High-protein low-fat yogurt and preparation method thereof

A high-protein, low-fat technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of high dosage, ineffective improvement of yogurt, hypertrophy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

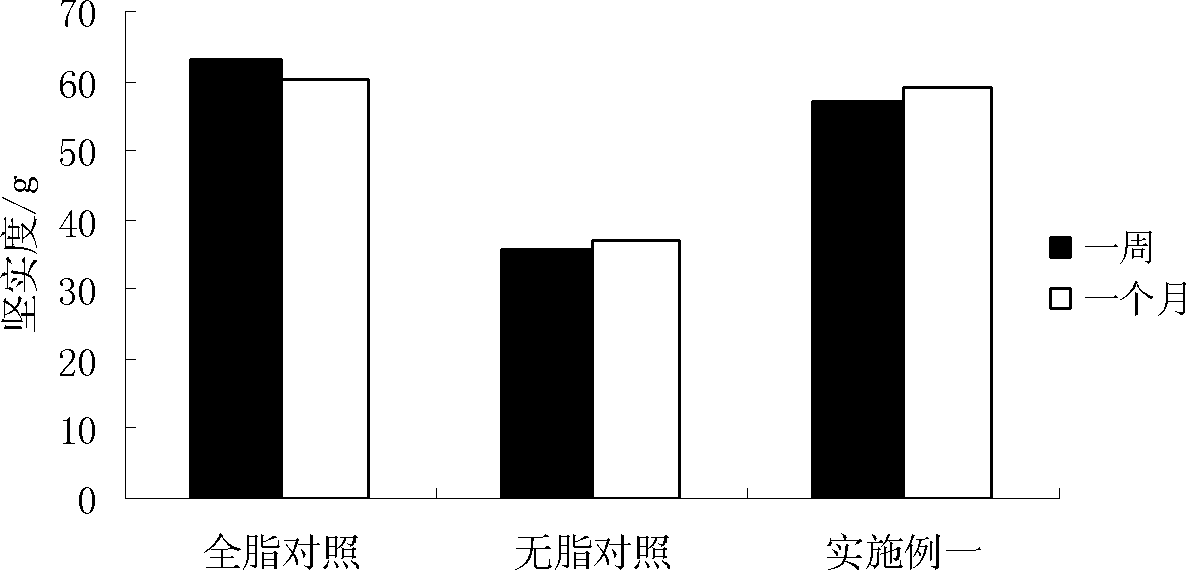

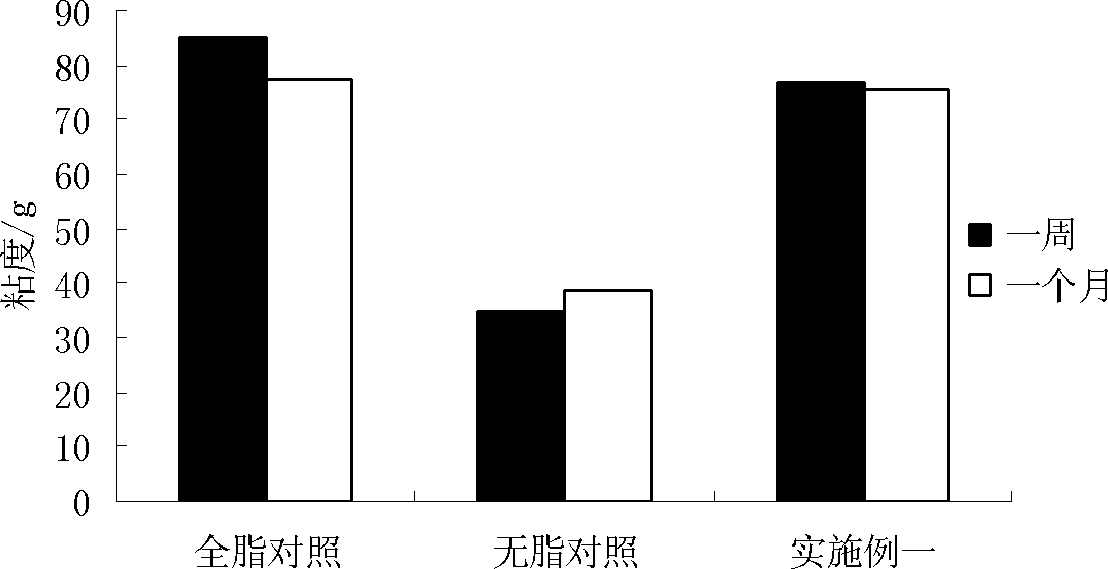

[0051] Example 1 Fat-free yogurt

[0052] Formula (Based on 1 ton):

[0053] Skimmed milk: 850 kg;

[0054] White sugar: 70 kg;

[0055] Gel type WPC (protein content is 78%, wherein β-lactoglobulin accounts for 65% of the total protein, calcium content is 1.2%): 20 kg;

[0056] Micronized casein (65% protein): 20 kg;

[0057] Yogurt essence: 20 grams;

[0058] Pure water: 20kg;

[0059] Straight-through yogurt starter (lactococcus and Lactobacillus bulgaricus): Appropriate amount.

