Method for reductive decomposition of phosphogypsum with hydrogen gas

A technology of phosphogypsum and hydrogen, applied in chemical instruments and methods, calcium/strontium/barium oxides/hydroxides, inorganic chemistry, etc., can solve unseen problems, reduce process energy consumption, and reduce production costs , the effect of not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

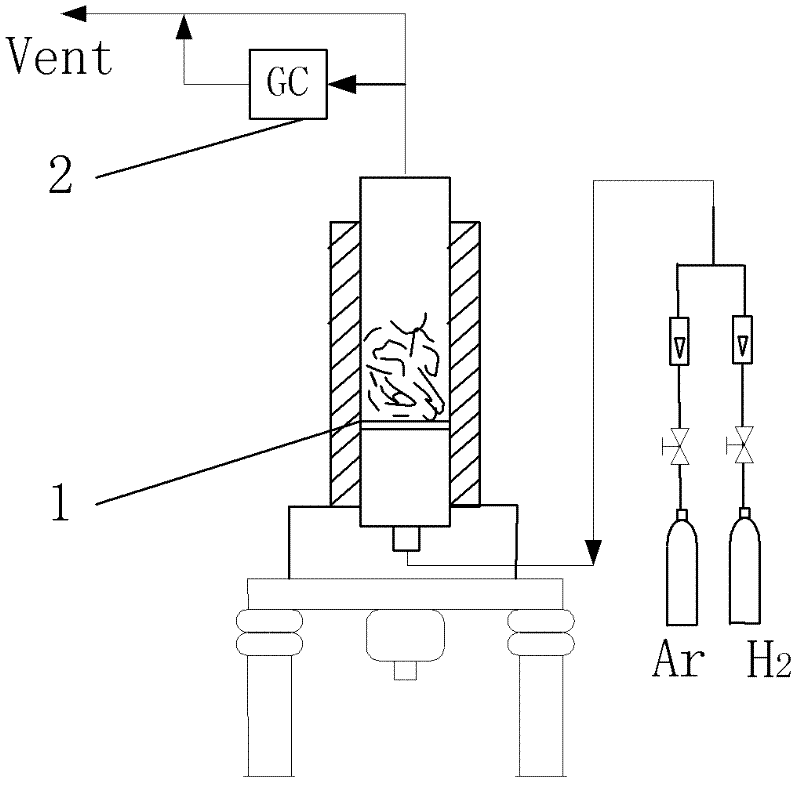

Image

Examples

Embodiment 1

[0026] A method for hydrogen reduction and decomposition of phosphogypsum, which comprises the steps:

[0027] 1) Raw material pretreatment: the raw material is phosphogypsum, the crystal water content of the phosphogypsum raw material is 19.02-23.49% (wet basis), the attached water content is 0.0099-0.167% (wet basis), and the particle size of the phosphogypsum is D 50 =13.57μm;

[0028] Bake the phosphogypsum raw material at a temperature of 600-650° C. for 120-150 minutes (drying) to remove crystal water, cool and crush, and pass through a 200-mesh sieve (Shanghai standard sieve) to obtain pretreated phosphogypsum for use;

[0029] 2) get 189g of pretreated phosphogypsum, press the mass ratio of pretreated phosphogypsum: additive A: additive B=87:12:1, choose pretreated phosphogypsum, additive A and additive B, mix , get the mixture;

[0030] The composition and mass percent of the additive A are: SiO 2 71%, Al2 O 3 16%, Fe 2 O 3 6%, CaO2%, MgO5%;

[0031] The compos...

Embodiment 2

[0034] A method for hydrogen reduction and decomposition of phosphogypsum, which comprises the steps:

[0035] 1) Raw material pretreatment: the raw material is phosphogypsum, the crystal water content of the phosphogypsum raw material is 19.02-23.49% (wet basis), the attached water content is 0.0099-0.167% (wet basis), and the particle size of the phosphogypsum is D 50 =13.57μm;

[0036] Bake the phosphogypsum raw material at a temperature of 600-650° C. for 120-150 minutes (drying) to remove crystal water, cool and crush, and pass through a 200-mesh sieve (Shanghai standard sieve) to obtain pretreated phosphogypsum for use;

[0037] 2) get 95g of pretreated phosphogypsum, press the mass ratio of pretreated phosphogypsum: additive A: additive B=87:12:1, choose pretreated phosphogypsum, additive A and additive B, mix , get the mixture;

[0038] The composition and mass percent of the additive A are: SiO 2 71%, Al 2 O 3 16%, Fe 2 O 3 6%, CaO2%, MgO5%;

[0039] The compo...

Embodiment 3

[0042] A method for hydrogen reduction and decomposition of phosphogypsum, which comprises the steps:

[0043] 1) Raw material pretreatment: the raw material is phosphogypsum, the crystal water content of the phosphogypsum raw material is 19.02-23.49% (wet basis), the attached water content is 0.0099-0.167% (wet basis), and the particle size of the phosphogypsum is D 50 =13.57μm;

[0044] Bake the phosphogypsum raw material at a temperature of 600-650° C. for 120-150 minutes (drying) to remove crystal water, cool and crush, and pass through a 200-mesh sieve (Shanghai standard sieve) to obtain pretreated phosphogypsum for use;

[0045] 2) get 48g of pretreated phosphogypsum, press the mass ratio of pretreated phosphogypsum: additive A: additive B=88:11:1, choose pretreated phosphogypsum, additive A and additive B, mix , get the mixture;

[0046] The composition and mass percent of the additive A are: SiO 2 75%, Al 2 O 3 12%, Fe 2 O 3 7%, CaO2.5%, MgO3.5%;

[0047] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com