Method for leaching limonitic laterite nickel ore

A technology of lateritic nickel ore and limonite, applied in the direction of improving process efficiency, etc., can solve the problems of high equipment requirements, high impurity content in leaching liquid, poor selectivity, etc., to reduce the loss of nickel and cobalt, and improve the comprehensive utilization rate of iron , Good leaching selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

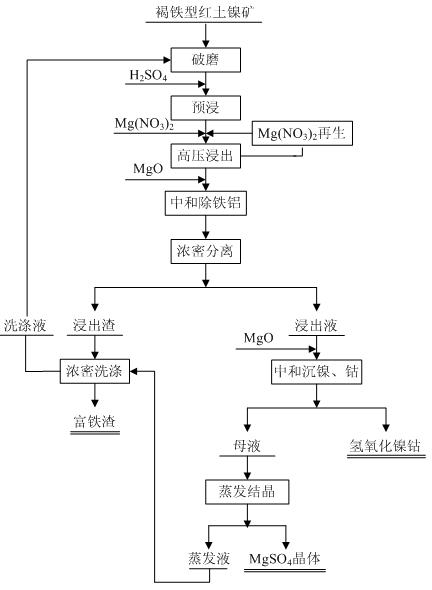

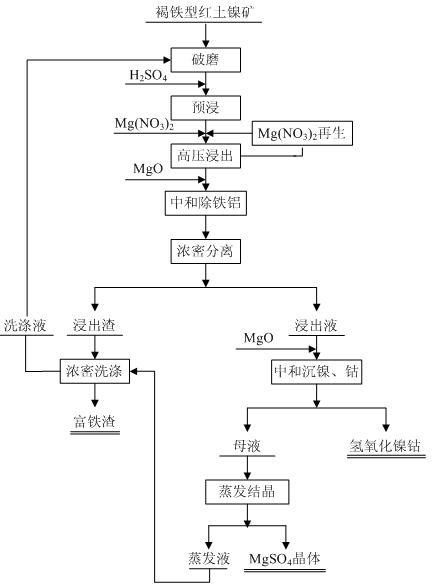

Image

Examples

Embodiment 1

[0039]The raw ore is crushed and wet-milled to obtain lateritic nickel ore with a particle size of less than 74 μm, accounting for 75%. The mass concentration of the slurry is 30%. Concentrated sulfuric acid with a mass fraction of 98% is added. The amount of acid added is 350 kg / t dry base ore. Pre-soak at 80°C for 1 hour; after the pre-soaking, add solid magnesium nitrate at a rate of 60 kg / t dry base ore, then raise the temperature to 230°C for pressure leaching, the leaching pressure is 2.5 Mpa, and the leaching time is 5 h , the liquid-solid ratio is 3:1 ml / g, the stirring speed is 500 rpm, wherein the leaching rate of nickel is 91.2%, the leaching rate of cobalt is 92.4%, and the leaching rate of iron is as low as 0.5%; the mass concentration of gas in the kettle is 20% The magnesia slurry is absorbed, and the pH value of the leached pulp is adjusted to 4.0 with a mass concentration of 20% magnesia slurry, and then after dense separation and 5-stage dense washing with a l...

Embodiment 2

[0041] The raw ore is crushed and wet-milled to obtain lateritic nickel ore with a particle size of less than 74 μm, accounting for 78%. The mass concentration of the slurry is 42%. Concentrated sulfuric acid with a mass fraction of 98% is added. The amount of acid added is 260 kg / t dry base ore, heated to 75°C, pre-soak for 1.0 h; after the pre-soaking, add regenerated magnesium nitrate solution and magnesium nitrate solid, equivalent to a total amount of magnesium nitrate solid addition of 70 kg / t dry base ore, and then raise the temperature to 220°C for pressure leaching, the leaching pressure The leaching rate was 2.5 Mpa, the leaching time was 2 h, the liquid-solid ratio was 2:1 ml / g, and the stirring speed was 500 rpm. The leaching rate of nickel was 90.7%, that of cobalt was 91.0%, and that of iron was as low as 0.4%. The internal gas is absorbed with magnesia slurry with a mass concentration of 18%, and the leached pulp is adjusted to a pH value of 4.0 with a magnesia s...

Embodiment 3

[0043] The raw ore is crushed and wet-milled to obtain lateritic nickel ore with a particle size of less than 74 μm, accounting for 85%. The mass concentration of the slurry is 20%. Concentrated sulfuric acid with a mass fraction of 98% is added. to 60°C, pre-soak for 0.5 h; after pre-soaking, add regenerated magnesium nitrate solution and solid magnesium nitrate, equivalent to a total amount of magnesium nitrate solids added of 80 kg / t dry base ore, and then raise the temperature to 200°C for pressure leaching, the leaching pressure The leaching rate was 1.8 Mpa, the leaching time was 3 h, the liquid-solid ratio was 6:1 ml / g, and the stirring speed was 800 rpm, the leaching rate of nickel was 94.2%, the leaching rate of cobalt was 95.4%, and the leaching rate of iron was as low as 0.8%; The internal gas is absorbed with magnesia slurry with a mass concentration of 30%, and the leached pulp is adjusted to a pH value of 3.8 with a magnesia slurry with a mass concentration of 30%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com