Substrate water retaining agent and preparation method thereof

A technology of water-retaining agent and matrix, which is applied in the fields of agriculture and forestry. It can solve the problems of slow degradability, poor water-retaining capacity, and high cost of polymer compounds, and achieve the effects of improving physical and chemical properties, long water-retaining time, and moderate pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

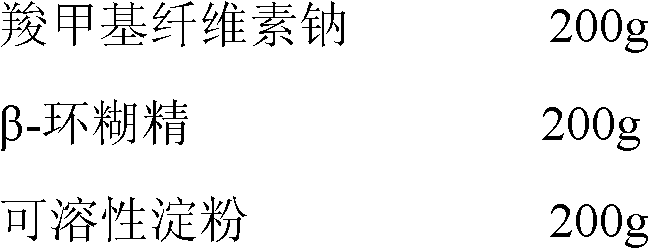

[0058] 1. Prepare raw materials according to the following weight

[0059] Sodium Carboxymethyl Cellulose 200g

[0060] β-cyclodextrin 200g

[0061] Soluble starch 200g

[0062]

[0063] 2. Add the additive soluble starch, binder β-cyclodextrin and sodium carboxymethyl cellulose to 4020 g of water, mix well, and make a pretreatment mixture, wherein the total weight of the additive and the binder is equal to the weight of the water The weight ratio is 1: 6.7, the weight ratio of β-cyclodextrin and carboxymethyl cellulose sodium in the binder is 1: 1, and the ratio of the total weight of additives to the total weight of the binder is 1: 2;

[0064] 3. Heat the uniformly mixed pretreatment mixture and stir evenly. The heating temperature is 60°C and heat treatment for 15 minutes, so that sodium carboxymethylcellulose and β-cyclodextrin are dispersed in water, and the soluble starch is completely gelatinized. form a colloidal mixture;

[0065] 4. Put the colloidal mixture i...

Embodiment 2

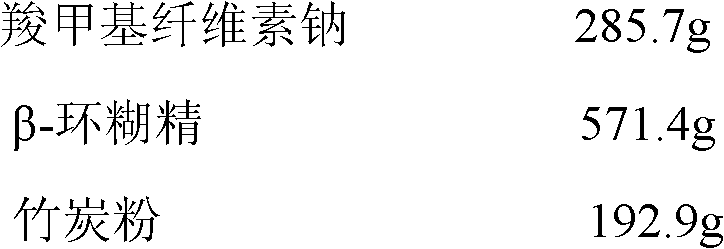

[0067] 1. Prepare raw materials according to the following weight:

[0068] Sodium Carboxymethyl Cellulose 285.7g

[0069] β-cyclodextrin 571.4g

[0070] Bamboo Charcoal Powder 192.9g

[0071]

[0072] Among them, the particle size of bamboo charcoal powder is 0.25-0.5mm;

[0073] 2. Add the additive bamboo charcoal powder and the binder β-cyclodextrin and sodium carboxymethylcellulose into water with a weight of 1700g, mix well, and make a pretreatment mixture, wherein the total weight of the additive and the binder is equal to that of the water The weight ratio is 1: 1.6, the weight ratio of β-cyclodextrin and carboxymethyl cellulose sodium in the binder is 2: 1; the ratio of the total weight of additives to the total weight of the binder is 1: 4.4;

[0074] 3. Heat the uniformly mixed pretreatment mixture and stir evenly. The heating temperature is 65°C and heat treatment for 10 minutes to disperse sodium carboxymethyl cellulose, β-cyclodextrin and bamboo charcoal pow...

Embodiment 3

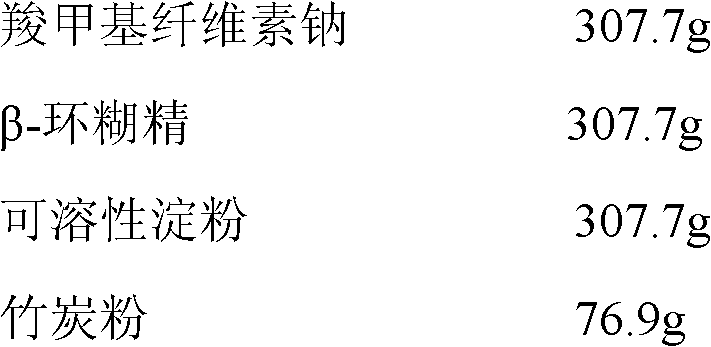

[0077] 1. Prepare raw materials according to the following weight:

[0078]

[0079] Among them, the particle size of bamboo charcoal powder is less than 0.25mm.

[0080] 2. Add additives soluble starch, bamboo charcoal powder, binders β-cyclodextrin and sodium carboxymethyl cellulose to water with a weight of 1200g, mix well, and make a pretreatment mixture, wherein the total weight of additives and binders The weight ratio with water is 1:12, the weight ratio of β-cyclodextrin and sodium carboxymethyl cellulose in the binder is 1:1; the ratio of the total weight of additives to the total weight of binder is 1: 1.6;

[0081] 3. Heat the uniformly mixed pretreatment mixture and stir evenly. The heating temperature is 65°C, heat treatment for 20 minutes, disperse sodium carboxymethylcellulose, β-cyclodextrin, and bamboo charcoal powder in water, and soluble starch paste Completely melted to form a colloidal mixture;

[0082] 4. Put the colloidal mixture in an oven for dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com