Novel segmented copolymer and preparation method thereof

A technology of block copolymers and oligomers, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of reduced production cost, low activity, long reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

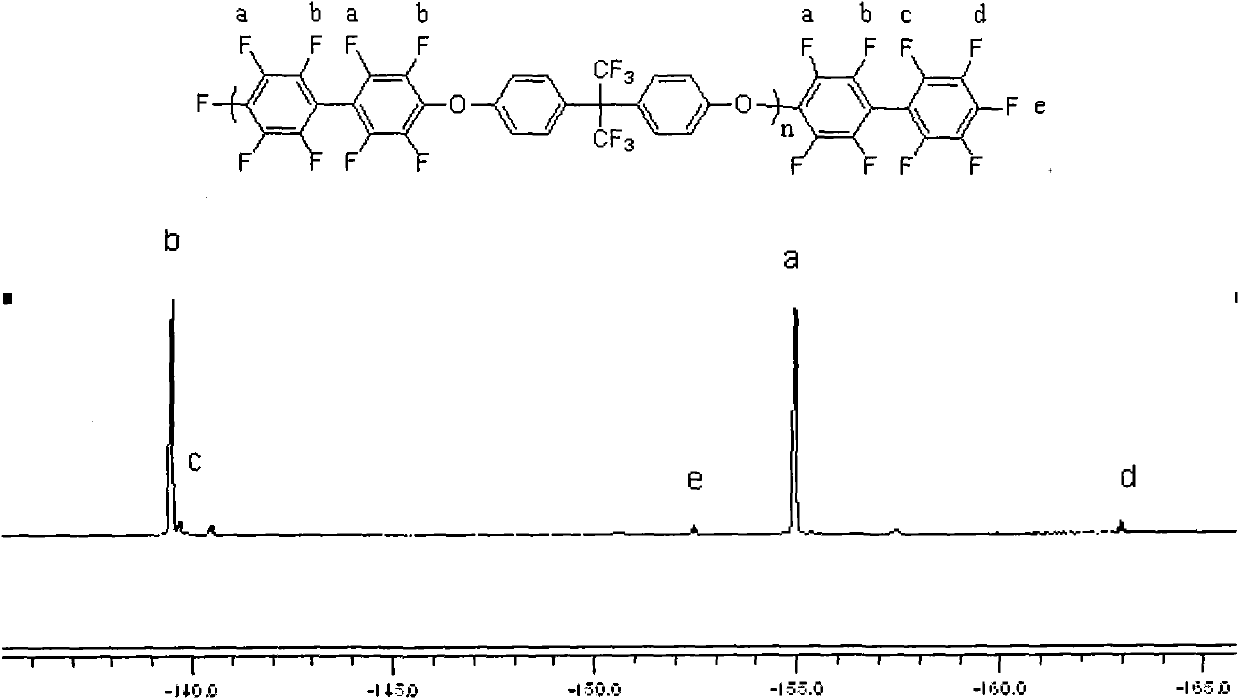

[0070] 1.1 Synthesis of hydrophobic oligomer 6FBisAF

[0071] In a 100mL three-neck flask equipped with a thermometer, a nitrogen pipe, a condensing water separator, and a stirrer, first add 20mL of N-methylpyrrolidone, then add hexafluorobisphenol A (2.29g, 6.82mmol), and then add potassium carbonate (1.18g, 8.53mmol), then add 10mL toluene, start stirring, raise the temperature to 150°C, the system is azeotropic at this temperature, react at this temperature for 2 hours to remove the water in the system, and then steam the reaction system Toluene in. Then the temperature was lowered to 50°C, and perfluorobiphenyl (2.39g, 7.16mmol) was added, and the reaction was heated up to 100°C, and reacted at this temperature for 3.5 hours. Then the reaction was cooled to room temperature, and the polymer was poured into a mixture of 400mL methanol and water (volume ratio methanol / water=1:1), left to stand for 10 minutes, stirred for another five minutes, filtered, washed twice with wat...

