Sand-shaped granulated creep feed product and preparation method thereof

A granular and sand-like technology is applied in the field of sand-like trough feed products and their preparation, which can solve the problems of poor feeding sanitation, high feed-to-meat ratio, polluted environment, etc., and achieves good palatability, large feed intake, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Formula:

[0056] Maltodextrin 10.0%;

[0057] Puffed broken rice 35.0%;

[0058] Soy protein concentrate powder 15.0%;

[0059] Plasma protein powder 4.0%;

[0060] Soluble intestinal membrane protein powder 2.5%;

[0061] Spray dried fish paste protein powder 2.5%;

[0062] High Protein Whey Powder 20.0%;

[0063]Glucose powder 5.0%;

[0064] Emulsified oil powder 2.0%;

[0065] 4% compound premix feed 4.0%.

[0066] All the above-mentioned raw materials can be purchased in the raw material market.

[0067] Second, the operation process steps are as follows:

[0068] (1) Preparation of granulation liquid: the above mass ratio of maltodextrin, soybean protein concentrate powder, plasma protein powder, soluble intestinal membrane protein powder, low ash sweet whey powder, glucose, fully soluble super fish paste protein powder, put it in a plastic container, add an appropriate amount of water, and stir at room temperature until completely dissolved;

[0069...

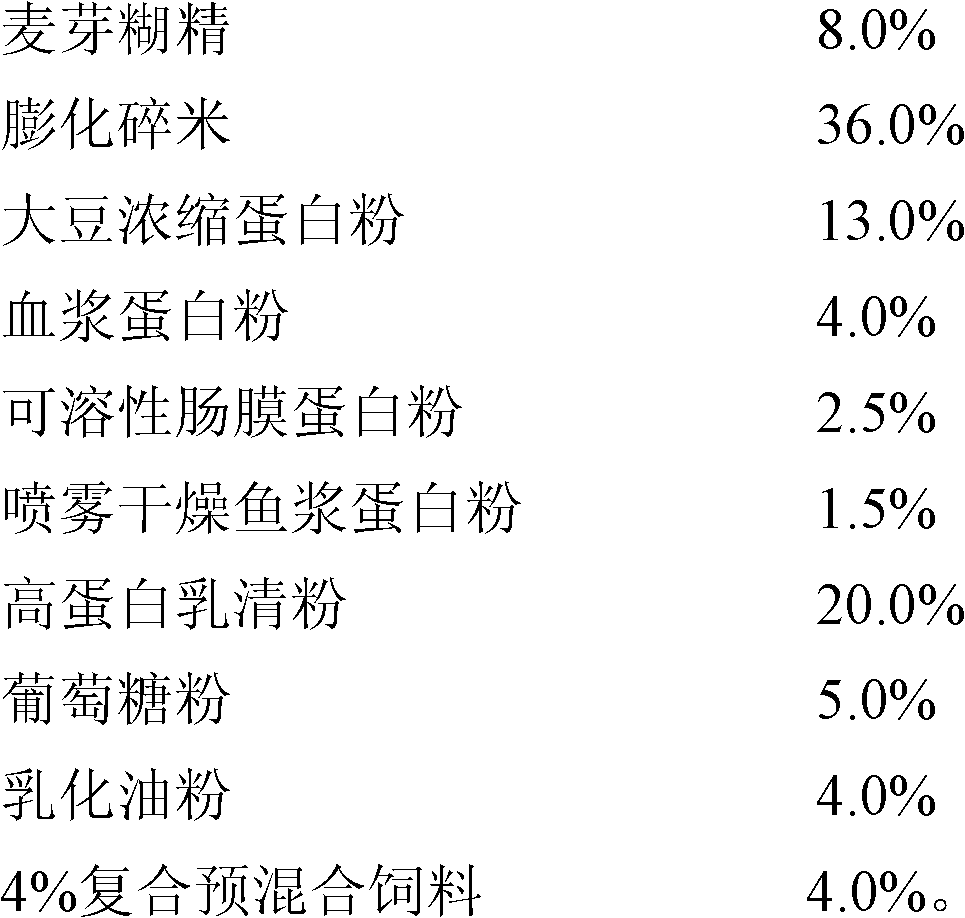

Embodiment 2

[0075] 1. Formula:

[0076]

[0077] All the above-mentioned raw materials can be purchased in the raw material market.

[0078] Second, the operation process steps are as follows:

[0079] (1) Preparation of granulation liquid: the above mass ratio of maltodextrin, soybean protein concentrate powder, plasma protein powder, soluble intestinal membrane protein powder, low ash sweet whey powder, glucose, fully soluble super fish paste protein powder, put it in a plastic container, add an appropriate amount of water, and stir at room temperature until completely dissolved;

[0080] (2) Mixing of raw materials: Pour the remaining raw materials in the mass proportion into a twin-shaft paddle mixer and mix evenly;

[0081] (3) Granulation: Put the mixed raw materials into the swirling fluidized bed, add the above-mentioned granulation liquid, and in the state of continuous stirring, enter the mixed raw material bed by top spraying for granulation. The air flow temperature durin...

Embodiment 3

[0086] 1. Formula:

[0087] Maltodextrin 9.0%;

[0088] Puffed broken rice 34.0%;

[0089] Soy protein concentrate powder 15.0%;

[0090] Plasma protein powder 4.0%;

[0091] Soluble intestinal membrane protein powder 2.0%;

[0092] Spray dried fish paste protein powder 4.5%;

[0093] High Protein Whey Powder 20.0%;

[0094] Glucose powder 5.0%;

[0095] Emulsified oil powder 2.5%;

[0096] 4% compound premix feed 4.0%.

[0097] All the above-mentioned raw materials can be purchased in the raw material market.

[0098] Second, the operation process steps are as follows:

[0099] (1) Preparation of granulation liquid: the above mass ratio of maltodextrin, soybean protein concentrate powder, plasma protein powder, soluble intestinal membrane protein powder, low ash sweet whey powder, glucose, fully soluble super fish paste protein powder, put it in a plastic container, add an appropriate amount of water, and stir at room temperature until completely dissolved;

[0100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com