Easily-dyed aliphatic polyurethane resin and preparation method thereof

An aliphatic polyurethane and easy-dyeing technology, applied in the field of polyurethane resin, can solve the problems of poor levelness and color fastness, and difficult to dye, and achieve the effects of improved dyeing performance, good levelness, and easy dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

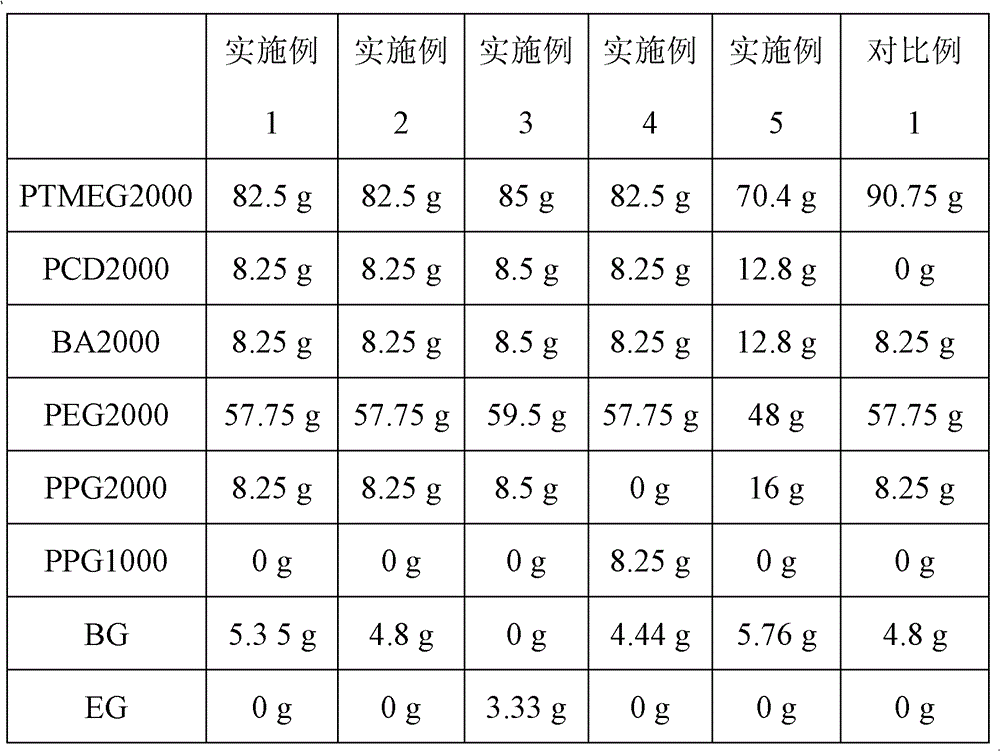

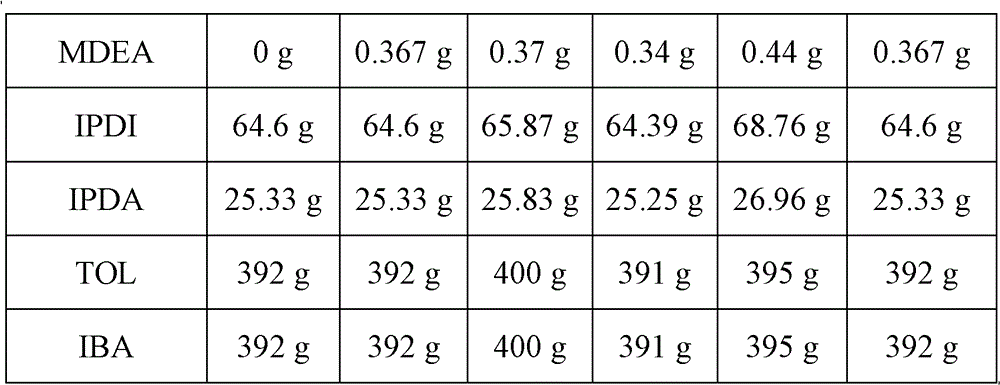

Embodiment 1

[0040] 1. Raw material ratio

[0041] Number-average molecular weight is 8.25g of polytetramethylene glycol adipate copolyester diol (BA2000) of 2000,

