Method for preparing copper radiating fins of gradient structures by means of injection forming

A technology of injection molding and gradient structure, which is applied in the field of powder metallurgy, can solve the problems that copper heat sinks do not fully exert their heat absorption capacity, the quality of copper heat sinks limits the application, and the production process is long, so as to increase the specific surface area of heat dissipation and solve the problem of heat dissipation. The effect of preventing problems and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

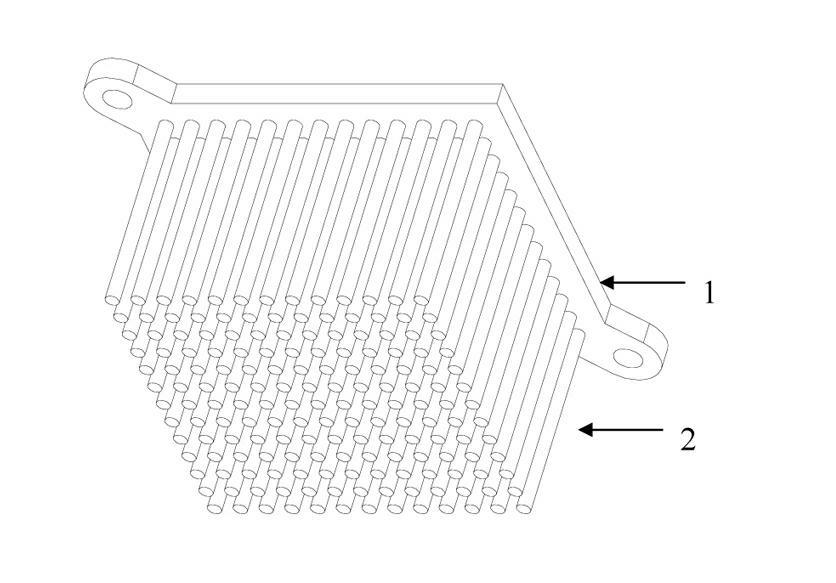

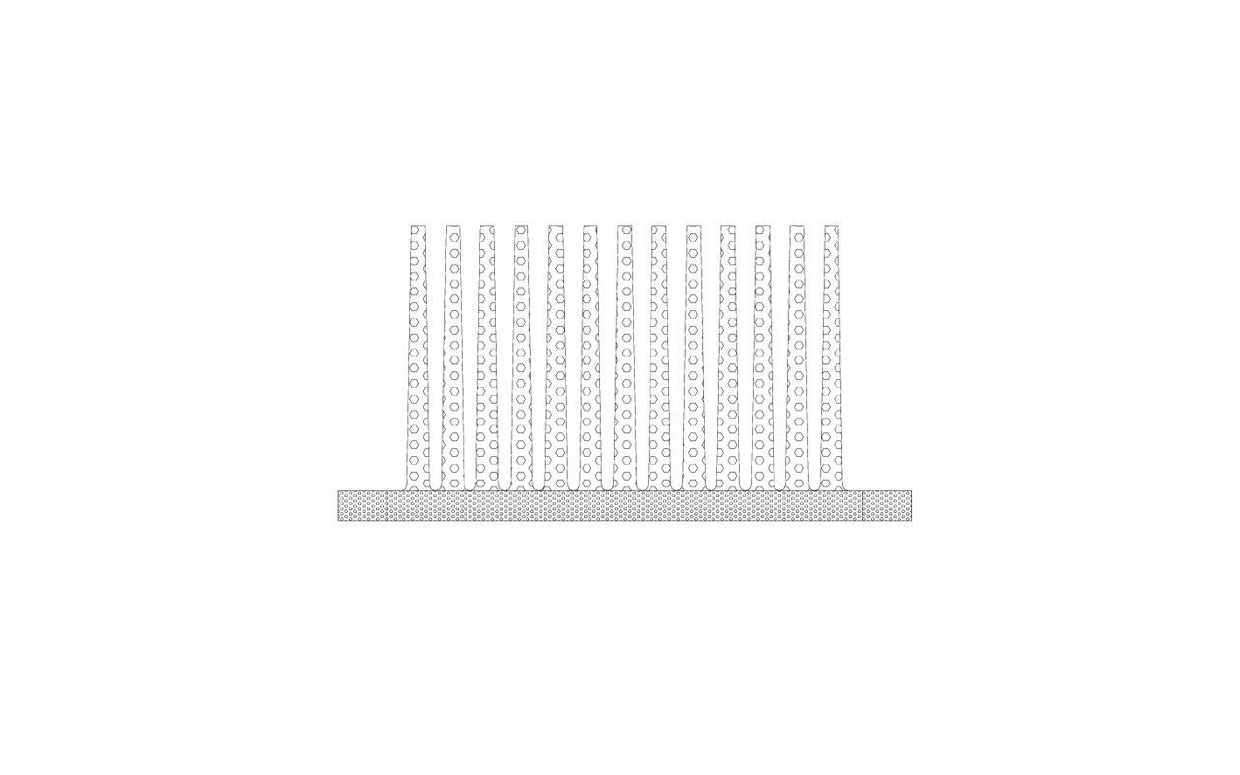

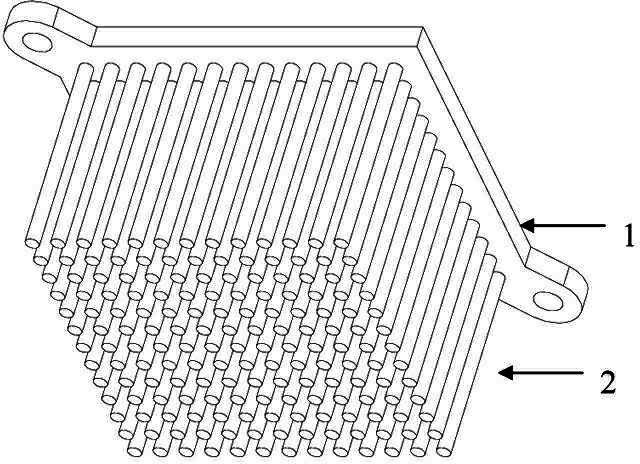

[0043]A method of injection molding to prepare copper heat sink with gradient structure, the structure of cylindrical fin heat sink is as follows figure 1 As shown, 1 is the base of the cylindrical fin heat sink, and 2 is the fin of the cylindrical fin heat sink. by figure 1 The heat sink is shown as an example. The gradient structure copper heat sink includes the fin 2 of the heat sink and the base 1 of the heat sink. The preparation process of the heat sink is as follows:

[0044] ⑴The entire heat sink is prepared by metal powder injection molding technology.

[0045] ① The mass fraction of copper powder for fins is: 5% for +80 mesh, 90% for -80 mesh to +100 mesh, and the balance for -100 mesh. The mass fraction of copper powder for base is: -325 mesh to + 400 mesh is 100%, respectively mixed in a double cone mixer for 12 hours. The volume ratio of the two kinds of copper powder to the binder is 55%: 45%, and the binder composition is 70% of paraffin wax, 5% of high-densi...

Embodiment 2

