.4ml of 3-chloropropyltriethoxysilane, 23ml of ethyl orthosilicate and 50ml of absolute ethanol was placed in the separating funnel. Turn on the power switch of the electric stirrer, set the temperature of the constant temperature water bath to 45°C, add the mixture of 3-chloropropyltriethoxysilane, tetraethyl orthosilicate and ethanol dropwise to the reaction kettle at a constant speed, and stir at constant temperature After 4 hours, the reaction product was aged in a fume hood for 16 hours, and dried by suction filtration. Add 10g of dried raw powder, 67ml of absolute ethanol and 1ml of hydrochloric acid into a 150ml flask, place it in an electromagnetic heating mantle, heat and stir for 4 hours in a boiling state, wash and filter with suction, and repeat this operation three times. Add 10 g of the chloropropyl-functionalized HMS (CP-HMS) obtained in step (...

Embodiment 2

[0020] Under the situation that the preparation conditions of the catalyst are exactly the same as that of Example 1, only the triethylamine (TEA) in the preparation method is changed to tri-n-propylamine (TPA) to obtain 12.0 g of the catalyst.

Embodiment 3

[0022] Under the situation that the preparation conditions of the catalyst are exactly the same as that of Example 1, only the triethylamine (TEA) in the preparation method is changed to tri-n-butylamine (TBA) to obtain 12.5 g of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com