Embodiment 2

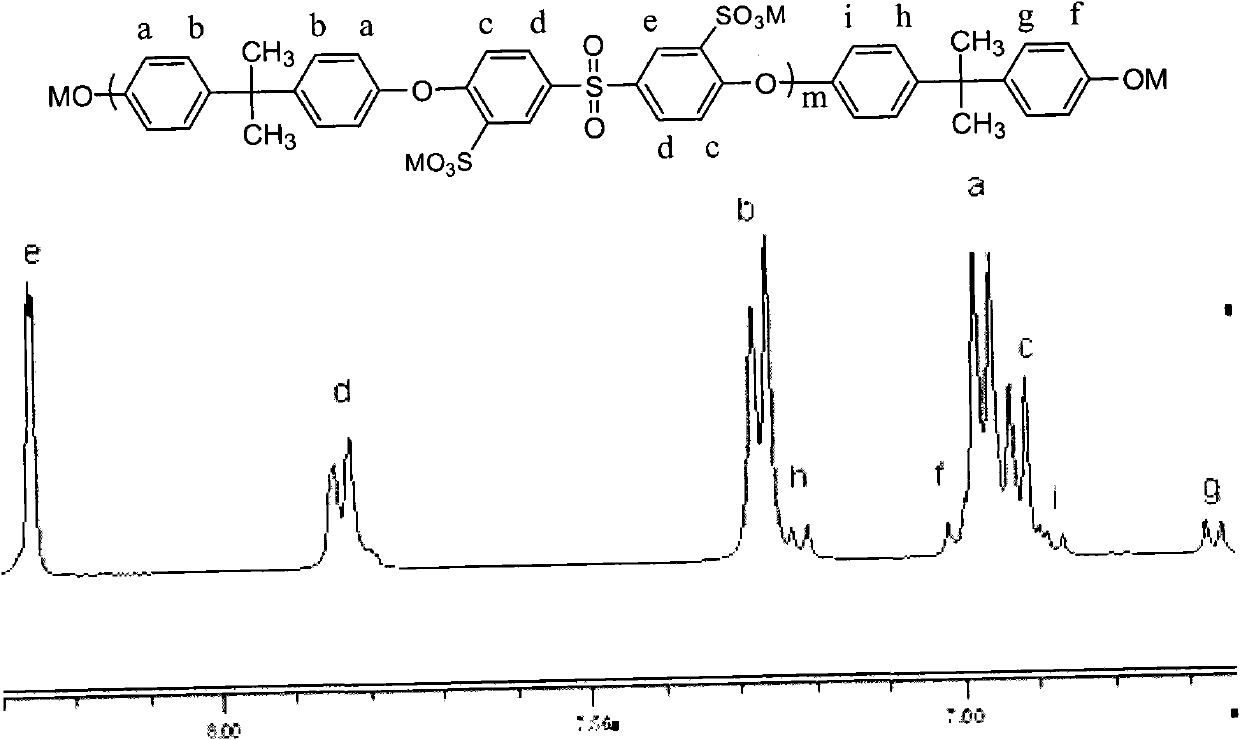

[0089] The block copolymer of the present invention is prepared by the same method as in Example 1, except that: in step (1), the hydrophobic oligomer 6FBi sAF is made of perfluorobiphenyl and hexafluorobisphenol A in a ratio of 1.07:1 The mol ratio synthetic; In the step (2), hydrophilic oligomer BPAS100 is by bisphenol A and 3,3 '-sodium disulfonate base-4,4'-dichlorodiphenyl sulfone according to the mol ratio of 1.1:1 Synthesis; In step (3), the hydrophobic oligomer 6FBi sAF and the hydrophilic oligomer BPAS100 were synthesized at a molar ratio of 1.2:1, and the reaction time was changed to 3 days.

[0090] In the obtained block copolymer of the present invention, m and n were 12 and 11, respectively. The viscosity of the synthesized block copolymer was measured: the reduced viscosity was 0.82dL / g.

