Preparation method of chlorinated special pentane

A technology of chlorpentane and phosphorus trichloride, which is applied in the field of preparation of chlorpentane, can solve the problems of low production efficiency, large amount of hydrochloric acid added, difficult post-treatment, etc., and achieves shortened reaction time, high content The effect of improving and reducing the difficulty of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0022] Phosphorus trichloride is added to the reaction kettle equipped with 5±2Wt.% hydrochloric acid aqueous solution, and the reaction temperature is controlled at 5°C±2°C to generate hydrogen chloride gas, and the flow rate of hydrogen chloride gas is controlled to be 150m 3 / h, by controlling the gauge pressure -0.005~-0.01MPa, the generated hydrogen chloride gas is introduced into the packed tower. The gas is convected with the pre-cooled isopentene spray liquid, the flow rate of the isopentene spray liquid is 680L / h, the contact reaction time of isopentene and hydrogen chloride gas is 20-30s, and the direct gas-liquid reaction can produce chlorinated Pentane.

[0023] Gauge pressure -0.005~-0.01MPa draws unreacted hydrogen chloride gas, which is absorbed by the hydrochloric acid absorption tower. After absorbing the hydrochloric acid content of 5±2Wt.%, it can be recycled for the reaction raw material.

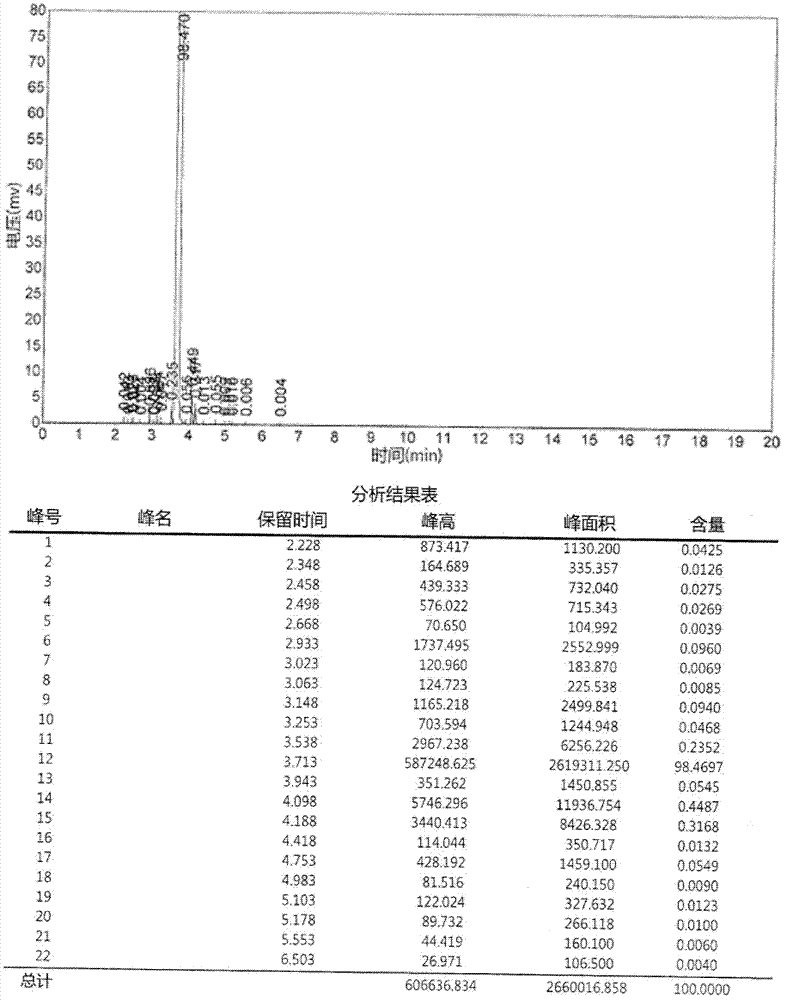

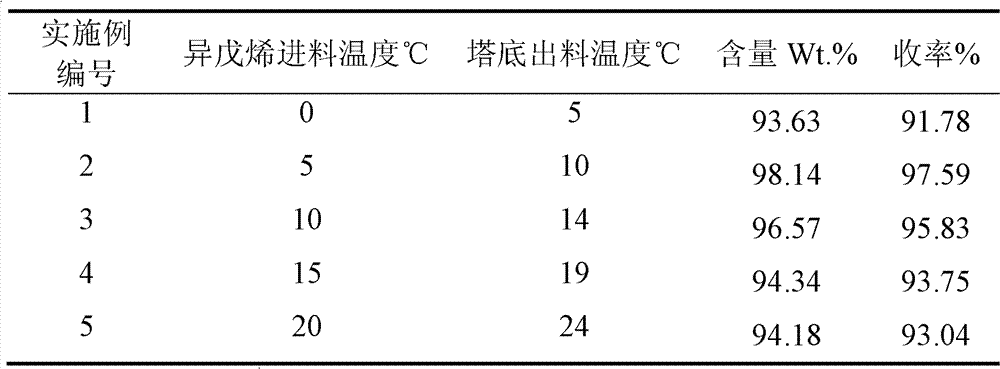

[0024] Table 1: Effect of temperature on product content and yield...

Embodiment 6-10

[0028] Phosphorus trichloride is added in the reactor that is equipped with 5 ± 2Wt.% hydrochloric acid aqueous solution, control reaction temperature 5 ± 2 ℃, generate hydrogen chloride gas, control the flow rate of hydrogen chloride gas, by controlling gauge pressure -0.005~-0.01MPa, will produce The hydrogen chloride gas is introduced into the packed tower. The packed tower body used is 10m high, the packing layer height is 8m, and the tower diameter is 60cm. The contact reaction time between alkenes and hydrogen chloride gas is 20-30s, and the direct gas-liquid reaction can produce chloropentane; during the whole reaction process, the temperature at the bottom of the tower is controlled at 10±2°C.

[0029] Gauge pressure -0.005~-0.01MPa draws unreacted hydrogen chloride gas, which is absorbed by the hydrochloric acid absorption tower. After absorbing the hydrochloric acid content of 5±2Wt.%, it can be recycled for the reaction raw material.

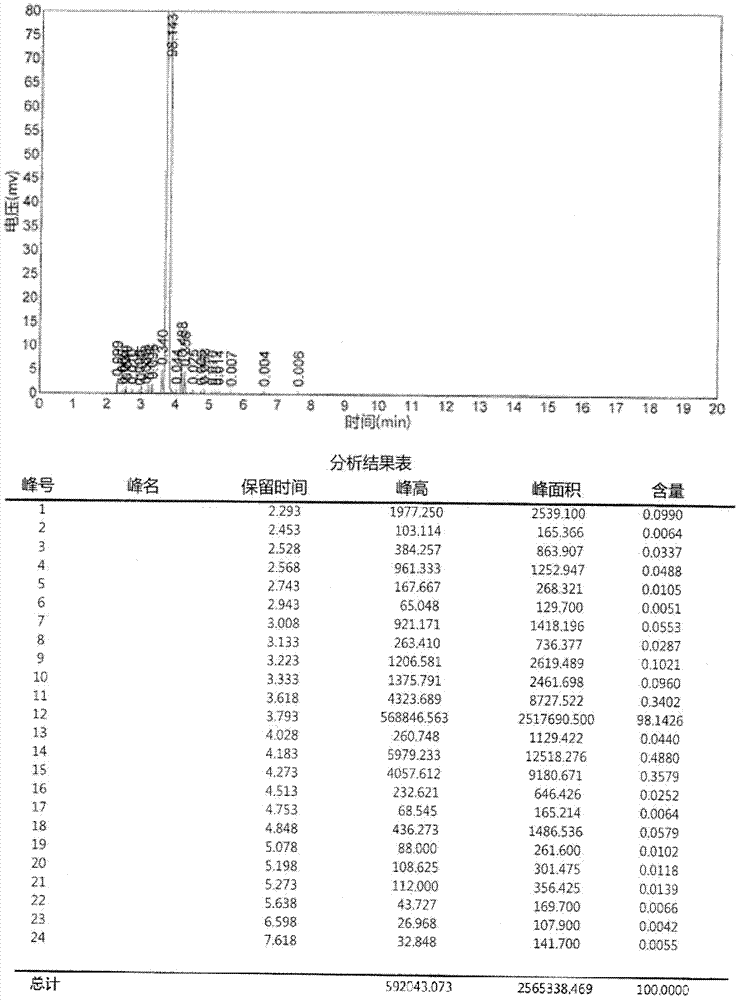

[0030] Table 2: Effects of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com