Method for treating contaminated soil by combining in-situ heat strengthening and soil vapor extraction technology

A polluted soil, thermal strengthening technology, applied in the restoration of polluted soil, etc., can solve secondary pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

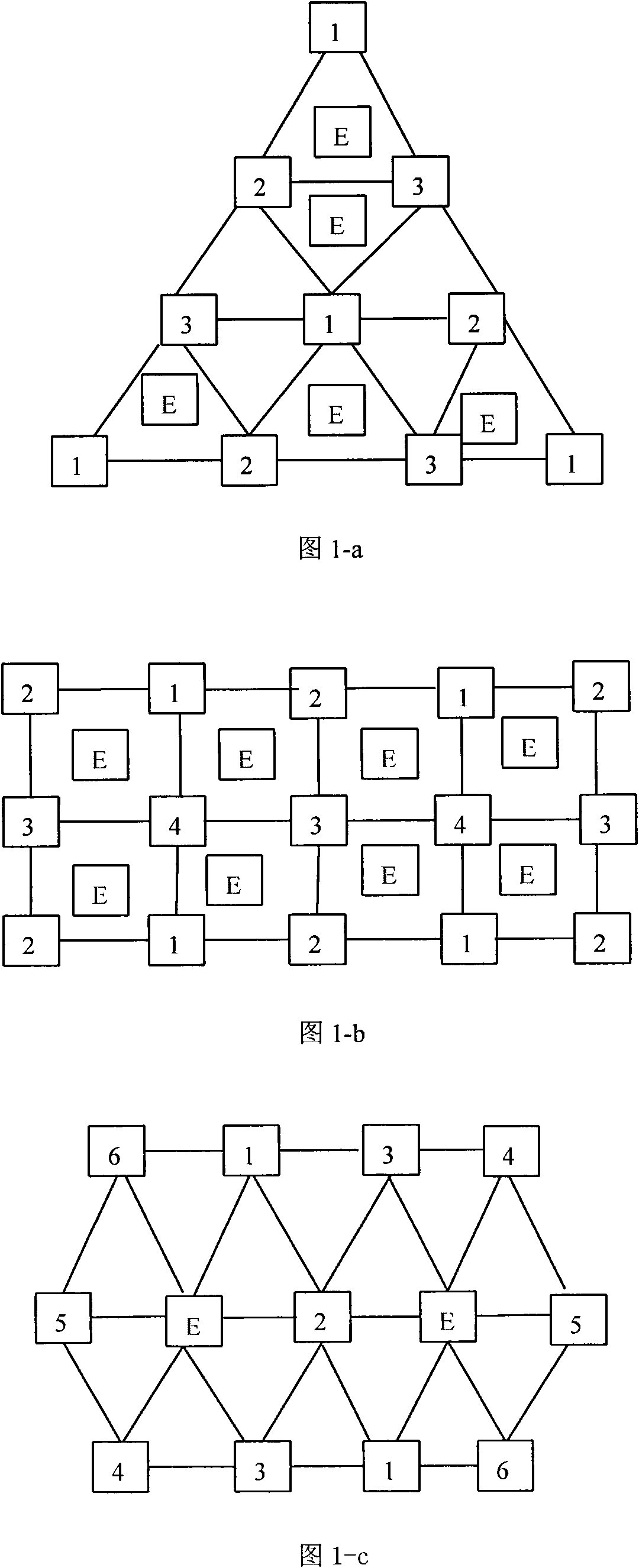

[0023]Figure 1 is a view showing the layout of different forms of heating wells. The heating wells are arranged in a certain form. The form of the layout is conducive to the heater to transfer heat to the adjacent polluted soil in a uniform manner in a long period of time, so as to reduce the removal of pollutants. Repair time required. Specifically, triangles, quadrilaterals, hexamorphs, polygons, etc. can be used, which should cover the entire contaminated area. The interval between heating wells is about 0.9-6 meters, which can be determined according to the specific area of the contaminated area. Fig. 1-a to Fig. 1-c show that the heating wells are arranged in triangular, quadrilateral and hexagonal forms respectively.

