Protective coating and preparation method thereof

A technology of protective coatings and epoxy resins, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of destroying the paint film of anti-graffiti and anti-sticking coatings, high cost, etc., and achieve the effect of low cost, simple processing and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiments of the present invention provide a protective coating and a preparation method thereof, the protective coating is a transparent coating with anti-sticking and anti-graffiti functions.

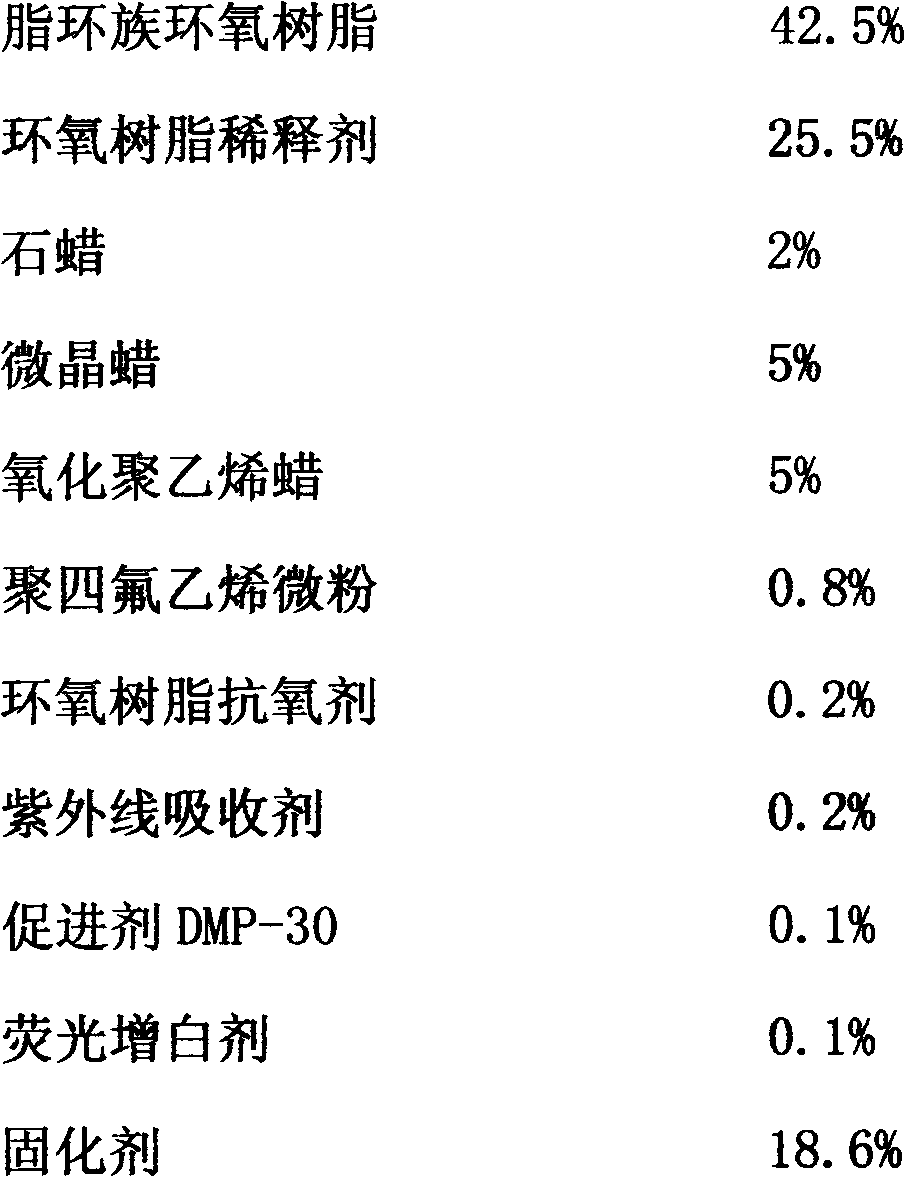

[0053] The protective paint comprises the following components by weight percentage:

[0054]

[0055] Preferably, the epoxy resin diluent can use a reactive diluent, such as one or more of C12-14 fatty glycidyl ether, D-691 propylene oxide o-cresyl ether or o-cresyl glycidyl ether .

[0056] Preferably, the epoxy resin antioxidant can be compounded with epoxy anti-yellowing agent V78-P, epoxy anti-yellowing agent V85-P, and antioxidant 235.

