Slurry stabilizing agent and applications thereof

A slurry stabilizer and stabilization technology, applied in the field of slurry stability and application, can solve the problems of limited effect of slurry stability, high viscosity and high energy consumption, achieve high popularization and application value, improve stability, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

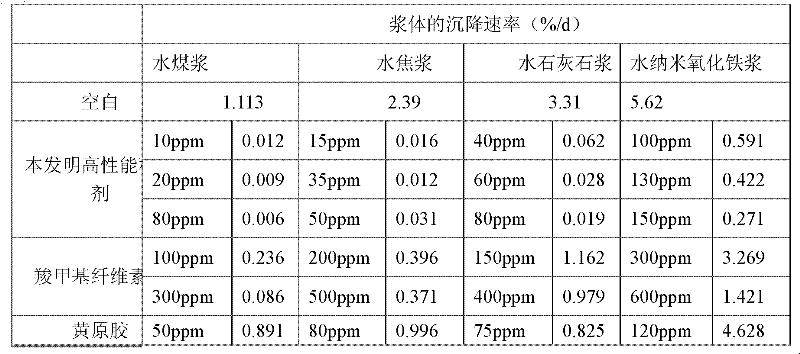

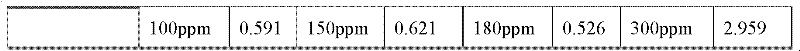

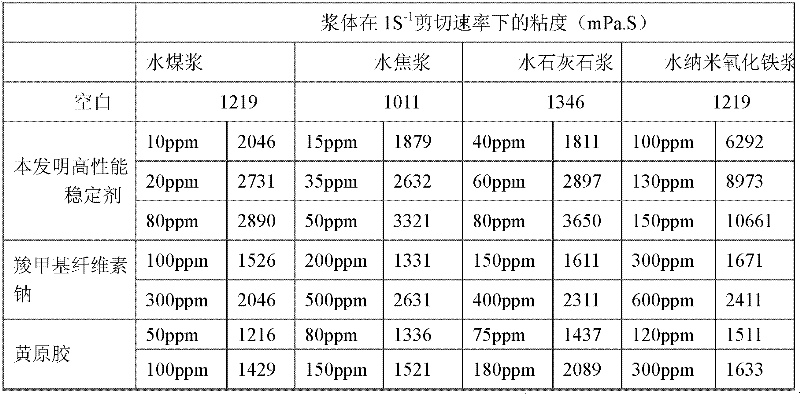

Examples

Embodiment 1

[0010] In 1000g of Datong coal water slurry with a concentration of 64% (the average particle size of coal particles is 42.0μm), add 1g of 1% stabilizer solution (molecular weight is 200,000, maleic acid grafting rate is 12%, acrylic acid The grafting rate of the ester is 1%, the molecular weight is 2000, and the dosage is 10 ppm), the slurry is prepared by stirring for 5 minutes, the rheological properties are measured, and the static stability is observed by standing.

Embodiment 2

[0012] In 1000g of Datong coal-water slurry with a concentration of 64% (the average particle size of coal particles is 42.0μm), add 2g of 1% stabilizer solution (molecular weight is 200,000, maleic acid grafting rate is 12%, acrylic acid The grafting rate of the ester is 1%, the molecular weight is 2000, and the dosage is 20 ppm), the slurry is prepared by stirring for 5 minutes, the rheological properties are measured, and the static stability is observed by standing.

Embodiment 3

[0014] In 1000g of Datong coal water slurry with a concentration of 64% (the average particle size of coal particles is 42.0μm), add 8g of 1% stabilizer solution (molecular weight 65000, maleic acid grafting rate 12%, acrylic acid The grafting rate of the ester is 1%, the dosage is 80ppm), the slurry is prepared by stirring for 5 minutes, the rheological properties of the slurry are measured, and the static stability is observed by standing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com