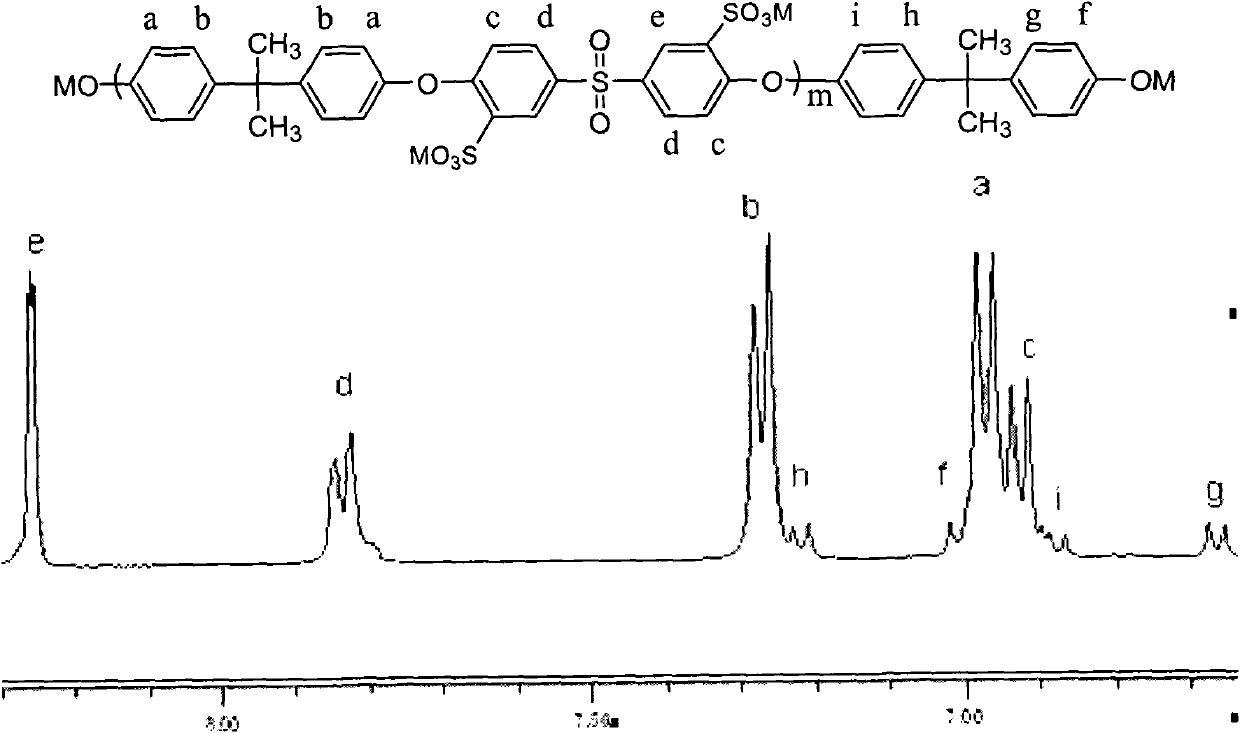

Embodiment 3

[0092] The block copolymer of the present invention is prepared by the same method as in Example 1, except that: in step (1), the hydrophobic oligomer 6FBisAF is made of perfluorobiphenyl and hexafluorobisphenol A at a ratio of 1.11:1 Molar ratio is synthesized; In step (2), hydrophilic oligomer BPAS100 is synthesized by bisphenol A and 3,3'-sodium disulfonate base-4,4'-dichlorodiphenyl sulfone in a molar ratio of 1.2:1 ; In step (3), the reaction time becomes 4 days.

[0093] In the obtained block copolymer, m and n were 8 and 9, respectively. The viscosity of the synthesized block copolymer was measured: the reduced viscosity was 0.85dL / g.

[0094] According to the novel block copolymer of the present invention, since the reaction can be carried out at a relatively low temperature and the reaction time is shortened, the cost can be significantly reduced, and it can be widely used in industry. Moreover, the novel block copolymer synthesized by the present invention belongs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reduced viscosity | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com