[0057] Preferably, the curing agent can be HB-8138, which is a modified alicyclic amine epoxy curing agent. It has low viscosity, high reactivity, light color, fast curing, good surface effect, good weather resistance, excellent oxidation resistance and light and heat stability.

[0058] The preparation method of the above-mention...

Embodiment 2

[0060] Embodiments of the present invention provide a protective coating and a preparation method thereof, wherein the protective coating is a white coating with anti-sticking and anti-graffiti functions.

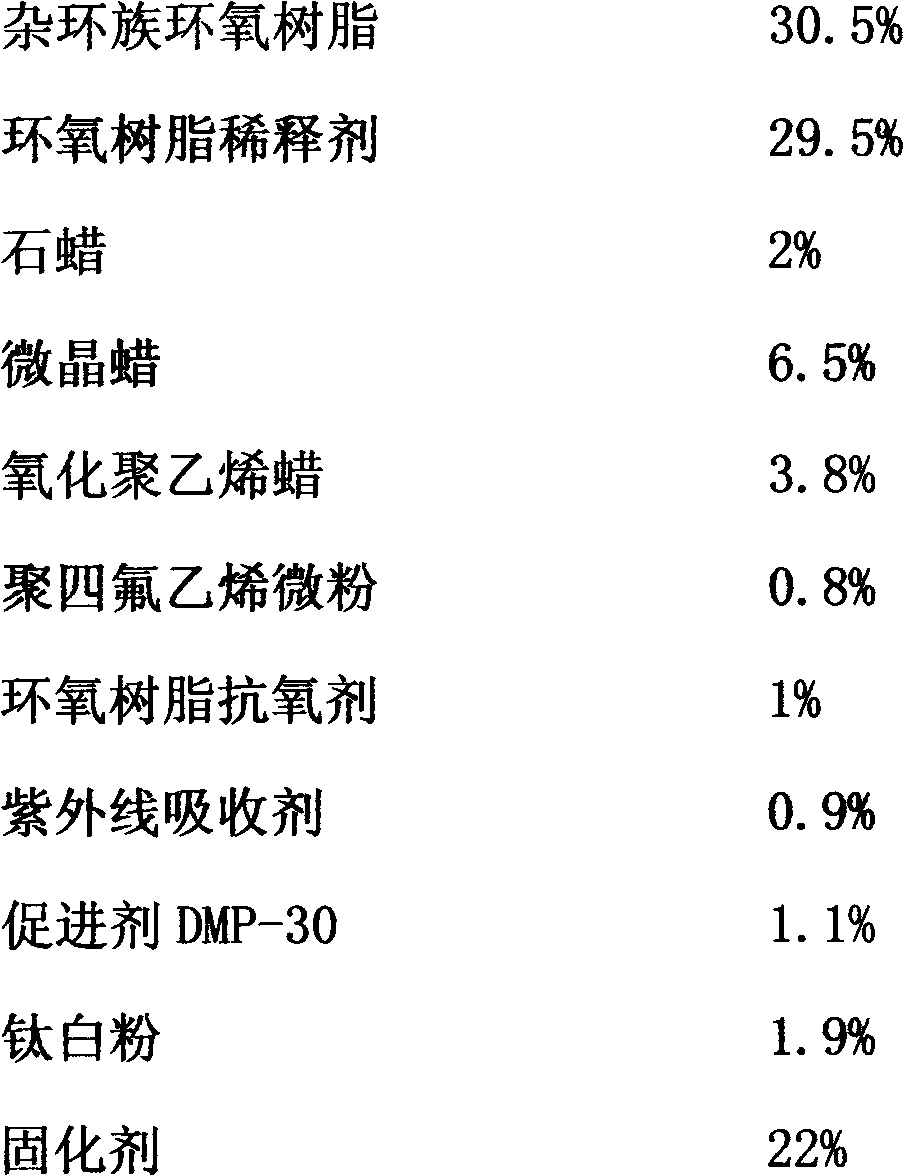

[0061] The protective paint comprises the following components by weight percentage:

[0062]

[0063] Preferably, the epoxy resin diluent can use a reactive diluent, such as one or more of C12-14 fatty glycidyl ether, D-691 propylene oxide o-cresyl ether or o-cresyl glycidyl ether .

[0064] Preferably, the epoxy resin antioxidant can use one or more of epoxy anti-yellowing agent V78-P, epoxy anti-yellowing agent V85-P, antioxidant 235, and the use of titanium dioxide can be Reduce the amount of anti-yellowing agent used.