[0060] All raw materials comply with relevant industry standards:

[0061] Skimmed milk: protein ≥ 2.95%, fat ≤ 0.4%, non-fat milk solids ≥ 8.5%;

[0062] White granulated sugar: in line with the national first-class standard;

[0063] Pure water meets national standards.

[0064] Preparation Process:

[0065]Ingredients: fully stir white sugar, gel-type WPC, micronized casein, 20% skim milk and pure water at 40°C, adjust the pH to 6.8, and mix well;

[0066] Homogenization: Mix the abo...

Embodiment 2

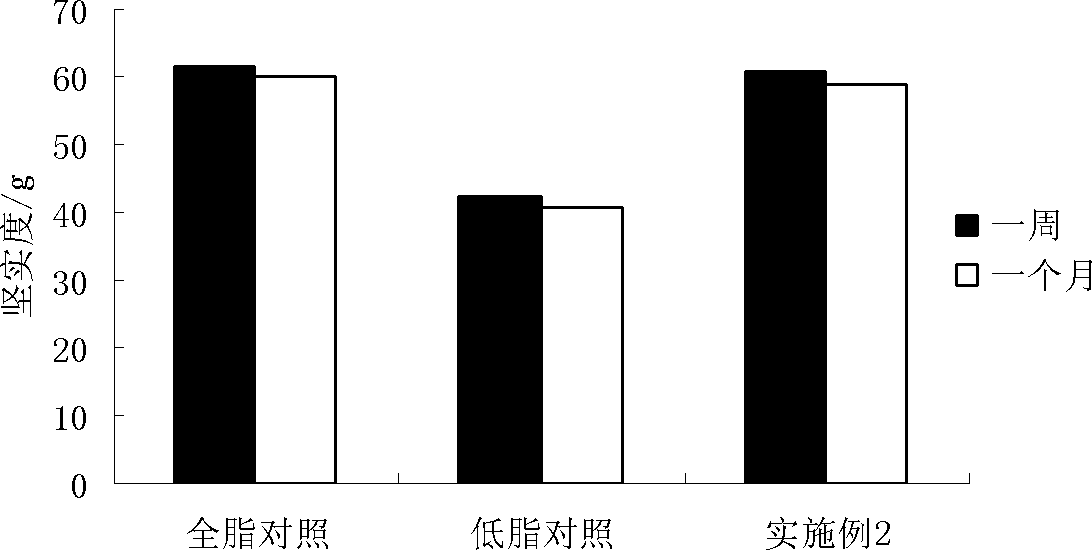

[0084] Example 2 Low-fat chocolate-flavored yogurt

[0085] Formula (according to 1 ton):

[0086] Skimmed milk: 800 kg;

[0087] White sugar: 60 kg;

[0088] Gel type WPC (protein content is 78%, wherein β-lactoglobulin accounts for 75% of the total protein, calcium content is 1.0%): 8 kg;

[0089] Micronized whey protein (55% protein): 15 kg;

[0090] Chocolate essence: 25 grams;

[0091] Straight-in yogurt starter (lactococcus and lactobacillus bulgaricus): appropriate amount;

[0092] Pure water: balance.

[0093] All raw materials comply with relevant industry standards:

[0094] Skimmed milk: protein ≥ 2.95%, fat 1.5%, non-fat milk solids ≥ 8.5%;

[0095] White granulated sugar: in line with the national first-class standard;

[0096] Pure water meets national standards.

[0097] Preparation Process:

[0098] Ingredients: Fully stir white sugar, gel-type WPC, micronized whey protein, chocolate essence and pure water at 45°C, adjust the pH to 7.0, and mix well; ...

Embodiment 3

[0113] Example 3 Low-fat strawberry fruit yogurt

[0114] Formula (according to 1 ton):

[0115] Skimmed milk: 780 kg;

[0116] High fructose syrup: 75 kg;

[0117] Gel type WPC (protein content is 76%, wherein β-lactoglobulin accounts for 88% of the total protein, calcium content is 0.7%): 30 kg;

[0118] Micronized soy protein (78% protein): 2 kg;

[0119] Strawberry diced: 50kg

[0120] Straight-in yogurt starter (lactococcus and lactobacillus bulgaricus): appropriate amount;

[0121] Pure water: balance.

[0122] All raw materials comply with relevant industry standards:

[0123] Skimmed milk: protein ≥ 2.95%, fat 2.3%, non-fat milk solids ≥ 8.5%;

[0124] White granulated sugar: in line with the national first-class standard;

[0125] Pure water meets national standards.

[0126] Preparation Process:

[0127] Ingredients: Fully stir white sugar, gel-type WPC, micronized soybean protein and pure water at 55°C to adjust the pH to 7.7, and mix well;

[0128] Homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com