Method for preparing inorganic fireproof plate for building by adopting steel slag tailings and desulfurized gypsum

An inorganic fireproof board, desulfurization gypsum technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of slow hydration speed, low strength, limited excitation effect, etc. Low calorific value and the effect of improving gelling activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

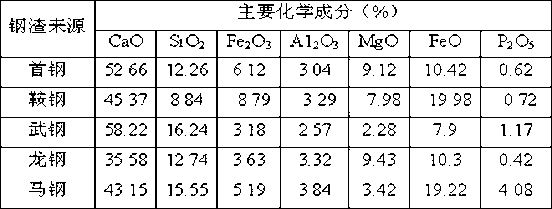

[0022] 1. Sieve the steel slag tailings (chemical composition shown in Table 1) of Shougang, and select particles with a particle size of 40-100 mesh for fine grinding to achieve a specific surface area of 3800cm 2 / g. The specific surface area is 2500cm 2 / g desulfurized gypsum is heat-treated at 180°C for 2 hours, and all raw materials are mixed according to the following parts by weight:

[0023] Steel slag tailings 60 parts

[0024] 40 parts of desulfurized gypsum

[0025] Whisker plaster 2 parts

[0026] Water glass 0.1 part

[0027] Quicklime 2 parts

[0028] 2 parts alum

[0029] 2. After mixing and stirring the above raw materials for 30 minutes, add water according to the mass ratio of raw materials and water of 1:0.50, mix and stir for 120 s, pour into the mold for 24 hours, demold and cure for 3 days.

[0030] 3. The compressive strength of the 20×20×20mm block reaches 9.83MPa, and the bulk density is 442 kg / m 3 , to meet the national standard GB8624-2006 ...

Embodiment 2

[0032] 1. Sieve the steel slag tailings (chemical composition shown in Table 1) of Anshan Iron and Steel Co., Ltd., and select particles with a particle size of 40-100 mesh for fine grinding to achieve a specific surface area of 3000cm 2 / g, the specific surface area is 2200cm 2 / g desulfurized gypsum is heat-treated at 150°C for 2.5 hours, and all raw materials are mixed according to the following parts by weight:

[0033] Steel slag tailings 55 parts

[0034] 45 parts of desulfurized gypsum

[0035] Whisker plaster 3 parts

[0036] 0.3 parts of water glass

[0037] 3 parts quicklime

[0038] 3 parts alum

[0039] 2. After mixing and stirring the above raw materials for 20 minutes, according to the mass ratio of raw materials and water of 1:0.70, add water, mix and stir for 60 s, pour into the mold for 24 hours, demold and cure for 3 days.

[0040] 3. The compressive strength of the 20×20×20mm block reaches 9.33MPa, and the bulk density is 421 kg / m3 , meet the nationa...

Embodiment 3

[0042] 1. Sieve the steel slag tailings (chemical composition shown in Table 1) of Angang Steel, and select particles with a particle size of 40-100 mesh for fine grinding to achieve a specific surface area of 3600cm 2 / g, the specific surface area is 2800cm 2 / g desulfurized gypsum is heat-treated at 210°C for 1.8h, and all raw materials are mixed according to the following parts by weight:

[0043] Steel slag tailings 50 parts

[0044] Desulfurization gypsum 50 parts

[0045] Whisker plaster 4 parts

[0046] Water glass 0.2 parts

[0047] Quicklime 4 parts

[0048] 4 parts alum

[0049] 2. After mixing and stirring the above raw materials for 35 minutes, add water according to the mass ratio of raw materials and water of 1:0.60, mix and stir for 100 s, pour into the mold for 24 hours, demold and cure for 3 days.

[0050] 3. The compressive strength of the 20×20×20mm block reaches 9.44MPa, and the bulk density is 410 kg / m 3 , meet the national standard GB8624-2006 A1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com