[0065] Preferably, the curing agent can be HB-8138, which is a modified alicyclic amine epoxy curing agent. It has low viscosity, high reactivity, light color, fast curing, good surface effect, good weather resistance, excellent oxidation resistan...

Embodiment 3

[0069] Embodiments of the present invention provide a protective paint and a preparation method thereof. The protective paint is a light gray paint with anti-sticking and anti-graffiti functions.

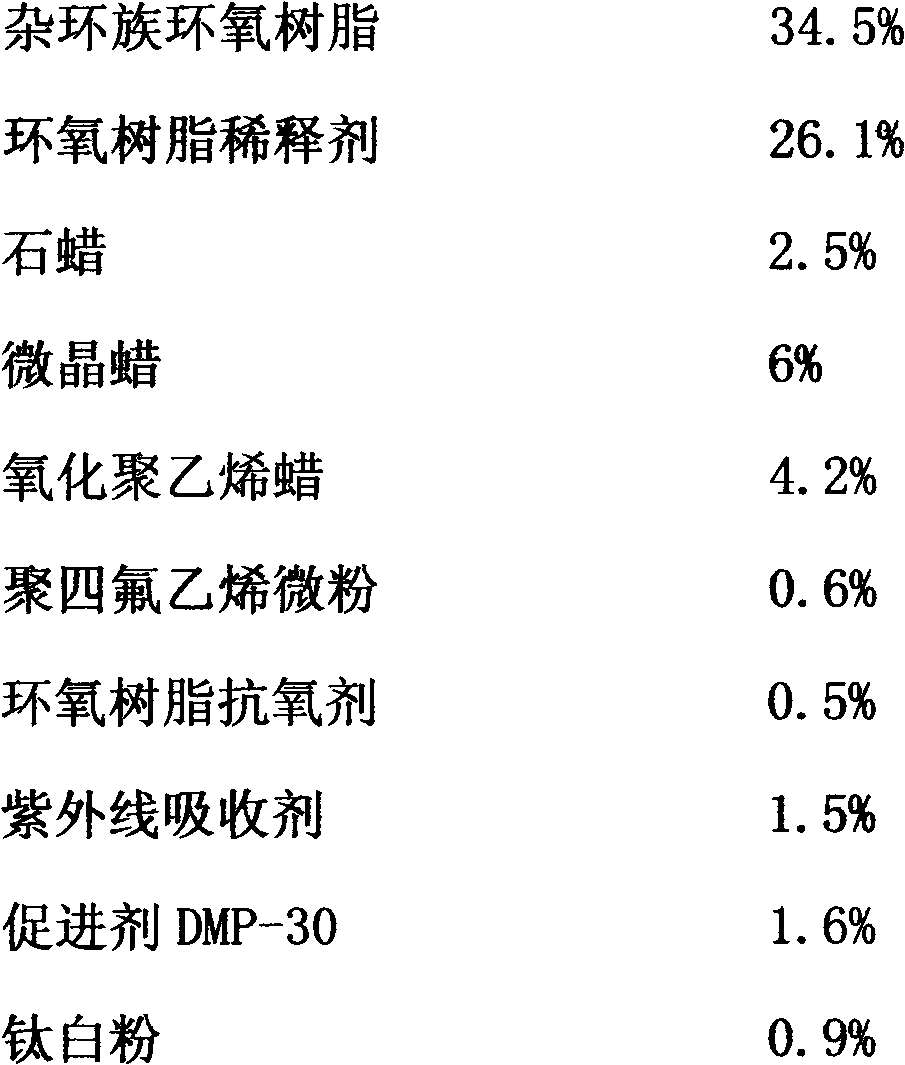

[0070] The protective paint comprises the following components by weight percentage:

[0071]

[0072]

[0073] Preferably, the epoxy resin diluent can use a reactive diluent, such as one or more of C12-14 fatty glycidyl ether, D-691 propylene oxide o-cresyl ether or o-cresyl glycidyl ether .

[0074] Preferably, the epoxy resin antioxidant can be compounded with epoxy anti-yellowing agent V78-P, epoxy anti-yellowing agent V85-P, and antioxidant 235.

[0075] Preferably, the curing agent can be HB-8138, which is a modified alicyclic amine epoxy curing agent. It has low viscosity, high reactivity, light color, fast curing, good surface effect, good weather resistance, excellent oxidation resistance and light and heat stability.

[0076] Preferably, the titanium dioxide can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com