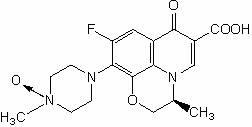

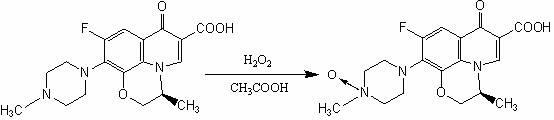

Preparation method of levofloxacin-N-oxide

A levofloxacin and oxide technology is applied in the field of preparation of levofloxacin-N-oxide, which can solve the problems of large amount of hydrogen peroxide, many impurities in the reaction, troublesome post-processing, etc., and achieve the effects of small amount of hydrogen peroxide, simple process, and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 5 grams of levofloxacin and 50 mL of glacial acetic acid into a 100 mL three-necked flask, and raise the temperature to 60-70 °C to completely dissolve the levofloxacin. Add 0.3g of sodium tungstate, 5mL of hydrogen peroxide (30%), keep warm at 60-70°C for 2 hours, then add 5mL of hydrogen peroxide (30%) and continue to keep warm for 3 hours, and the reaction is completed by TLC. Evaporate under reduced pressure until about one-third of the volume of the solution remains, then add some water, continue to evaporate under reduced pressure until about one-third of the remaining volume, repeat this step 3 times, and then evaporate to dryness. The residue was dissolved by adding 55 mL of ethanol (90%) and heated under reflux, then filtered, and the filtrate was cooled and crystallized in the refrigerator, and filtered and dried the next day to obtain 3.5 g of levofloxacin-N-oxide. m / z: 378.1461 (m+H).

Embodiment 2

[0022] Add 5 grams of levofloxacin and 70 mL of glacial acetic acid into a 100 mL three-necked flask, and raise the temperature to 60-70 °C to completely dissolve the levofloxacin. Add 0.3g of phosphotungstic acid, 5mL of hydrogen peroxide (30%), keep the reaction at 60-70°C for 2 hours, then add 5mL of hydrogen peroxide (30%) and continue the reaction for 3 hours, and the reaction is completed by TLC. Evaporate under reduced pressure until about one-third of the volume of the solution remains, then add some water, continue to evaporate under reduced pressure until about one-third of the remaining volume, repeat this step 3 times, and then evaporate to dryness. The residue was dissolved by adding 55 mL of methanol (90%) and heated under reflux, then filtered, and the filtrate was cooled and crystallized in the refrigerator, and filtered and dried the next day to obtain 3.4 g of levofloxacin-N-oxide. m / z: 378.1461 (m+H).

Embodiment 3

[0024] Add 5 grams of levofloxacin and 70 mL of glacial acetic acid into a 100 mL three-necked flask, and raise the temperature to 60-70 °C to completely dissolve the levofloxacin. Add 0.3g of phosphomolybdic acid, 5mL of hydrogen peroxide (30%), keep the reaction at 60-70°C for 2 hours, then add 5mL of hydrogen peroxide (30%) and continue the reaction for 3 hours, and the reaction is completed by TLC. Evaporate under reduced pressure until about one-third of the volume of the solution remains, then add some water, continue to evaporate under reduced pressure until about one-third of the remaining volume, repeat this step 3 times, and then evaporate to dryness. The residue was dissolved by adding 55 mL of ethanol (90%) and heated under reflux, then filtered, and the filtrate was cooled and crystallized in the refrigerator, and filtered and dried the next day to obtain 3.3 g of levofloxacin-N-oxide. m / z: 378.1461 (m+H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com