Device for absorbing heat energy from combustion of yellow phosphorus with heat transfer oil

A heat-conducting oil and yellow phosphorus technology, applied in phosphoric acid, phosphorus oxyacids, sustainable manufacturing/processing, etc., can solve the problems of phosphorus chemical industry that have not been used in the field of phosphorus, so as to avoid the hidden danger of overpressure, reduce recycling and reuse , the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

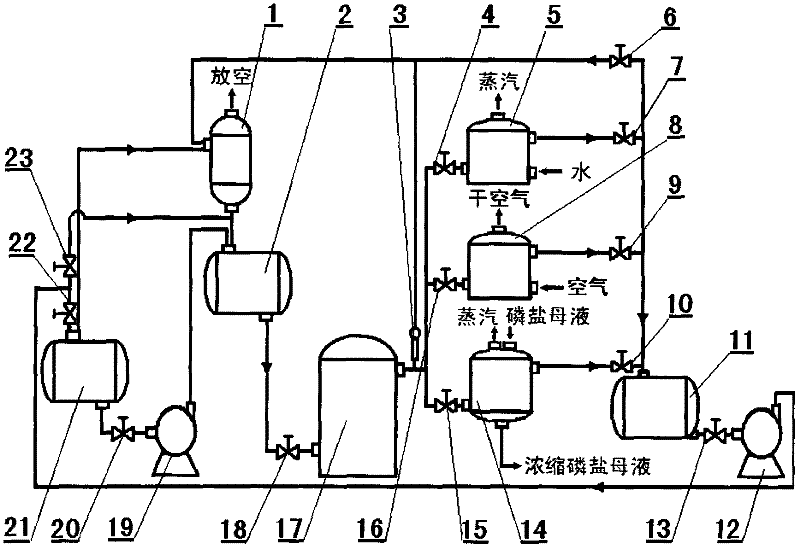

[0025] Embodiment one: the device of concentrating phosphate mother liquor, drying phosphate and preparing steam

[0026] Such as figure 1 , a device for absorbing yellow phosphorus combustion heat by heat-conducting oil, using the jacket of the yellow phosphorus combustion furnace 17 in the phosphoric acid workshop, and adopting stainless steel pipes, valve IX18, oil tank I2, and buffer tank at the jacket oil inlet of the yellow phosphorus combustion furnace 17 1 connected in sequence; the oil inlet of oil tank I2 is connected with the oil inlet of circulating pump II19, valve X20, oil tank III21, valve XI22, valve XII23 and oil tank I2 in sequence with stainless steel pipes. The oil inlets of steam generator 5, air heater 8 and evaporator 14 are connected with the jacket oil outlet of yellow phosphorus burner 17 through valve I4, valve VIII16 and valve VII15 respectively, and the outlet of yellow phosphorus burner 17 is connected by stainless steel pipe. The oil outlet of t...

