TiO2 powder with visible light catalytic activity and preparation method thereof

A catalytic activity and visible light technology, applied in the field of material science, can solve the problems of low powder purity, poor dispersion, complex equipment and process, etc., and achieve simple process, low preparation cost, good social and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

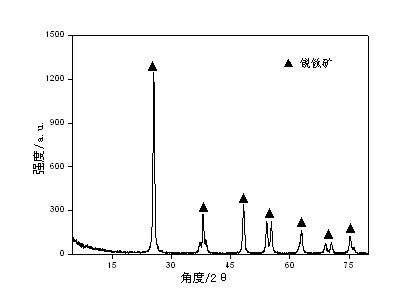

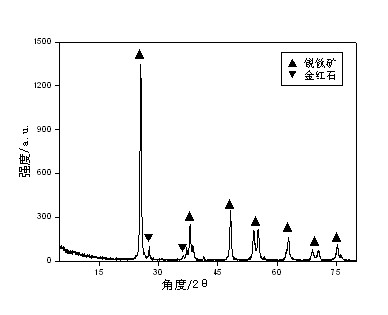

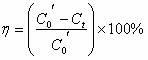

Image

Examples

Embodiment 1

[0032] (1) Preparation of precursor solution A: Add 5ml of tetra-n-butyl titanate dropwise to 20ml of absolute ethanol while stirring, then drop 3ml of glacial acetic acid, after 20 minutes of stirring, a uniform and transparent light yellow solution is obtained, which is the precursor Liquid A;

[0033] (2) Preparation of dripping solution B: A solution of 5ml twice distilled water and 10ml of absolute ethanol, adjust the solution pH=2 with hydrochloric acid, and stir for 20min to obtain dripping solution B;

[0034] (3) Preparation of TiO 2 Wet sol: Add the dropping solution B to the precursor solution A dropwise, and stir in a water bath at a constant temperature of 50℃ for 4 hours to obtain a uniform and transparent light yellow TiO 2 Wet sol, stand for use after 15 hours;

[0035] (4) Preparation of TiO 2 Dry gel: TiO 2 The wet sol is dried in a vacuum drying oven at 60°C for 72 hours to obtain TiO 2 Xerogel

[0036] (5) Preparation of TiO 2 Powder: TiO 2 After the dry gel is gro...

Embodiment 2

[0045] (1) Add 10ml of tetra-n-butyl titanate dropwise to 12ml of absolute ethanol while stirring, then add 7ml of glacial acetic acid, and after 30min of stirring, a uniform and transparent light yellow solution, precursor A, is obtained;

[0046] (2) Preparation of dripping solution B: Mix 10ml of double-distilled water and 8ml of absolute ethanol into a solution, adjust the solution pH=2 with hydrochloric acid, and stir for 20min to obtain dripping solution B;

[0047] (3) Preparation of TiO 2 Wet sol: Add the dropping solution B dropwise to the step precursor A, and stir for 2 hours at a constant temperature of 70°C in a water bath to obtain a uniform and transparent light yellow TiO 2 Wet sol, stand for use after 15 hours;

[0048] (4) Preparation of TiO 2 Dry gel: TiO 2 The wet sol is dried in a vacuum drying oven at 70℃ for 60 hours to obtain TiO 2 Xerogel

[0049] (5) Preparation of TiO 2 Powder: TiO 2 After the dry gel is ground, it is calcined at 500°C under oxidizing atmosph...

Embodiment 3

[0054] (1) Preparation of precursor solution A: Add 15ml of tetra-n-butyl titanate dropwise to 12ml of absolute ethanol while stirring, then drop 3ml of glacial acetic acid, after 50 minutes of stirring, a uniform and transparent light yellow solution is obtained, which is the precursor Liquid A;

[0055] (2) Preparation of dripping solution B: Mix 20ml of double distilled water and 8ml of absolute ethanol into a solution, adjust the pH of the solution to 3 with hydrochloric acid, and stir for 30 minutes to obtain dripping solution B;

[0056] (3) Preparation of TiO 2 Wet sol: Add dropwise solution B to precursor solution A, and stir for 3 hours at a constant temperature of 60℃ in a water bath to obtain uniform and transparent light yellow TiO 2 Wet sol, stand for use after 15 hours;

[0057] (4) Preparation of TiO 2 Dry gel: TiO 2 The wet sol is dried in a vacuum drying oven at 80°C for 24 hours to obtain TiO 2 Xerogel

[0058] (5) Preparation of TiO 2 Powder: TiO 2 After the dry gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com