Accumulation type grooved-gate diode

A diode and accumulation type technology, applied in the field of semiconductor diode device structure, can solve the problems of easy breakdown, narrow application range, low reverse withstand voltage value, etc., and achieve the improvement of reverse recovery characteristics and forward conduction characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

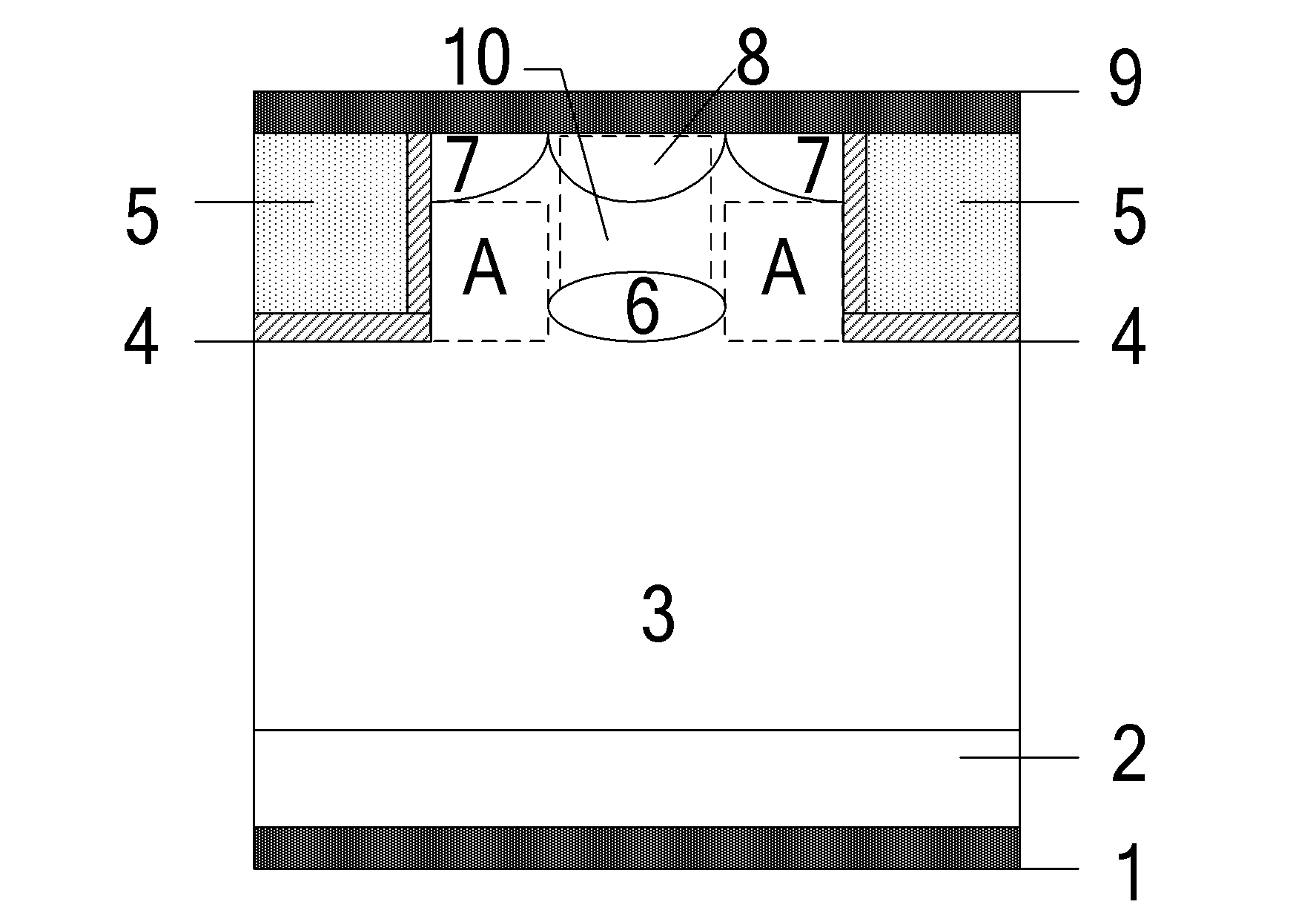

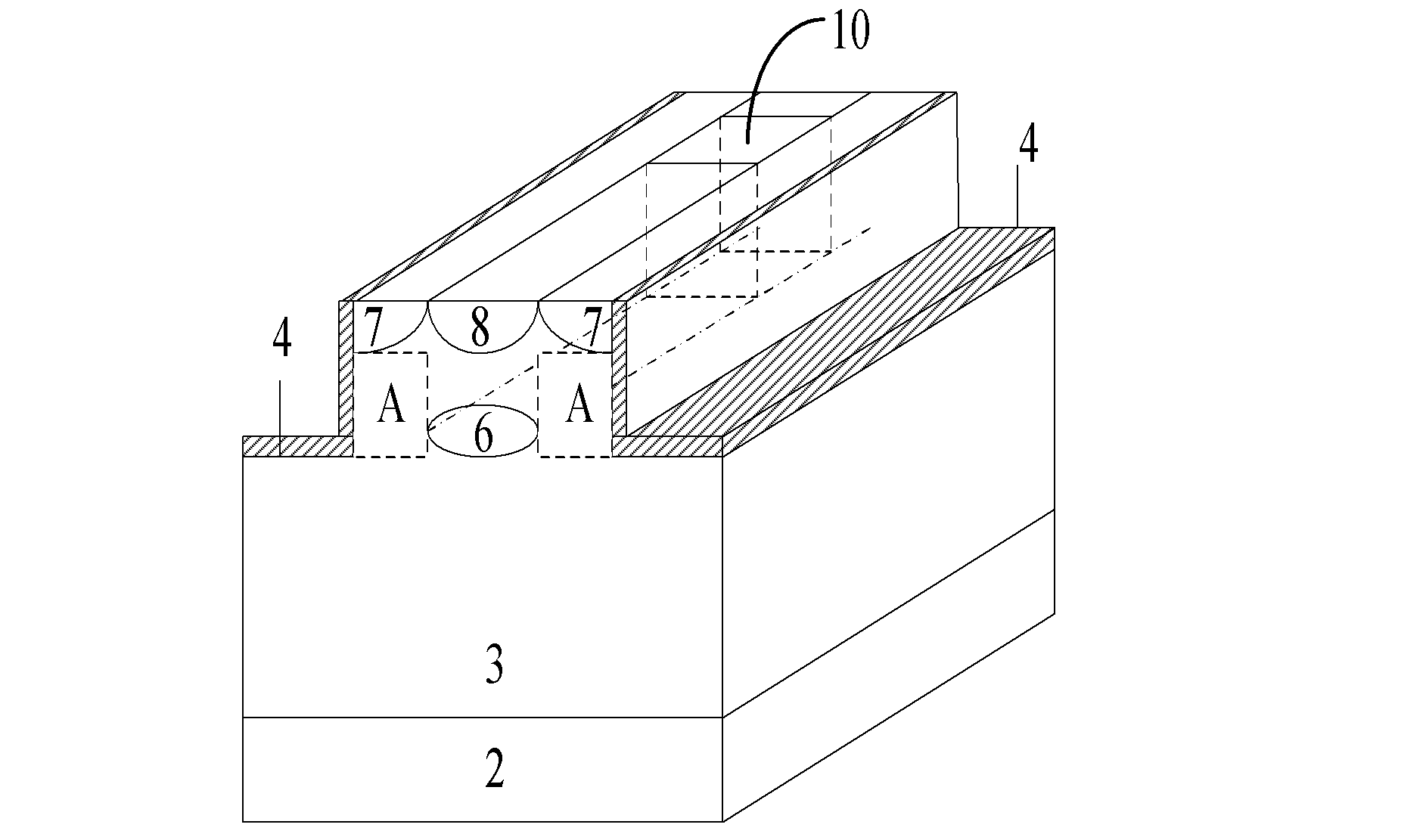

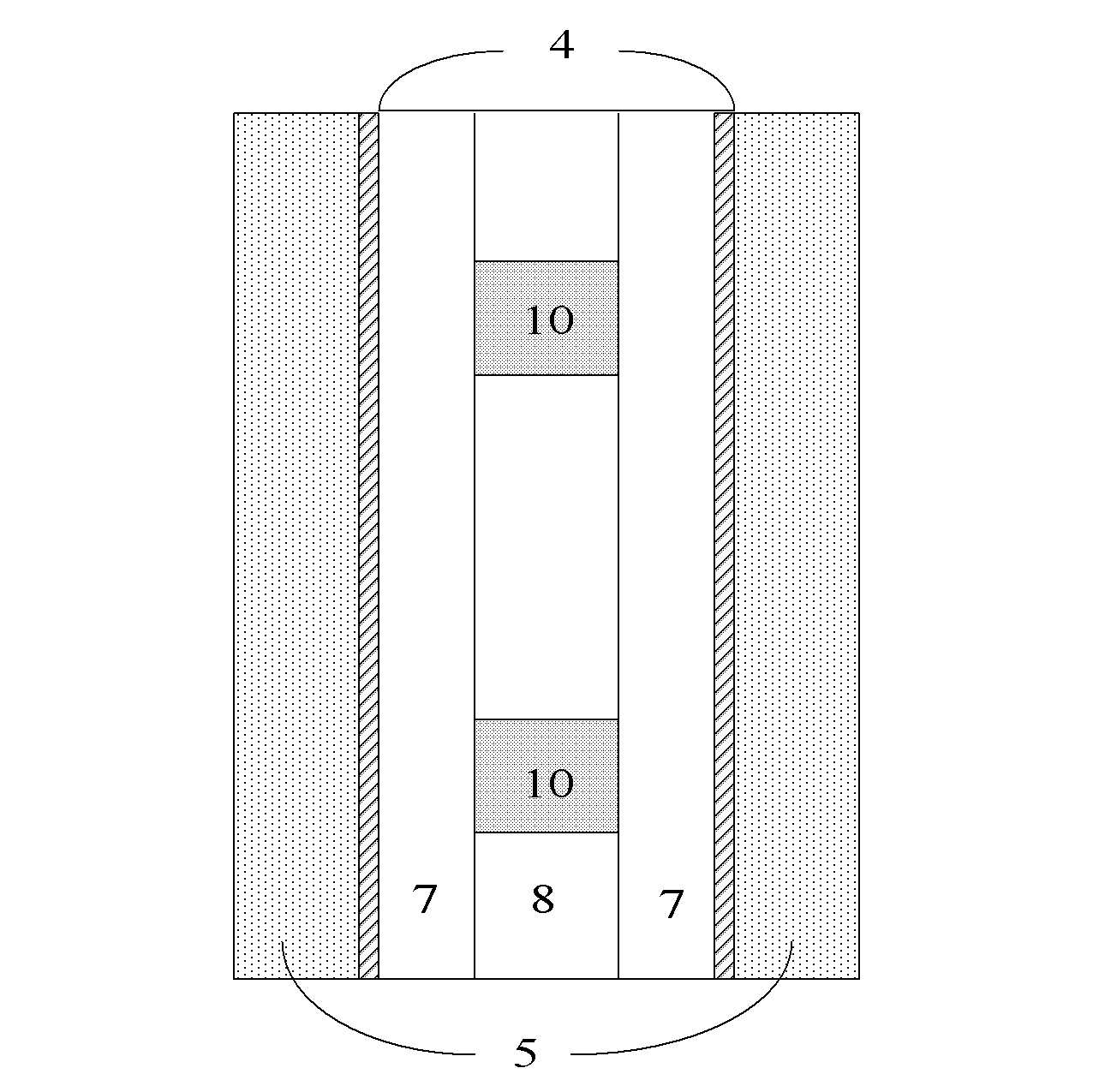

[0019] An accumulation type trench gate diode, the structure of which is as follows Figure 1~4 shown, including N + Substrate 2, located at N + The metallized cathode 1 on the back side of the substrate 2, located at N + N on the front side of substrate 2 - Drift region 3 and metallized anode 9 on top of the entire diode; in N - There is a grooved gate electrode 5 outside the two sides of the top of the drift region 3, and the two grooved gate electrodes 5 and N - The drift regions 3 are separated by respective silicon dioxide gate oxide layers 4; - There is a strip-shaped N-type heavily doped region 7 on both sides of the top of the drift region 3, and there is a strip-shaped P-type heavily doped region 8 between the two strip-shaped N-type heavily doped regions 7; N under the heavily doped region 8 and located in the middle region of the two silicon dioxide gate oxide layers 4 - There is a strip-shaped P-type buried layer region 6 in the drift region 3; there are sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com