Embodiment 2

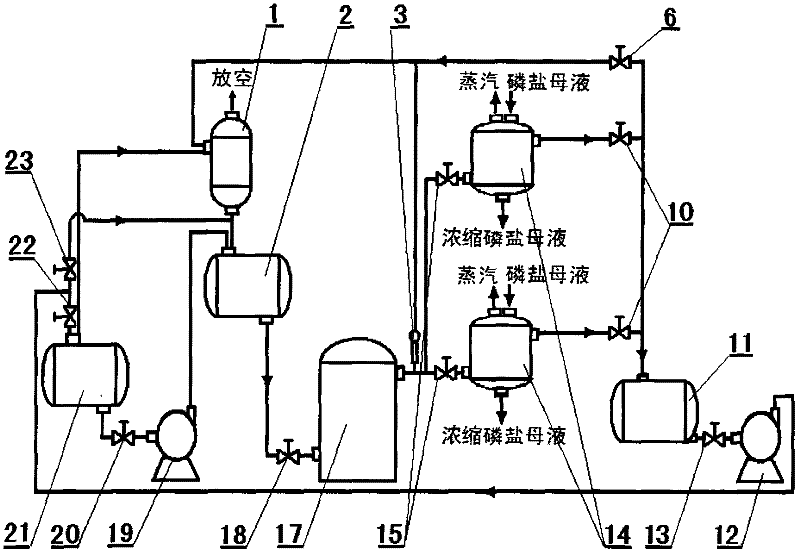

[0028] Embodiment two: the device of concentrated phosphate mother liquor

[0029] Utilize the jacket of yellow phosphorus combustion furnace 17 in phosphoric acid workshop, adopt seamless steel pipe to connect with valve IX18, oil tank I2, surge tank 1 in sequence at the jacket oil inlet of yellow phosphorus combustion furnace 17; The oil inlet of oil tank I2 is connected with The oil inlets of circulation pump II19, valve X20, oil tank III21, valve XI22, valve XII23 and oil tank I2 are connected in turn by seamless steel tubes. The oil inlets of the two evaporators 14 are respectively connected with the jacket oil outlet of the yellow phosphorus burner 17 through two valves VII15 by seamless steel pipes, and the jacket oil outlet of the yellow phosphorus burner 17 is provided with a safety valve 3 for safety. The valve 3 is connected to the buffer tank 1; the oil outlets of the two evaporators 14 are respectively connected to the oil tank II11 through two valves V10. The oi...

Embodiment 3

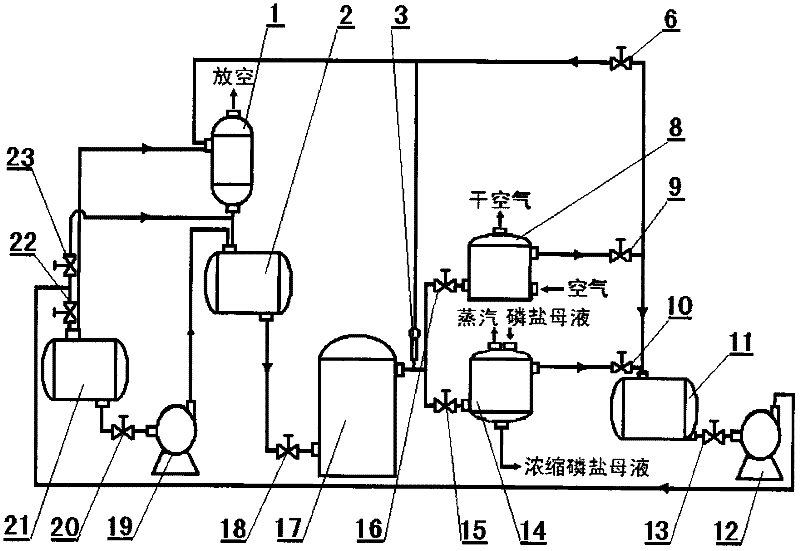

[0031] Embodiment three: the device of concentrating phosphate mother liquor and drying phosphate

[0032] Such as image 3 , a device for heat transfer oil to absorb yellow phosphorus combustion heat, using the jacket of the yellow phosphorus combustion furnace 17 in the phosphoric acid workshop, the jacket oil inlet of the yellow phosphorus combustion furnace 17 adopts seamless steel pipe and valve IX18, oil tank I2, buffer Tank 1 is connected in sequence; the oil inlet of oil tank I2 is connected with the oil inlet of circulating pump II19, valve X20, oil tank III21, valve XI22, valve XII23 and oil tank I2 in sequence with seamless steel tubes. The oil inlets of the air heater 8 and the evaporator 14 are respectively connected to the jacket oil outlet of the yellow phosphorus burner 17 through valves VIII16 and VIII15, and the jacket oil outlet of the yellow phosphorus burner 17 is set to be safe. Valve 3 and safety valve 3 are connected to buffer tank 1; the oil outlets o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com