Refractory steel for vane of steam turbine of ultra supercritical fossil power plant and manufacturing method

A technology for steam turbine blades and thermal power units, which is applied in the field of heat-resistant steel and manufacturing, can solve problems such as failure to meet performance requirements, and achieve the effects of high steam corrosion resistance and high creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

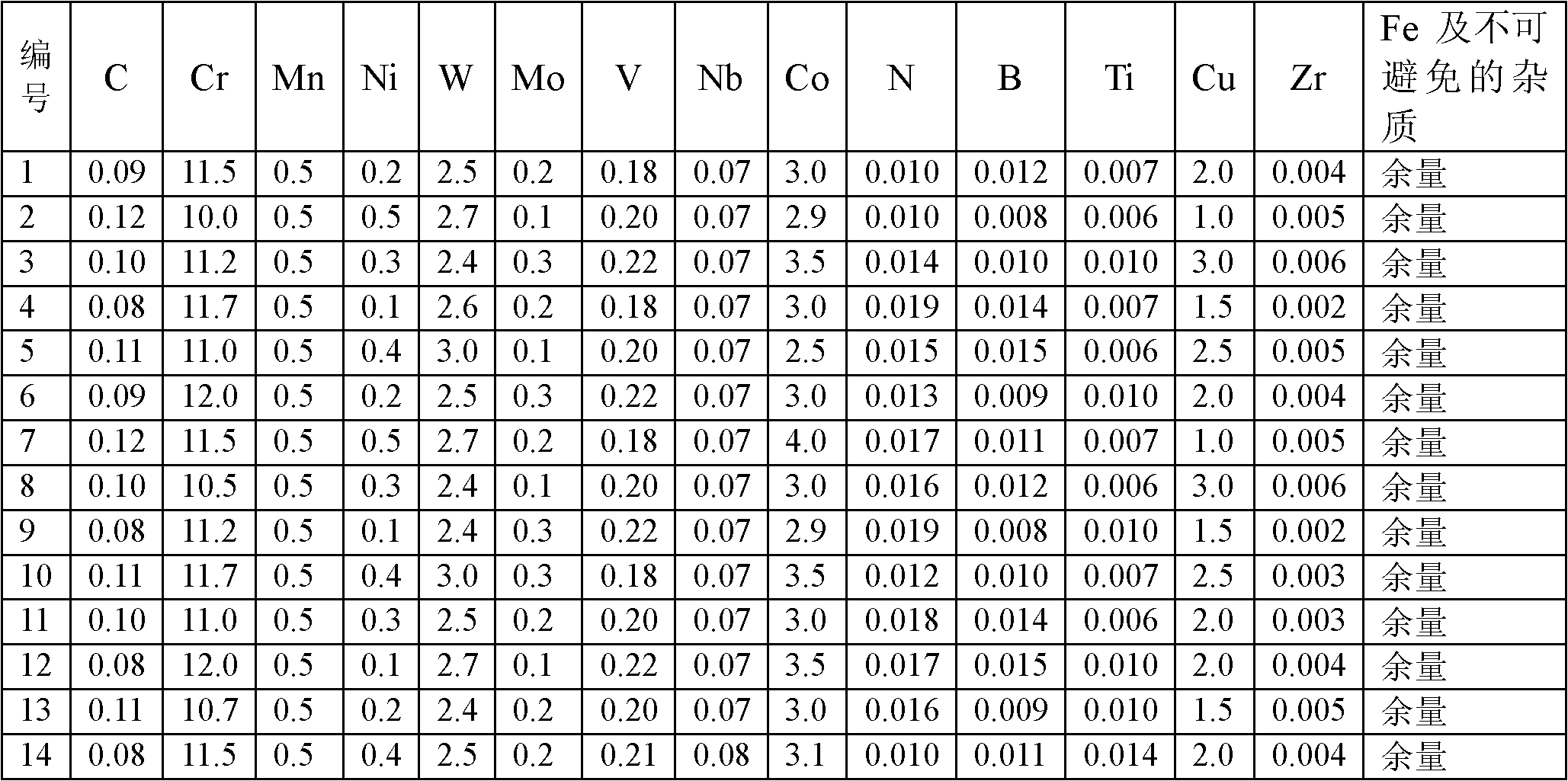

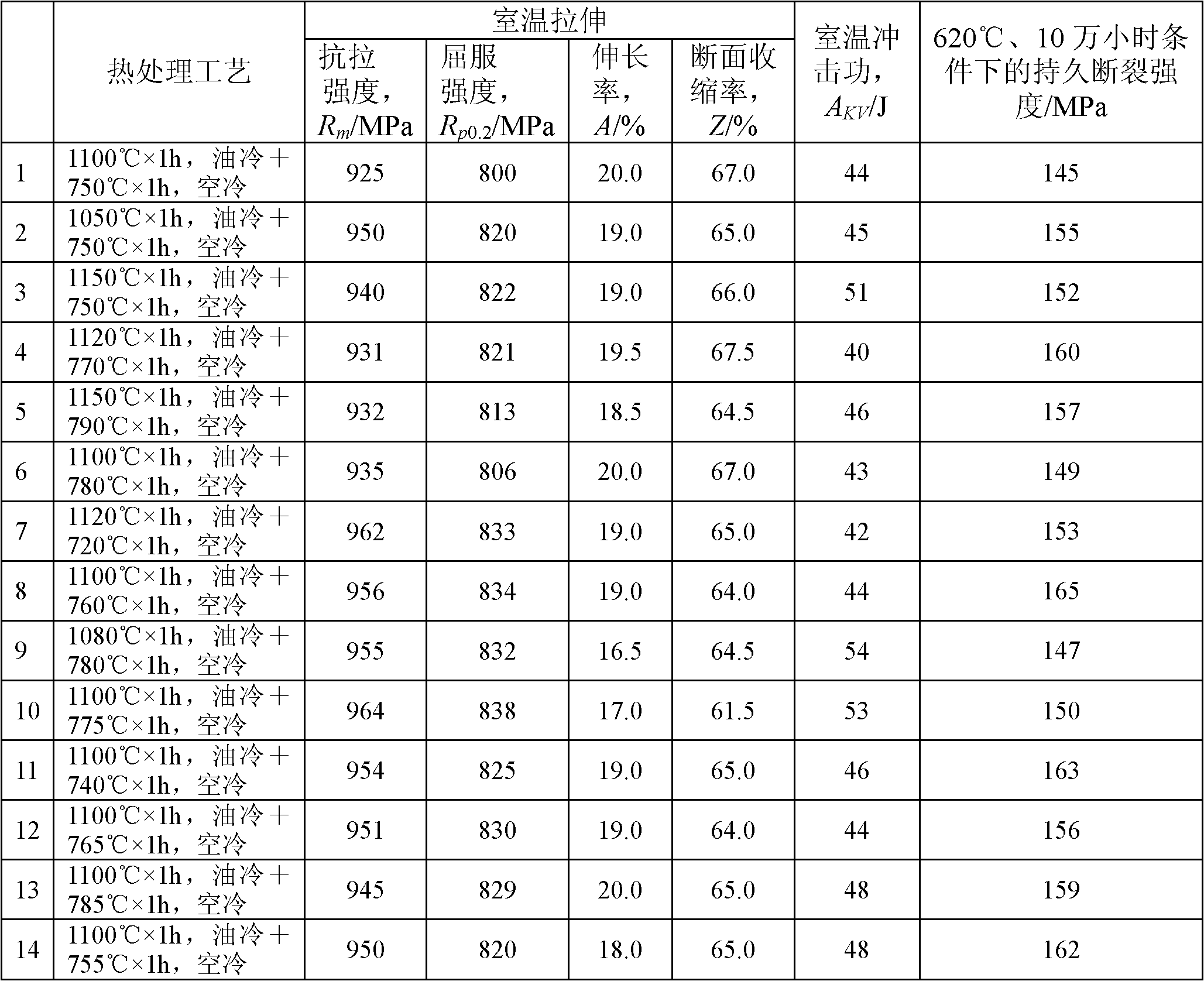

[0025] Table 1 lists 14 kinds of heat-resistant steels whose composition is within the specified composition range of the present invention. The production methods are as follows: use a vacuum induction furnace to sequentially melt and pour the raw material composition of the constituent elements to obtain a heat-resistant steel ingot, and then forge the heat-resistant steel ingot to obtain a φ20mm bar. Heat treatment process After heat treatment, it is processed into standard tensile creep specimens and Charpy V-notch impact specimens, and then tensile and impact tests at room temperature and durable fracture tests at 600-700°C are performed. According to the results of the durable test , using the Larson-Miller parameter method to estimate the durable fracture strength at 620°C and 100,000 hours. The test results are shown in Table 2. It can be seen from Table 2 that the heat-resistant steel of the present invention has good strength and toughness and obviously high high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com