Method for preparing BiFeO3 ferroelectric thin film photovoltaic battery on glass substrate

A ferroelectric thin film and glass substrate technology, which is applied in the manufacture of circuits, electrical components, and final products, to achieve the effects of wide sources, superior photovoltaic performance, and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

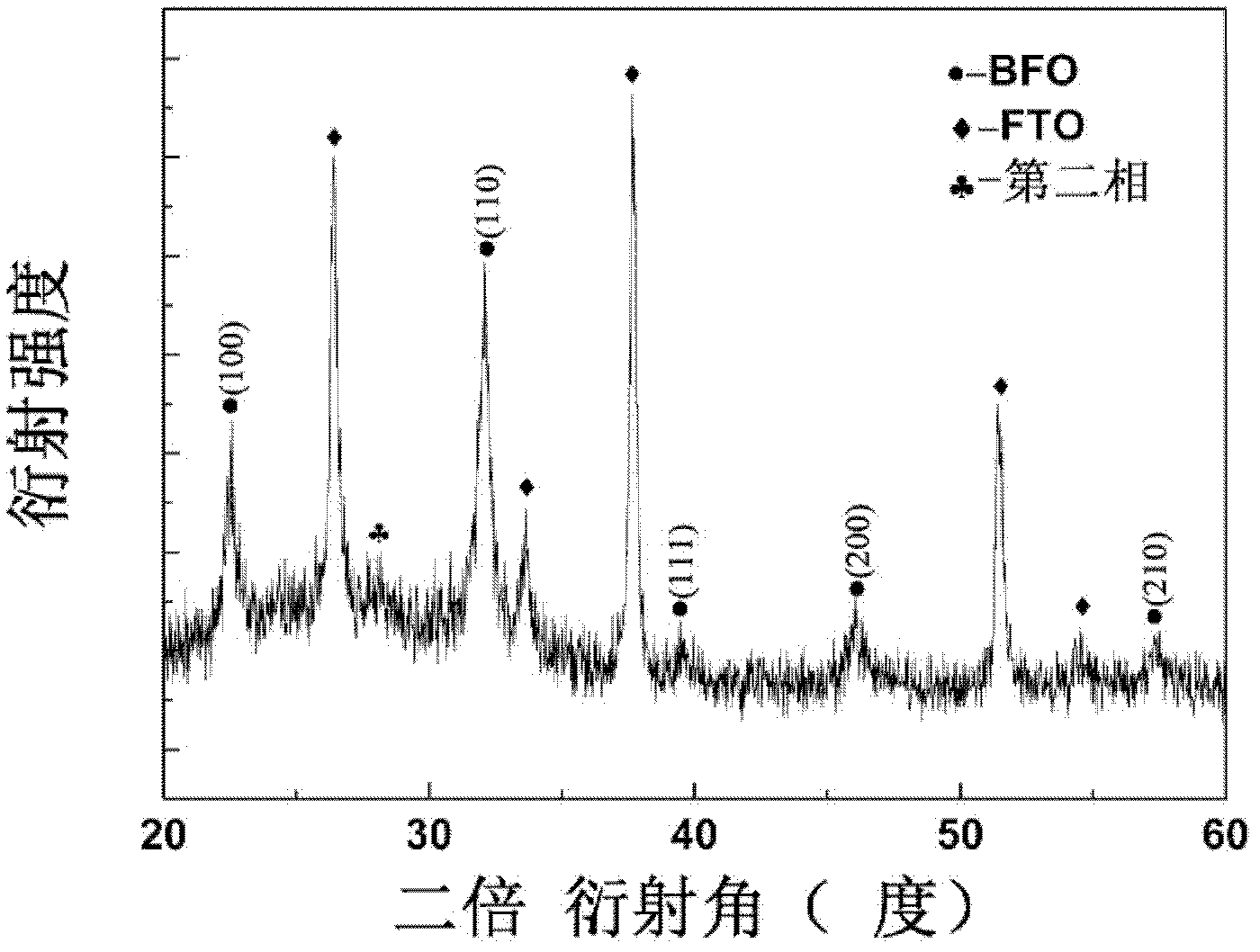

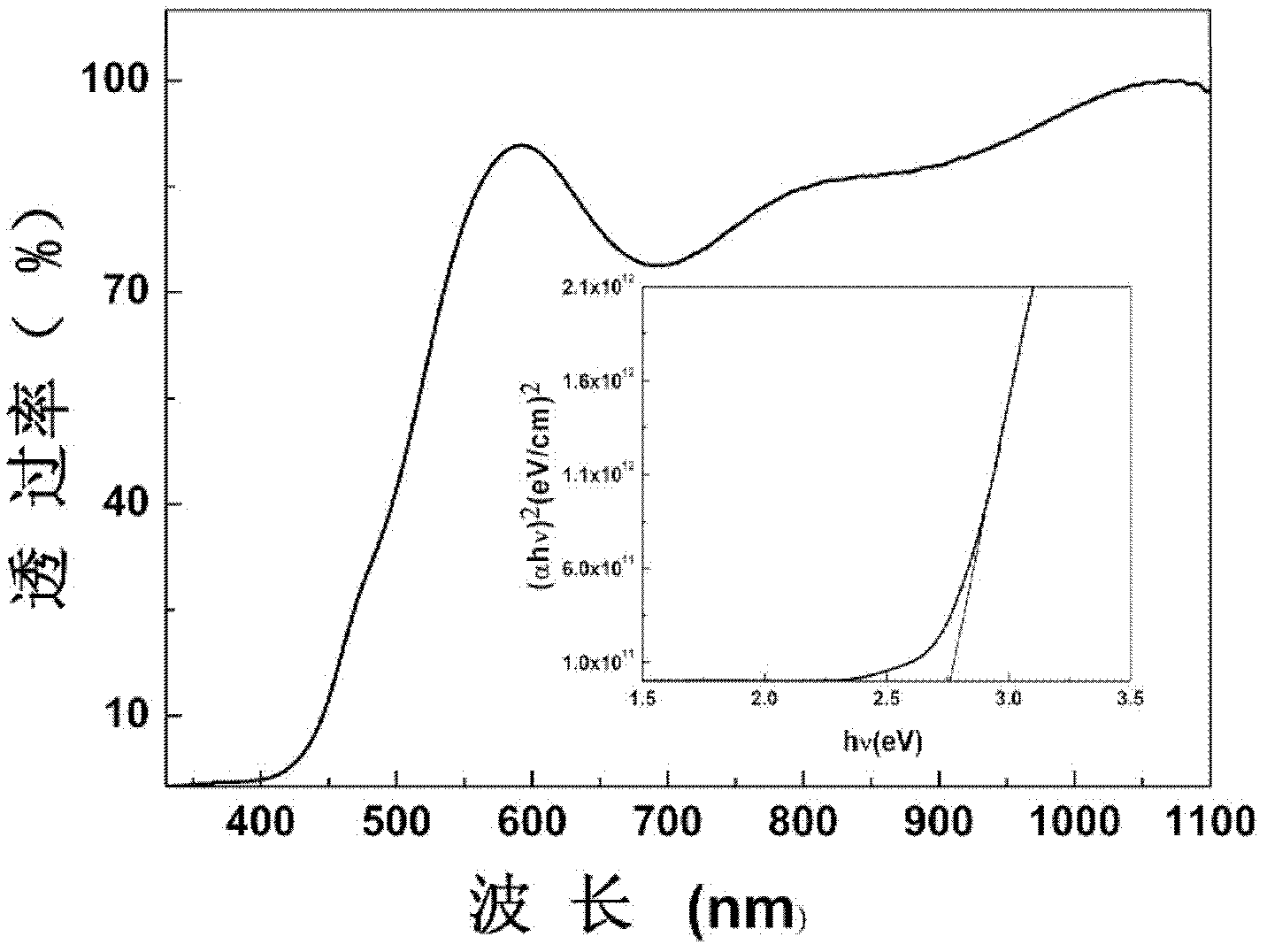

[0031] Bi(NO 3 ) 3 ·5H 2 O (excess 5%), Fe (NO 3 ) 3 9H 2 O is completely dissolved in ethylene glycol methyl ether at a molar ratio of 1:1, and a brownish-red clear and stable precursor solution is obtained. Films were then prepared by the gel-spin method. The condition of glue rejection is as follows: 10 seconds at 500 rpm and 30 seconds at 3000 rpm. After spinning the glue, the substrate with the precursor wet film was first dried on a hot plate at 200°C for 3 minutes, then calcined at 350°C for 5 minutes, and finally in O 2 Sintering at 500° C. for 5 minutes in a rapid annealing furnace under atmosphere. After the first layer was calcined, the first layer was annealed, and then annealed once every two layers, a total of 15 layers of glue were thrown, and the BFO ferroelectric thin film was obtained.

