Environment friendly blast furnace stemming

An environment-friendly blast clay technology, applied in the field of refractory materials, can solve the problems of poor adaptability, large quality fluctuation, and high consumption of blast clay, and achieve the effects of low labor intensity, strong slag resistance, and low iron consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

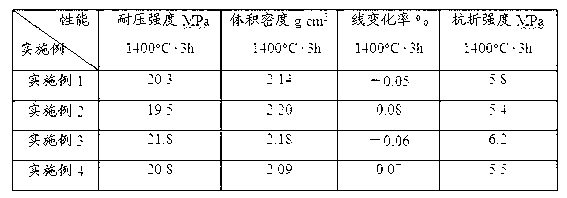

Examples

Embodiment 1

[0022] for 3200m 3 Blast furnace clay, the parts by weight of its components are as follows: corundum: 5 parts, alumina powder: 20 parts, silicon carbide: 20 parts, composite clay: 20 parts, composite powder: 25 parts, rutile powder: 3 parts , ferrosilicon nitride: 6.8 parts, wetting agent: 0.2 parts; modified asphalt obtained after fractionation: 13 parts; wherein the composite powder is a mixture of silicon oxide and boron carbide with a weight ratio of 1:2, and the composite clay is A mixture of equal weights of kaolin and ball clay. The above-mentioned gun mud adopts the following method to prepare: in the mud rolling machine, 65 o After rolling for 30 minutes, the block will be cut into slices, and then the sliced material will be added to the extruder to be extruded into strips for output.

Embodiment 2

[0024] for 4700m 3 Blast furnace clay, the parts by weight of its components are as follows: corundum: 20 parts, homogenized bauxite: 10 parts, silicon carbide: 15 parts, composite clay: 15 parts, composite powder: 19.5 parts, rutile powder: 5 parts, ferrosilicon nitride: 15 parts, wetting agent: 0.5 parts; modified binder added with 5~10% of total weight of sodium peroxide: 20 parts; the weight ratio of composite powder is 1:1:6 It is a mixture of titanium oxide, aluminum oxide and boron carbide, and the composite clay is a mixture of kaolin, ball clay and bentonite in equal weight. The above-mentioned gun mud adopts the following method to prepare: in the mud rolling machine 75 o After rolling for 30 minutes, the block will be cut into slices, and then the sliced material will be added to the extruder to be extruded into strips for output.

Embodiment 3

[0026] for 2500m 3 Blast furnace clay, the parts by weight of its components are as follows: corundum: 12 parts, alumina powder: 30 parts, silicon carbide: 15 parts, composite clay: 10 parts, composite powder: 18 parts, rutile powder: 1 part , ferrosilicon nitride: 13.5 parts, wetting agent: 0.5 parts; modified binder: 17 parts; wherein the composite powder is a mixture of magnesium oxide, calcium oxide and silicon carbide in a weight ratio of 1:1:5. The above-mentioned gun mud adopts the following method to prepare: in the mud rolling machine 70 o After rolling for 35 minutes, the block will be cut into slices, and then the sliced material will be added to the extruder and extruded into strips for output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com