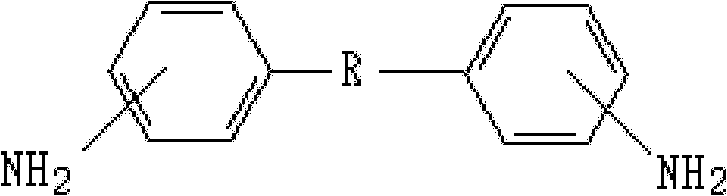

Polyamide hot melt adhesive and application thereof

A polyamide hot-melt adhesive and diamine technology, applied in adhesives, other chemical processes, chemical instruments and methods, etc., can solve the problem of low viscosity, achieve low water absorption, facilitate industrial production, oil resistance and chemical resistance high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

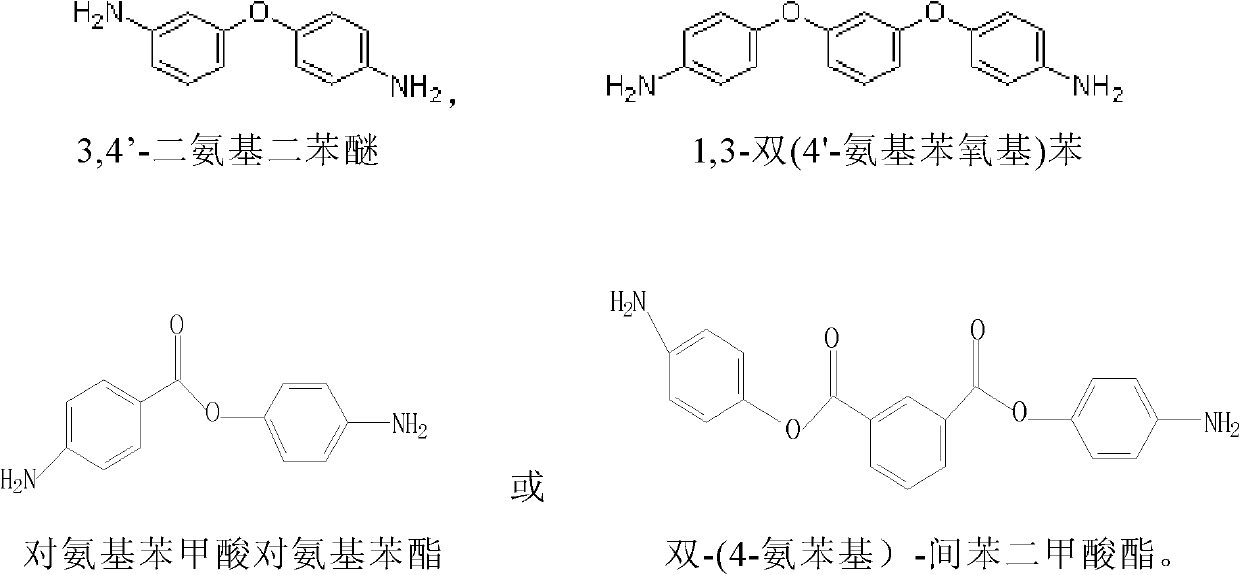

Method used

Image

Examples

Embodiment 1

[0066] With 0.82mol dimer acid (purchased from British Woda Company, Pripol 1013, dimer acid content 95%), 0.15mol sebacic acid, 0.2mol 3,4'-diaminodiphenyl ether (purchased from Jinrui Co., Ltd. ), 0.03mol stearic acid and 1.2g antioxidant 1010 were put into a 1000ml three-necked flask, and the temperature was raised slowly under nitrogen protection until the sebacic acid in the bottle was completely dissolved, and the temperature was kept at 130-140°C. 0.80mol ethylenediamine was dropped into the reaction flask at this temperature. Generally, the dripping is finished within 30 minutes. During the dropping, the temperature in the reaction bottle should preferably be kept below 140°C. If it exceeds 140°C, the dropping speed can be stopped or slowed down until all the dropping is finished; add 10 drops of phosphoric acid. Slowly increase the reaction temperature at a heating rate of 20°C / hour until it rises to 230-240°C, keep this temperature for at least 1 hour, and measure th...

Embodiment 2~8

[0069] According to the formula in Table 1, with reference to the process of Example 1, polyamide hot-melt adhesive particles were prepared, and various properties of the obtained polyamide hot-melt adhesive were tested according to the above-mentioned test method.

[0070] The performance comparison is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Global softening point | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com