Surface-emitting terahertz quantum cascade laser and manufacturing method thereof

A technology of surface emission and quantum cascade, applied in nano optics, structure of optical waveguide semiconductor, nanotechnology, etc. Effect of Divergence Angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

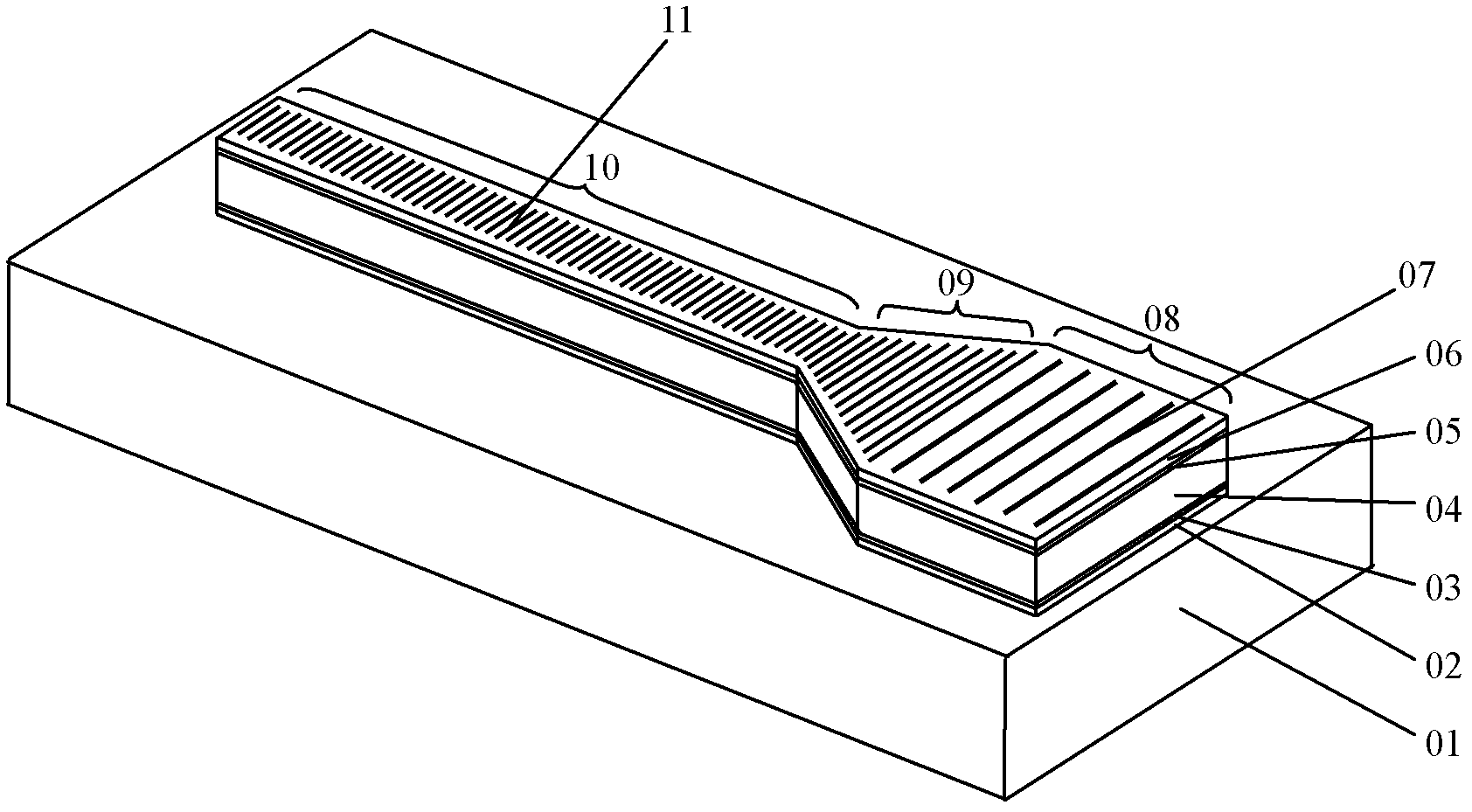

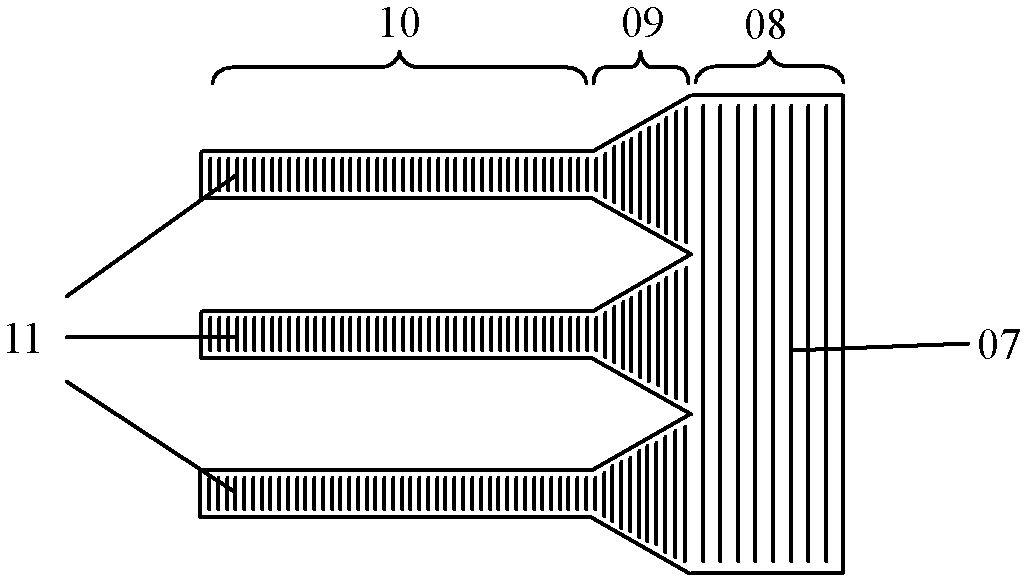

[0043] This embodiment provides a surface emitting terahertz quantum cascade laser, such as figure 1 As shown, it includes single-mode generating area waveguide 10, tapered coupling area waveguide 09 and surface emission area waveguide 08; The second-order grating 07 structure; single-mode terahertz seed light is generated inside the single-mode generating region waveguide 10, and the tapered coupling region waveguide 09 amplifies and couples the terahertz seed light to the surface emission region waveguide 08, and the surface emission region waveguide 08 enables The terahertz laser is emitted perpendicular to the surface of the substrate 01.

[0044] The entire device of the surface-emitting terahertz quantum cascade laser is made of GaAs, and a double-sided metal waveguide process is adopted. The single-mode generation region waveguide 10 of the laser, the tapered coupling region waveguide 09 and the surface emission region waveguide 08 are three parts. The whole is prepare...

Embodiment 2

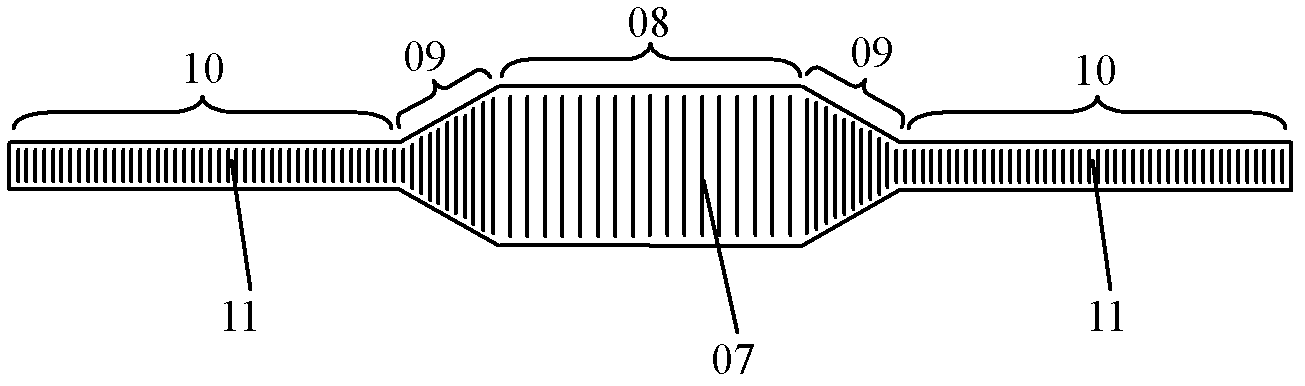

[0050] This embodiment provides a surface-emitting terahertz quantum cascade laser, which differs from the laser described in Embodiment 1 in that it adopts a double symmetric structure to achieve output power multiplication. Usually the two ends of the second-order grating terahertz quantum cascade