Method for preparing lithium manganate anode material

A positive electrode material, lithium manganese oxide technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as uneven particle size of products, uneven heating of raw materials, and limited phase purity, so as to shorten the production cycle and improve products. The quality and product particles are uniform and consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Add lithium carbonate, manganese dioxide, and magnesium carbonate into deionized water according to the molar ratio of Li:Mn:Mg=0.6:1.1:0.015, stir and mix evenly.

[0019] 2) The obtained mixed solution is sprayed and pyrolyzed by a spray dryer to obtain a lithium manganate precursor powder in which the materials are evenly mixed.

[0020] 3) The obtained precursor powder is placed in a microwave sintering furnace, heated at 3kW for 7h, and then kept at 900W for 6h to obtain lithium manganate with good crystallinity and uniform phase.

[0021] 4) The lithium manganate sample obtained above was washed with pure water, filtered three times, dried at 140° C., and then passed through a 200-mesh sieve to obtain a lithium manganate cathode material with good quality.

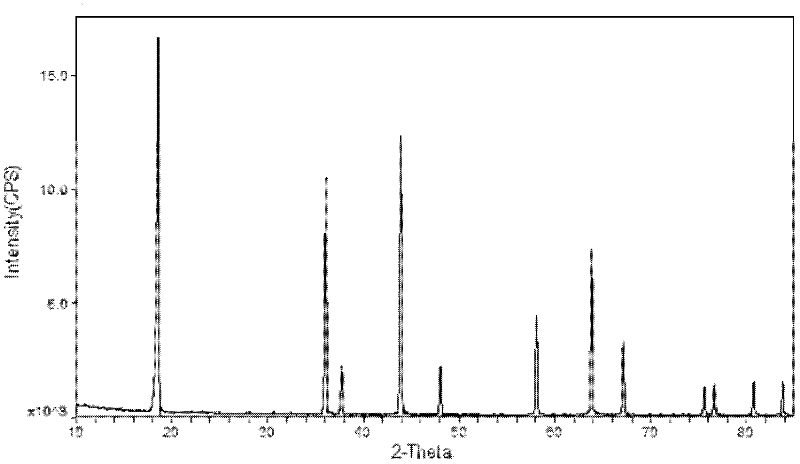

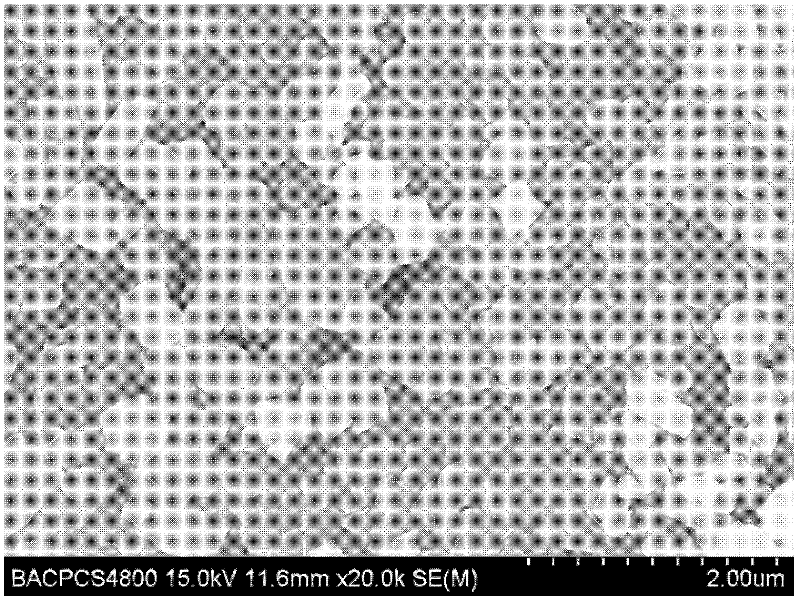

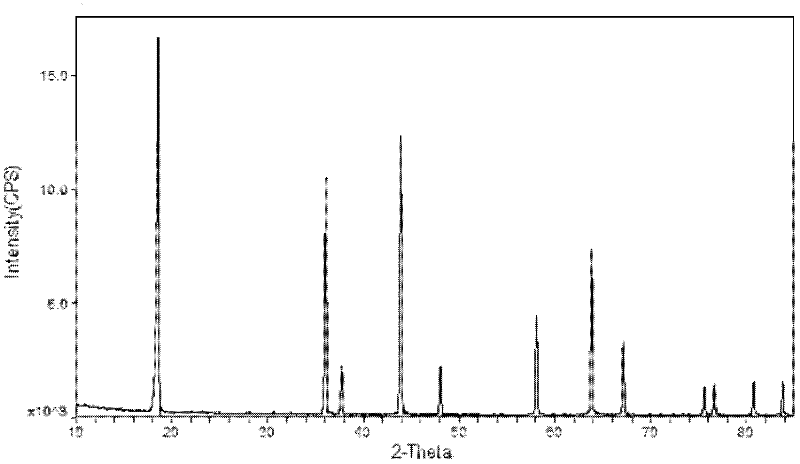

[0022] The present invention passes through the XRD figure of the sample of above-mentioned embodiment 1 as figure 1 As shown, the phase is very pure, the crystallinity is also very good, and its morpholog...

Embodiment 2

[0024] 1) Add lithium carbonate, manganese dioxide, and magnesium carbonate into deionized water according to the molar ratio of Li:Mn:Mg=0.5:1:0.01, stir, and mix evenly.

[0025] 2) The obtained mixed solution is sprayed and pyrolyzed by a spray dryer to obtain a lithium manganate precursor powder in which the materials are evenly mixed.

[0026] 3) The obtained precursor powder is placed in a microwave sintering furnace, heated at 2kW for 8h, and then maintained at 800W for 8h, and lithium manganate with good crystallinity and uniform phase is obtained.

[0027] 4) The obtained lithium manganate sample was washed with pure water, filtered three times, dried at 130° C., and then passed through a 200-mesh sieve to obtain a lithium manganate cathode material with good quality.

Embodiment 3

[0029] 1) Add lithium carbonate, manganese dioxide, and magnesium carbonate into deionized water according to the molar ratio of Li:Mn:Mg=0.65:1.2:0.02, stir and mix evenly.

[0030] 2) The obtained mixed solution is sprayed and pyrolyzed by a spray dryer to obtain a lithium manganate precursor powder in which the materials are evenly mixed.

[0031] 3) The obtained precursor powder is placed in a microwave sintering furnace, heated at 4kW for 6h, and then kept at 1000W for 5h, to obtain lithium manganate with good crystallinity and uniform phase.

[0032] 4) The lithium manganate sample obtained above was washed with pure water, filtered three times, dried at 150° C., and then passed through a 200-mesh sieve to obtain a lithium manganate cathode material with good quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com