Dry-steaming method for fine dried noodles and dry-steamed fine dried noodles

A dry steaming technology for dried noodles, which is applied in the dry steaming method of dried noodles and the field of dry steamed noodles, which can solve the problems of general taste, intolerance to storage, and easy to grow insects, etc., and achieve the effects of scientific and reasonable methods, improved shelf life, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dried noodle production: it includes preparing dried noodle from raw materials through batching, kneading, aging, sheeting, strip cutting and drying.

[0022] The raw material of the dried noodles in the present invention is wheat flour or the compound powder of wheat flour and fruits and vegetables grains, and this embodiment is wheat flour.

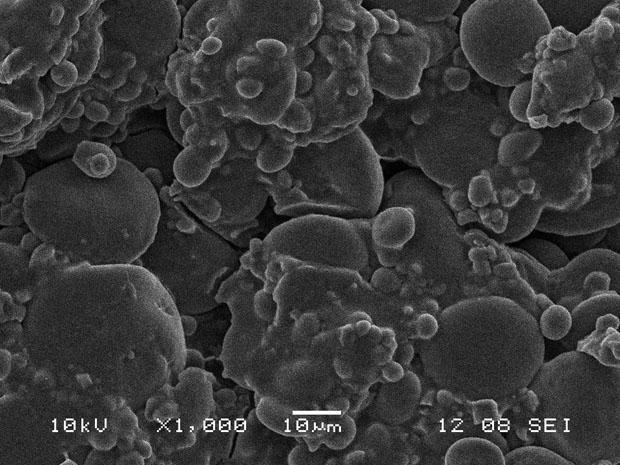

[0023] Depend on figure 2 It can be seen that although ordinary dried noodles have undergone the processes of rolling, curing and drying, due to the limitation of the amount of water added to the dough, the arrangement of the gluten network structure is not very uniform, the gaps between the tissues are large and not tight, and the starch granules on the fascia The distribution is also uneven.

[0024] A kind of dry steaming method of dried noodles, it comprises the following steps:

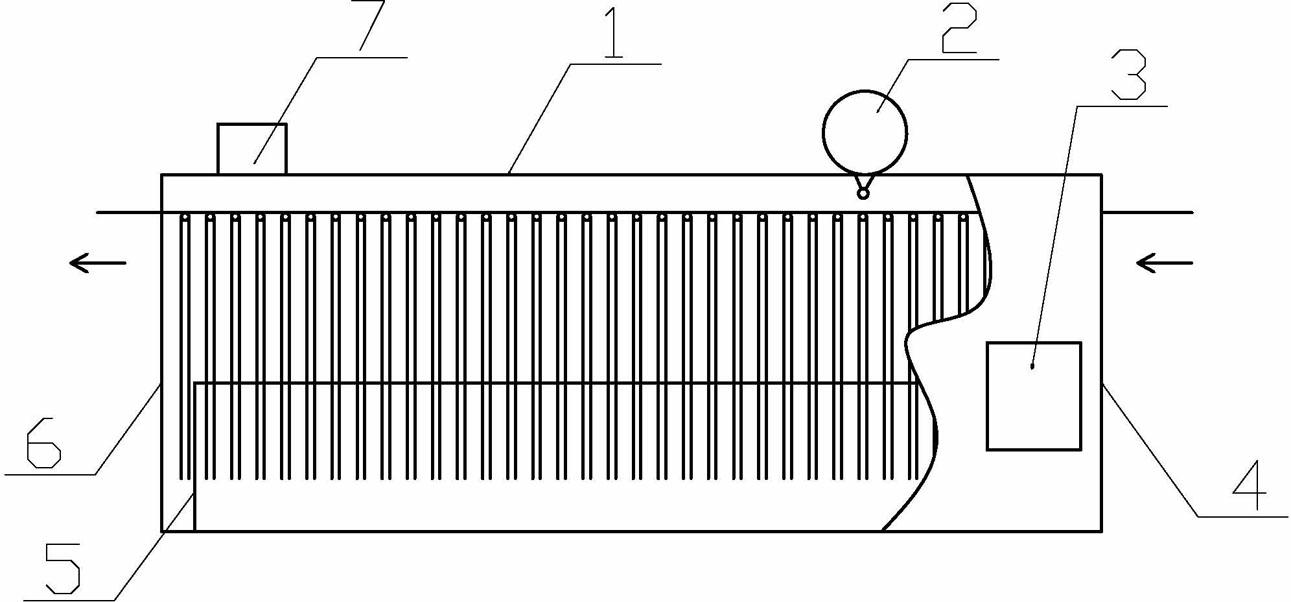

[0025] ⑴Dry steaming: Put the processed vermicelli into the dry steaming device, heat the air in the dry steaming device to 50℃~90℃, and keep it...

Embodiment 2

[0039] The raw material of the dried noodles in the present invention is the compound powder of wheat flour and fruit and vegetable miscellaneous grains, wherein the proportion of wheat flour is 92%, and the proportion of fruit and vegetable miscellaneous grains (sorghum flour is 8%).

[0040] In step (1) of the present invention, the temperature is raised to 70° C. and kept for 24 hours, and the relative humidity is kept at 75%.

[0041] After dry-steaming dried noodles, the moisture content of dried noodles was 12.0%, and the load at the maximum load in the texture index increased by 79.5% compared with the control; the cooking loss rate decreased by 1.1 percentage points compared with the control. The rest are the same as embodiment 1.

Embodiment 3

[0043] The raw material of the dried noodles in the present invention is the compound powder of wheat flour and fruit and vegetable miscellaneous grains, wherein the wheat flour is 95%, the vegetable powder is 2%, and the soybean powder is 3%.

[0044] In step (1) of the present invention, the temperature is raised to 75°C and kept for 6.5 hours, and the relative humidity is kept at 78%.

[0045] After the dry steaming is completed, the dried noodles are cooled to room temperature. The cooling rate in this embodiment is 25°C / hour, and the relative humidity is kept at 75%.

[0046] After dry-steaming dried noodles, the moisture content of dried noodles was 12%, and the load at the maximum load in the texture index increased by 34.9% compared with the control; the cooking loss rate decreased by 0.5 percentage points compared with the control. The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com