Dealcoholized one-component room temperature vulcanized silicone rubber and preparation method thereof

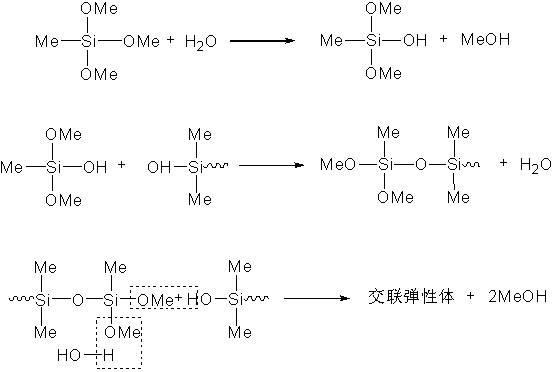

A room temperature vulcanization and dealcoholization technology, applied in the field of room temperature vulcanization silicone rubber, can solve the problems of affecting production efficiency, performance degradation, slow curing speed, etc., and achieve the effects of improving storage stability, accelerating curing speed, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

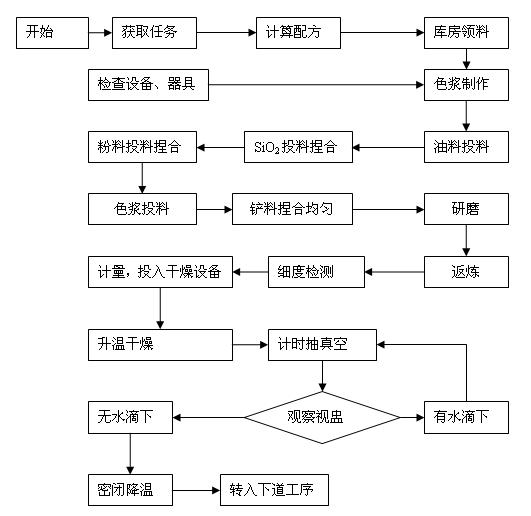

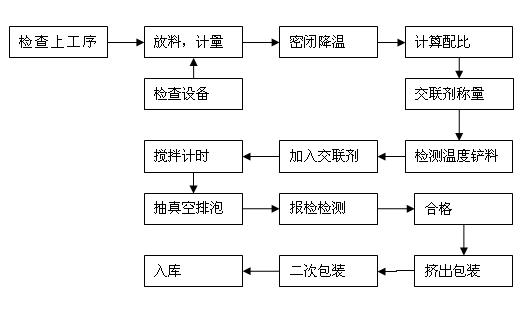

[0037] Weigh 90 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 500mpa.s, 1 part of linear polydimethylsiloxane with a hydroxyl group and a viscosity of 5mpa.s, 5 parts of white carbon black, organic titanium 1 part of acid ester chelate, 4 parts of methyltrimethoxysilane; α, ω-dihydroxypolydimethylsiloxane, linear polydimethylsiloxane with hydroxyl terminal group and white carbon black Mix evenly in the kneader, then transfer to the three-roll machine for grinding, and then transfer to the kneader to heat up and stir to form rubber, then keep the temperature of the rubber at 100 ℃ and the vacuum degree of 0.085 Mpa, stir and vacuumize Dry for 2 hours, airtight for use;

[0038] Put the dried rubber into the planetary stirring tank, when the airtight temperature of the rubber is within 50 ℃, add organic titanate chelate and methyl trimethoxysilane, stir at high speed for 20 minutes, then vacuumize and stir for 10 minutes , and then the vacuum is eliminated to ...

Embodiment 2

[0040] Weigh 105 parts of 5000mpa.sα, ω-dihydroxypolydimethylsiloxane, 5 parts of 50mpa.s linear polydimethylsiloxane with hydroxyl end groups, 10 parts of white carbon black, organic titanate chelate 2 parts of compound, 7 parts of methyltrimethoxysilane;

[0041] Mix α,ω-dihydroxypolydimethylsiloxane, linear polydimethylsiloxane with hydroxyl end groups and white carbon black in a kneader, and then transfer to a three-roll machine for grinding. After uniformity, transfer to a kneader to heat up and stir to form a rubber material, then keep the temperature of the rubber material at 125°C and the vacuum degree of 0.095 Mpa, stir and vacuum dry for 3 hours, and seal it for use.

[0042] Put the dried rubber into the planetary stirring tank, when the airtight temperature of the rubber is within 75°C, add organic titanate chelate and methyl trimethoxysilane, stir at high speed for 30 minutes, then vacuumize and stir for 20 minutes , and then the vacuum is eliminated to obtain de...

Embodiment 3

[0044] Weigh 120 parts of 10000mpa.sα, ω-dihydroxypolydimethylsiloxane, 10 parts of 100mpa.s linear polydimethylsiloxane with hydroxyl end groups, 15 parts of white carbon black, organic titanate chelate 3 parts of compound, 10 parts of methyltrimethoxysilane;

[0045] Mix α,ω-dihydroxypolydimethylsiloxane, linear polydimethylsiloxane with hydroxyl end groups and white carbon black in a kneader, and then transfer to a three-roll machine for grinding. After uniformity, transfer to a kneader to heat up and stir to form a rubber compound, then keep the temperature of the rubber compound at 150 ° C and a vacuum degree of 0.105 Mpa, stir and vacuum-dry for 4 hours, and seal it for use.

[0046] Put the dried rubber material into the planetary stirring tank, when the sealing temperature of the rubber material is within 100 ℃, add organic titanate chelate and methyl trimethoxysilane, stir at high speed for 40 minutes, and then vacuumize and stir for 30 minutes , and then the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com