Preparation method of waste plastic composite material modified by waste circuit board non-metal powder

A waste circuit board and non-metallic powder technology, which is applied in the field of preparation of waste circuit board non-metal powder modified waste plastic composite materials, can solve the problems of environmental pollution, waste of useful resources, etc., to improve overall performance, ease processing pressure, Effect of improving interfacial bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

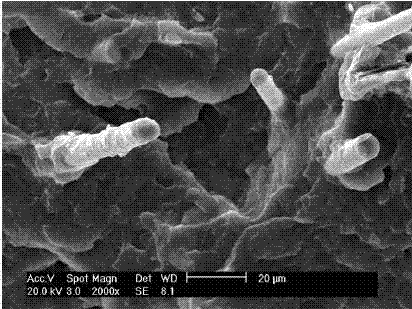

Image

Examples

Embodiment 1

[0017] Example 1: Using water as the liquefaction solution and sulfuric acid as a catalyst, the non-metallic powder of the waste circuit board is activated by hydrothermal method to obtain the non-metallic powder of the waste circuit board activated by the hydrothermal method; The non-metallic powder of the waste circuit board and the reclaimed waste polyethylene are mixed and extruded in a parallel co-rotating twin-screw extruder to obtain a modified waste plastic composite material filled with the non-metal powder of the waste circuit board.

[0018] Step (1): Add 800mL of water and 80mL, 90% weight concentration sulfuric acid solution in the autoclave, stir with a glass rod for 10 minutes, then add 250g of dry waste circuit board non-metallic powder, stir and disperse with a glass rod for 30 Minutes later, treated at 180°C for 4 hours, diluted and washed with deionized water, filtered by filter membrane, washed repeatedly until the filtrate was neutral, and dried at 120°C fo...

Embodiment 2

[0023] Embodiment 2: Using water as the liquefaction solution and potassium hydroxide as the catalyst, the non-metallic powder of the waste circuit board is activated by hydrothermal method to obtain the non-metallic powder of the waste circuit board activated by the hydrothermal method; The activated waste circuit board non-metal powder and waste polypropylene reclaimed material are mixed and then extruded in a parallel co-rotating twin-screw extruder to obtain a waste circuit board non-metal powder filled modified waste plastic composite material.

[0024] Step (1): Add 900mL of water and 90g of potassium hydroxide into the autoclave, stir with a glass rod for 20 minutes, then add 300g of dry waste circuit board non-metallic powder, stir and disperse with a glass rod for 20 minutes, After treatment at 160°C for 6 hours, dilute and wash with deionized water, filter with filter membrane, wash repeatedly until the filtrate is neutral, and dry at 100°C for 6 hours to obtain non-m...

Embodiment 3

[0028] Example 3: Using water as the liquefaction solution and potassium carbonate as a catalyst, the non-metallic powder of the waste circuit board is activated by hydrothermal method to obtain the non-metallic powder of the waste circuit board activated by the hydrothermal method; then the above is activated by the hydrothermal method The waste circuit board non-metal powder and the waste polyvinyl chloride recycled material are mixed and then extruded in a parallel co-rotating twin-screw extruder to obtain a waste circuit board non-metal powder filled modified waste plastic composite material.

[0029] Step (1): Add 600mL of water and 60g of potassium carbonate in the autoclave, stir with a glass rod for 20 minutes, then add 200g of dry waste circuit board non-metallic powder, stir and disperse with a glass rod for 30 minutes, After being treated at 170°C for 5 hours, it was diluted and washed with deionized water, filtered by filter membrane, washed repeatedly until the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com