[0052] A method of injection molding to prepare copper heat sink with gradient structure, the structure of cylindrical fin heat sink is as follows figure 1 As shown, the gradient structure copper heat sink includes the fin 2 of the heat sink and the base 1 of the heat sink, and the preparation process of the heat sink is as follows:

[0053] ⑴The entire heat sink is prepared by metal powder injection molding technology.

[0054] ① The mass fraction of copper powder for fins is: 2% for +80 mesh, 95% for -80 mesh to +100 mesh, and the balance for -100 mesh. The mass fraction of copper powder for base is: +325 mesh is 2% %, -325 mesh to +400 mesh is 95%, and -400 mesh is the balance, respectively mixed in a double-cone mixer for 10 hours. The volume ratio of the two kinds of copper powder to the binder is 60%: 40%, and the binder composition is 65% of paraffin wax, 10% of high-density polyethylene, and 20% of polyethylene acetate-ethyl copolymer. %, 5% stearic acid, mix copper ...

Embodiment 3

[0061] A method of injection molding to prepare copper heat sink with gradient structure, the structure of cylindrical fin heat sink is as follows figure 1 As shown, the gradient structure copper heat sink includes the fin 2 of the heat sink and the base 1 of the heat sink, and the preparation process of the heat sink is as follows:

[0062] ⑴The entire heat sink is prepared by metal powder injection molding technology.

[0063] ① The mass fraction of copper powder for fins is: -80 mesh to +100 mesh is 100%, the mass fraction of copper powder for base is: +325 mesh is 5%, -325 mesh to +400 mesh is 90%, - 400 mesh is the remainder, and they are mixed in a double-cone mixer for 10 hours. The volume ratio of the two kinds of copper powder to the binder is 65%: 35%, and the binder composition is 60% of paraffin wax, 10% of high-density polyethylene, and 25% of polyethylene acetate-ethyl copolymer. %, 5% stearic acid, mix copper powder and binder on a high-speed mixer at 90°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com