Preparation method of lactic acid

A technology for inoculating lactic acid bacteria and lactic acid, applied in the field of biomass chemical engineering, can solve the problems of lack of efficient utilization methods, inability to utilize non-starch polysaccharides, etc., and achieve the effects of low price, high compatibility, and high lactic acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

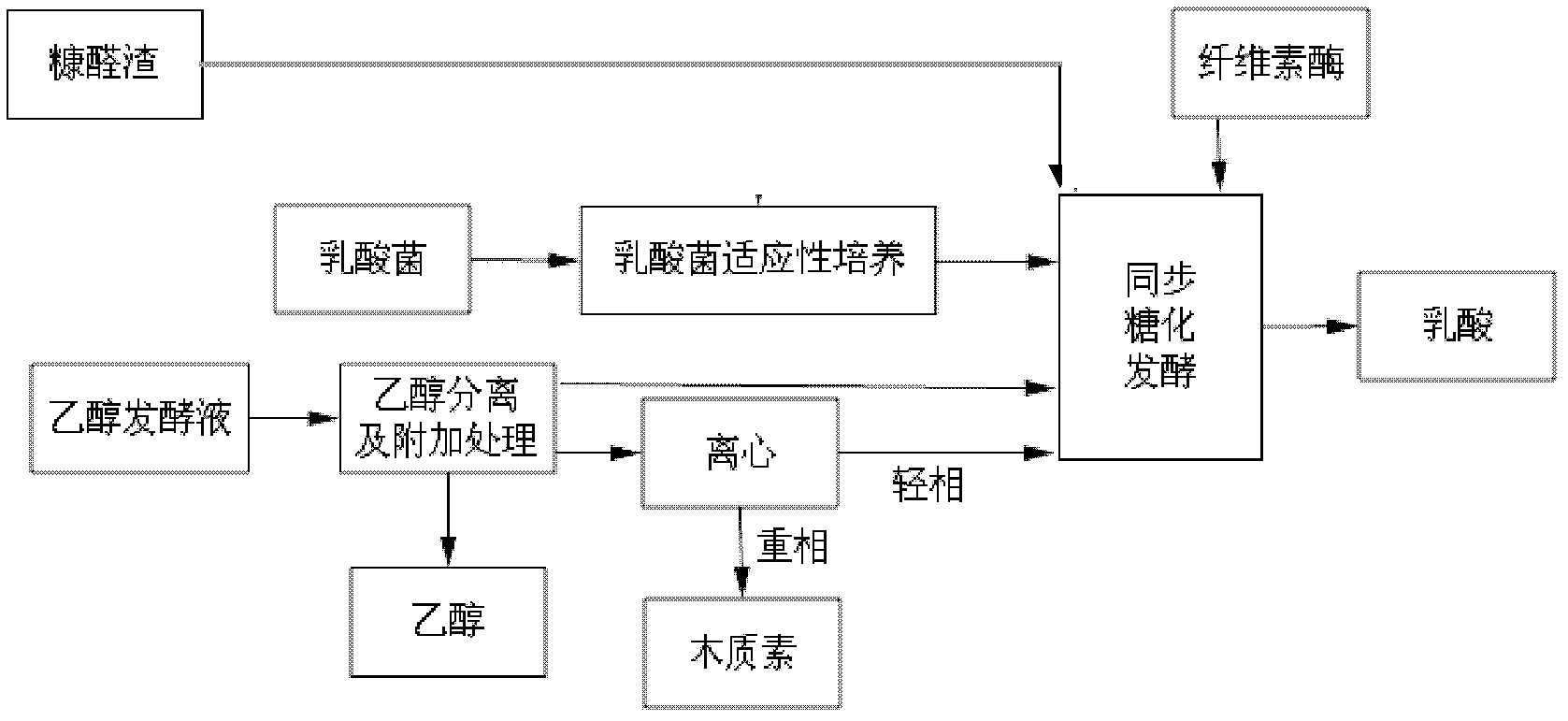

Method used

Image

Examples

Embodiment 1

[0032] Using 20% corn hydrolyzate, adding 0.2% yeast, ethanol fermentation for 30h, the fermented liquid contains 27.6g / L sugar and 45.2g / L ethanol. Take 1L of the fermentation residue after the ethanol has been separated and heat it at 121°C for 60min. Lactic acid bacteria adaptive culture system contains furfural residue 5g / l, KH 2 PO 4 0.5g / l, MgSO 4 ·7H 2 O 0.5g / l, NaCl 0.1g / l and CaCO 3 20g / l, prepared with water. The culture temperature of the adaptive culture was 32°C, the culture time was 36 hours, and the pH value was 6.0. Take 0.17L of the treated fermentation residue and add it to the fermenter, add 5% (w / v) furfural slag for fermentation, make up the total fermentation volume to 1L with water, solid CaCO 3 5% (w / v), the addition of cellulase was 15FPU / g furfural residue, the addition of adaptive lactic acid bacteria was 1.25g / L, the fermentation temperature was 42°C, the pH value was 6.0, and the lactic acid was 31.0g / L after 120h, producing The ratio is...

Embodiment 2

[0034] Using 20% corn hydrolyzate, adding 0.2% yeast, ethanol fermentation for 30h, the fermented liquid contains 27.6g / L sugar and 45.2g / L ethanol. Take 1L of the fermentation residue after the ethanol has been separated and heat it at 100°C for 10min. Lactic acid bacteria adaptive culture system contains furfural residue 5g / l, KH 2 PO 4 0.5g / l, MgSO 4 ·7H 2 O 0.5g / l, NaCl 0.1g / l and CaCO 3 20g / l, prepared with water. The culture temperature of the adaptive culture was 32°C, the culture time was 36 hours, and the pH value was 6.0. Take 0.17L of the treated fermentation residue and add it to the fermenter, add 5% furfural slag for fermentation, make up the total fermentation volume to 1L with water, solid CaCO 3 , 5% (w / v), cellulase addition 15FPU / g furfural slag, adaptive lactic acid bacteria addition 1.0g / L, fermentation temperature 38°C, pH 6.0, lactic acid after 108h was 27.9g / L, The yield was 89.9% (calculated based on the monosaccharide in the raffinate and th...

Embodiment 3

[0036] Using 20% corn hydrolyzate, adding 0.2% yeast, ethanol fermentation for 30h, the fermented liquid contains 27.6g / L sugar and 45.2g / L ethanol. Add 1 mol / L hydrochloric acid to 1L of the fermented residue from which ethanol has been separated, place it at 25°C for 1 hour, heat at 100°C for 10 minutes, and then adjust it to neutral with 10% NaOH for later use. Lactic acid bacteria adaptive culture system contains furfural residue 5g / l, KH 2 PO 4 0.5g / l, MgSO 4 ·7H 2 O 0.5g / l, NaCl 0.1g / l and CaCO 3 20g / l, prepared with water. The culture temperature of the adaptive culture was 32°C, the culture time was 36 hours, and the pH value was 6.0. Take 0.17L of the treated fermentation residue and add it to the fermenter, add 5% (w / v) furfural slag for fermentation, make up the total fermentation volume to 1L with water, solid CaCO 3 , 5% (w / v), cellulase addition amount 20FPU / g furfural residue, adaptive lactic acid bacteria addition amount 1.5g / L, fermentation temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com