laser along the grating arrangement direction need to make absorption edges, but the double symmetric structure can save the absorption edge. This also provides a method for second-order grating surface-emitting lasers, where first-order gratings can be etched at both ends of the waveguide to both increase the output power and suppress the lasing of the F-P cavity feedback mode.

[0051] Such as figure 2 As shown, it provides a schematic top view of a surface-emitting terahertz quantum cascade laser with a double symmetrical structure, omitting the schematic diagram of the substrate structure; waveguide 09 in the coupling region and waveguide 10 in the single-mode generation regi...

Embodiment 3

[0060] This embodiment provides a manufacturing method of the surface-emitting terahertz quantum cascade laser described in Embodiments 1 and 2. The manufacturing method adopts a double-sided metal waveguide process and includes the following steps:

[0061] Molecular beam epitaxy (MBE) growth of about 500 nm thick Al on semi-insulating GaAs substrate 0.5 Ga 0.5 As etch stop layer;

[0062] Molecular beam epitaxy (MBE) grows a heavily doped n-type GaAs upper contact layer with a thickness of about 500 nanometers on the etching barrier layer, and its function is to make the metal and GaAs form a non-alloy ohmic contact;

[0063] Molecular beam epitaxy (MBE) growth of an AlGaAs / GaAs alternating multilayer periodic structure active region on the upper contact layer, with a thickness of about 10 microns;

[0064] Molecular beam epitaxy (MBE) grows a heavily doped n-type GaAs lower contact layer of about 50 nanometers on the active region; then an electron beam evaporates a metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com