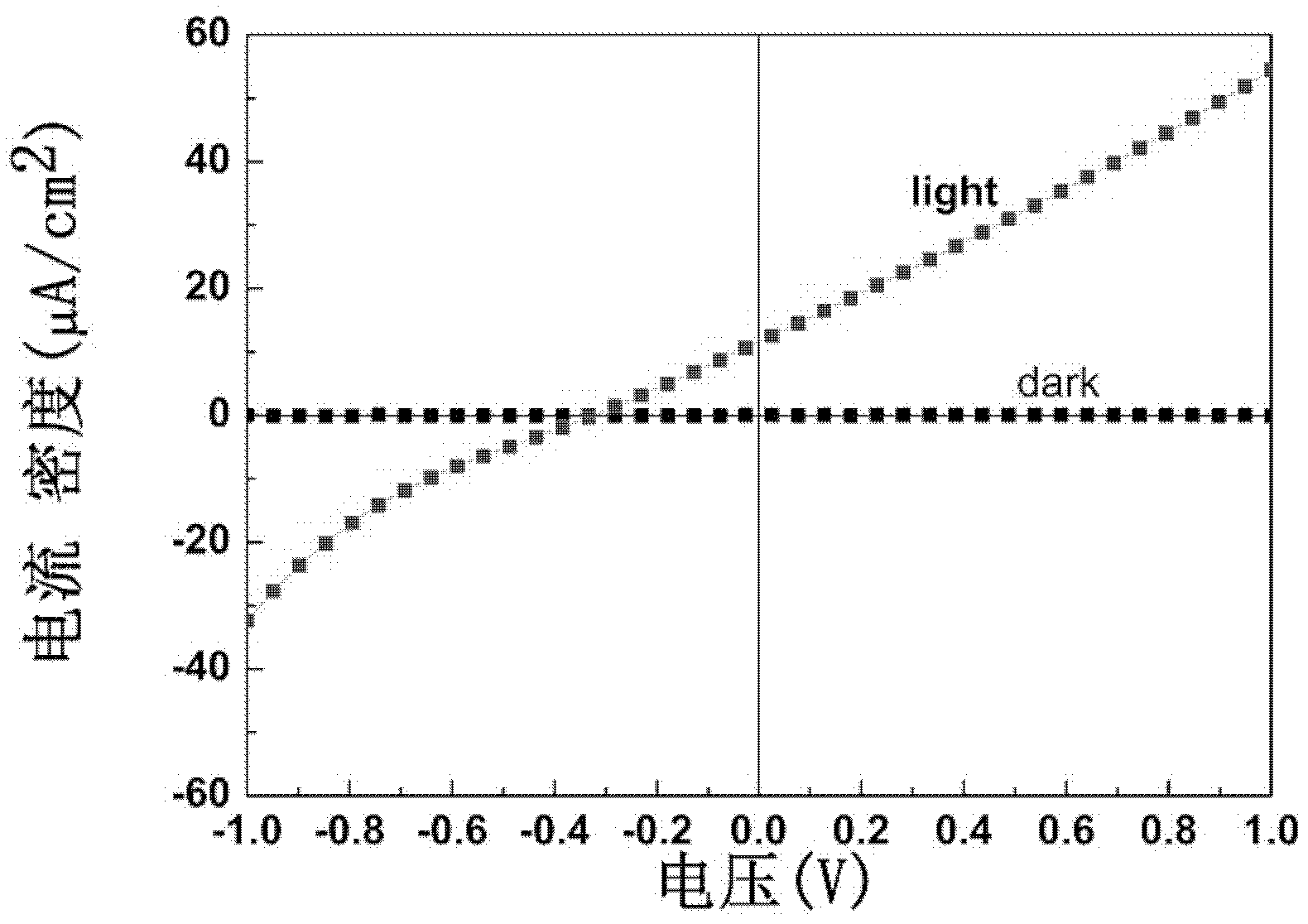

[0032] The prepared thin film is shielded by a mask plate with a hole of 0.5mm*0.5mm, and a 0.5mm*0.5mm Au upper electrode is deposited on the film surface by physica...

Embodiment 2

[0034] Bi(NO 3 ) 3 ·5H 2 O (excess 5%), Fe (NO 3 ) 3 9H 2 O is completely dissolved in ethylene glycol methyl ether at a molar ratio of 1:1, and a brownish-red clear and stable precursor solution is obtained. Films were then prepared by the gel-spin method. The condition of glue rejection is as follows: 10 seconds at 500 rpm and 30 seconds at 3000 rpm. After spinning the glue, the substrate with the precursor wet film was first dried on a hot plate at 200°C for 3 minutes, and then calcined at 350°C for 5 minutes. Finally at O 2 Sintering at 550° C. for 5 minutes in a rapid annealing furnace under atmosphere. After the first layer was calcined, the first layer was annealed, and then annealed once every two layers, a total of 15 layers of glue were thrown, and the BFO ferroelectric thin film was obtained.

[0035] The prepared thin film is shielded by a mask plate with a hole of 0.5mm*0.5mm, and a 0.5mm*0.5mm Au upper electrode is deposited on the film surface by physic...

Embodiment 3

[0037] Bi(NO 3 ) 3 ·5H 2 O (excess 5%), Fe (NO 3 ) 3 9H 2 O is completely dissolved in ethylene glycol methyl ether at a molar ratio of 1:1, and a brownish-red clear and stable precursor solution is obtained. Films were then prepared by the gel-spin method. The condition of glue rejection is as follows: 10 seconds at 500 rpm and 30 seconds at 3000 rpm. After spinning the glue, the substrate with the precursor wet film was first dried on a hot plate at 200°C for 3 minutes, and then calcined at 350°C for 5 minutes. Finally at O 2 Sintering at 600° C. for 5 minutes in a rapid annealing furnace under atmosphere. After the first layer was calcined, the first layer was annealed, and then annealed once every two layers, a total of 15 layers of glue were thrown, and the BFO ferroelectric thin film was obtained. The prepared thin film is shielded by a mask plate with a hole of 0.5mm*0.5mm, and a 0.5mm*0.5mm Au upper electrode is deposited on the film surface by physical sputte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com