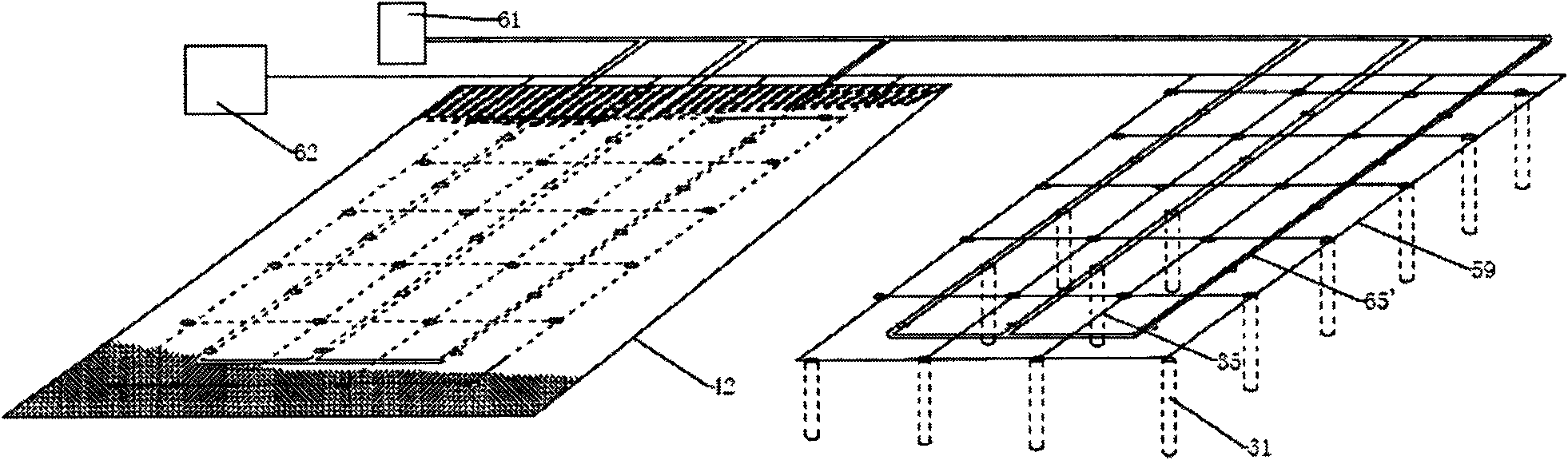

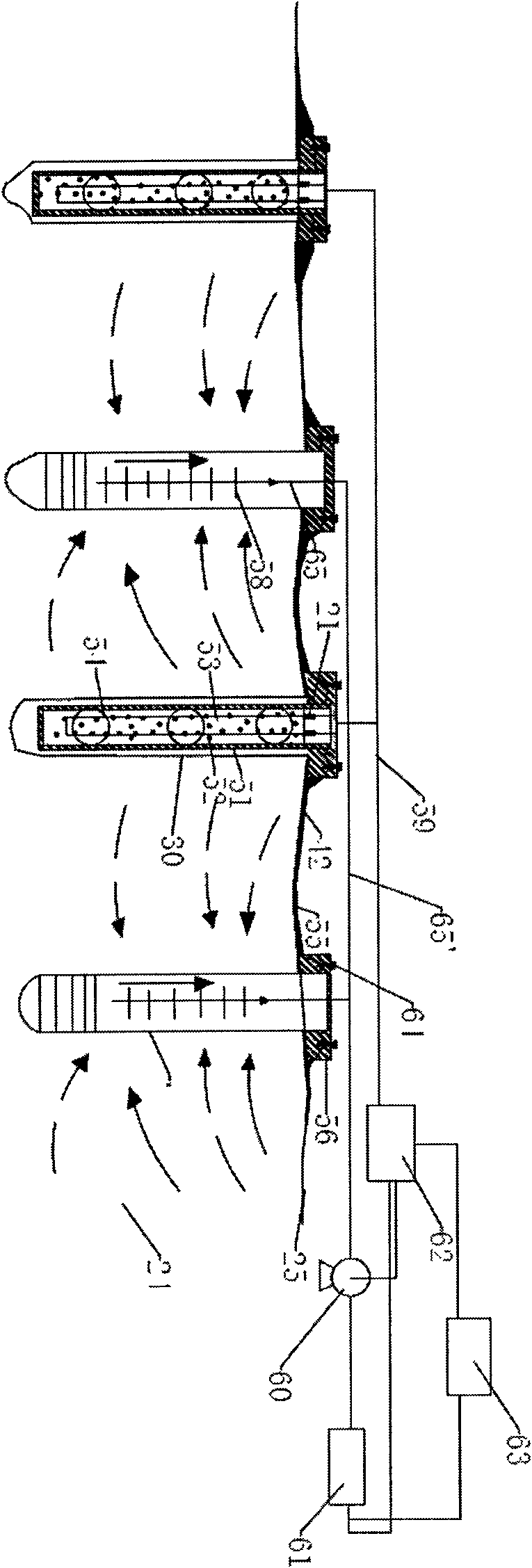

[0024] figure 2 It shows the layout of the heating well and the extraction well and the view of the embodiment of the external connection, in this embodiment, a quadrilateral layout is adopted. The heating wells are connected with each other by conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com