[0042] Number average molecular weight is 8.25g of polycarbonate diol (PCD2000) of 2000,

[0043] Number average molecular weight is 82.5g of polytetrahydrofuran ether glycol (PTMEG2000) of 2000,

[0044] Number average molecular weight is 57.75g of polyethylene glycol (PEG2000) of 2000,

[0045] Number average molecular weight is 8.25g of polypropylene glycol (PPG2000) of 2000,

[0046] 1,4-butanediol (BG) 5.35g,

[0047] Isophorone diisocyanate (IPDI) 64.6g,

[0048] Isophoronediamine (IPDA) 25.33g,

[0049] Toluene (TOL) 392g,

[0050] Isobutanol (IBA) 392g.

[0051] 2. Preparation method

[0052] (1) Pre-polymerization: Put 8.25g of BA2000, 8.25g of PCD2000, 82.5g of PTMEG2000, 57.75g of PEG2000, 8.25g of PPG2000, 5.35g of BG and 55.1g of IPDI into the reactor at 90℃~110℃ for 4~5 hours ;

[0053](2) Add the remai...

Embodiment 2

[0056] 1. Raw material ratio

[0057] Number-average molecular weight is 8.25g of polytetramethylene glycol adipate copolyester diol (BA2000) of 2000,

[0058] Number average molecular weight is 8.25g of polycarbonate diol (PCD2000) of 2000,

[0059] Number average molecular weight is 82.5g of polytetrahydrofuran ether glycol (PTMEG2000) of 2000,

[0060] Number average molecular weight is 57.75g of polyethylene glycol (PEG2000) of 2000,

[0061] 8.25g of polypropylene glycol (PPG2000) with a molecular weight of 2000,

[0062] 1,4-butanediol (BG) 4.8g,

[0063] Isophorone diisocyanate (IPDI) 64.6g,

[0064] Isophoronediamine (IPDA) 25.33g,

[0065] Toluene (TOL) 392g,

[0066] Isobutanol (IBA) 392g.

[0067] 2. Preparation method

[0068] (1) Pre-polymerization: put BA20008.25g, PCD20008.25g, PTMEG200082.5g, PEG200057.75g, PPG20008.25g, BG 4.8g, MDEA0.367g, IPDI 58.3g and TOL 25g into the reactor, at 110℃~ 120°C, react for 3 to 4 hours;

[0069] (2) Add the remaining...

Embodiment 3

[0072] 1. Raw material ratio

[0073] Number-average molecular weight is 8.5g of polytetramethylene glycol adipate copolyester diol (BA2000) of 2000,

[0074] The number average molecular weight is 2000 polycarbonate diol PCD20008.5g,

[0075] Number average molecular weight is 85g of polytetrahydrofuran ether glycol (PTMEG2000) of 2000,

[0076] Number average molecular weight is 59.5g of polyethylene glycol (PEG2000) of 2000,

[0077] The number average molecular weight is 8.5g of polypropylene glycol (PPG2000) of 2000,

[0078] Ethylene glycol (EG) 3.33g,

[0079] N-methylethylene glycol amine (MDEA) 0.37g,

[0080] Isophorone diisocyanate (IPDI) 65.87g,

[0081] Isophoronediamine (IPDA) 25.83g,

[0082] Toluene (TOL) 400g,

[0083] Isobutanol (IBA) 400 g.

[0084] 2. Preparation method

[0085] (1) Pre-polymerization: put BA20008.5g, PCD20008.5g, PTMEG200085g, PEG200059.5g, PPG20008.5g, EG 3.33g, MDEA0.37g, IPDI 56.23g and TOL 12g into the reactor, at 95℃~105℃ Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com