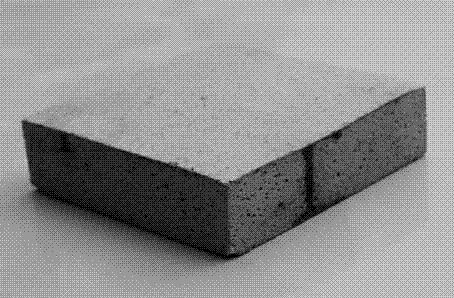

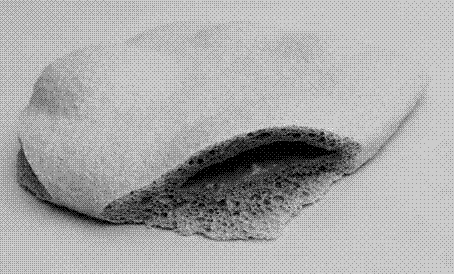

Light environment-friendly brick prepared from waste brick powder, and preparation method for light environment-friendly brick

A technology for environmentally friendly bricks and waste brick powder, which is applied in solid waste management, sustainable waste treatment, climate sustainability, etc., to achieve the effect of solving treatment problems, good economic benefits, and completely uniform internal airtight pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) According to the weight percentage, weigh 50% of the polished brick waste mud, 15% of the waste brick powder, 10% of the air knife soil, 15% of the aluminum ore and 10% of the mung bean mud into the ball mill, and the ball mill is filled with alumina The ball stone is used as the grinding medium, and the ratio of raw materials, grinding medium and water is controlled to be 1:1.8:0.5, and the wet grinding is carried out for 25 minutes. During the wet grinding process, silicon carbide, sodium metasilicate and sodium tripolyphosphate are added. The addition amount is 0.3%, 0.5% and 0.08% of the total mass percentage of the above-mentioned raw materials respectively, and the slurry obtained by wet grinding is passed through a 250-mesh sieve;

[0034] 2) Put the sieved slurry into a constant temperature blast drying oven and dry at 180°C to obtain a powder. The moisture content of the prepared powder is 7.0%-7.5%, and the powder is stale for 1-3 days;

[0035] 3) Put the ...

Embodiment 2

[0039] 1) Pass silicon carbide through a 1000-mesh sieve for later use;

[0040] 2) According to the weight percentage, weigh 60% of the waste polished brick mud, 10% of the waste brick powder, 15% of the air knife soil, 10% of the aluminum ore and 5% of the mung bean mud into the ball mill, and the ball mill is filled with alumina The ball stone is used as the grinding medium, and the ratio of raw materials, grinding medium and water is controlled to be 1:1.8:0.5, and the wet grinding is carried out for 28 minutes. During the wet grinding process, silicon carbide, sodium metasilicate and sodium tripolyphosphate are added. The addition amount is 0.3%, 0.5% and 0.08% of the total mass percentage of the above-mentioned raw materials respectively, and the slurry obtained by wet grinding is passed through a 250-mesh sieve;

[0041] 3) Put the sieved slurry into a constant temperature blast drying oven and dry at 180°C to obtain a powder. The moisture content of the prepared powder...

Embodiment 3

[0046] 1) Pass silicon carbide through a 1000-mesh sieve for later use;

[0047]2) According to the weight percentage, weigh 55% of the polished brick waste mud, 12% of the waste brick powder, 13% of the air knife soil, 13% of the aluminum ore and 7% of the mung bean mud into the ball mill, and the ball mill uses alumina The ball stone is used as the grinding medium, and the ratio of raw materials, grinding medium and water is controlled to be 1:1.8:0.5, and the wet grinding is carried out for 30 minutes. During the wet grinding process, silicon carbide, sodium humate and sodium tripolyphosphate are added. The addition of these three substances The amount is respectively 0.3%, 0.5% and 0.08% of the total mass percentage of the above-mentioned raw materials, and the slurry obtained by wet grinding is passed through a 250-mesh sieve;

[0048] 2) Put the sieved slurry into a constant temperature blast drying oven and dry at 180°C to obtain a powder. The moisture content of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com