Yttrium silicate hot-spray composite powder and preparation method thereof

A composite powder and thermal spraying technology, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problem that the anti-high temperature oxidation coating cannot meet the use requirements, and achieve excellent high temperature oxidation resistance and low thermal conductivity The effect of high efficiency and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of yttrium silicate thermal spraying composite powder of the present invention comprises the following steps:

[0017] Step 1: SiO 2 and Y 2 o 3 The powder is uniformly mixed in the mixer for 20-24h.

[0018] Step 2: Prepress the mixed powder prepared in Step 1 under 600-800kPa.

[0019] Step 3: Sinter the powder prepared in step 2 in air at 1500-1700° C. for 4-6 hours.

[0020] Step 4: mechanically crushing the sintered body prepared in step 3.

[0021] Step 5: Classify the powder prepared in step 4.

[0022] Step 6: Analyze the phase composition of the powder obtained in Step 5 with an X-ray diffractometer.

[0023] Step 7: Measure the fluidity and bulk density of the powder obtained in step 5.

Embodiment 1

[0025] Step 1: Incorporate 25wt% SiO 2 and 75wt% Y 2 o 3 The powder is uniformly mixed in the mixer for 20h, and the particle size of the raw material is: SiO 2 2 o 3 : <15 μm.

[0026] Step 2: Prepress the mixed powder prepared in Step 1 under 700kPa.

[0027] Step 3: Sinter the powder prepared in step 2 in air at 1600°C for 4 hours.

[0028] Step 4: The sintered body prepared in step 3 is mechanically crushed, and the particle size of the thermal sprayed composite powder is 45-125 μm.

[0029] Step 5: Classify the powder prepared in step 4.

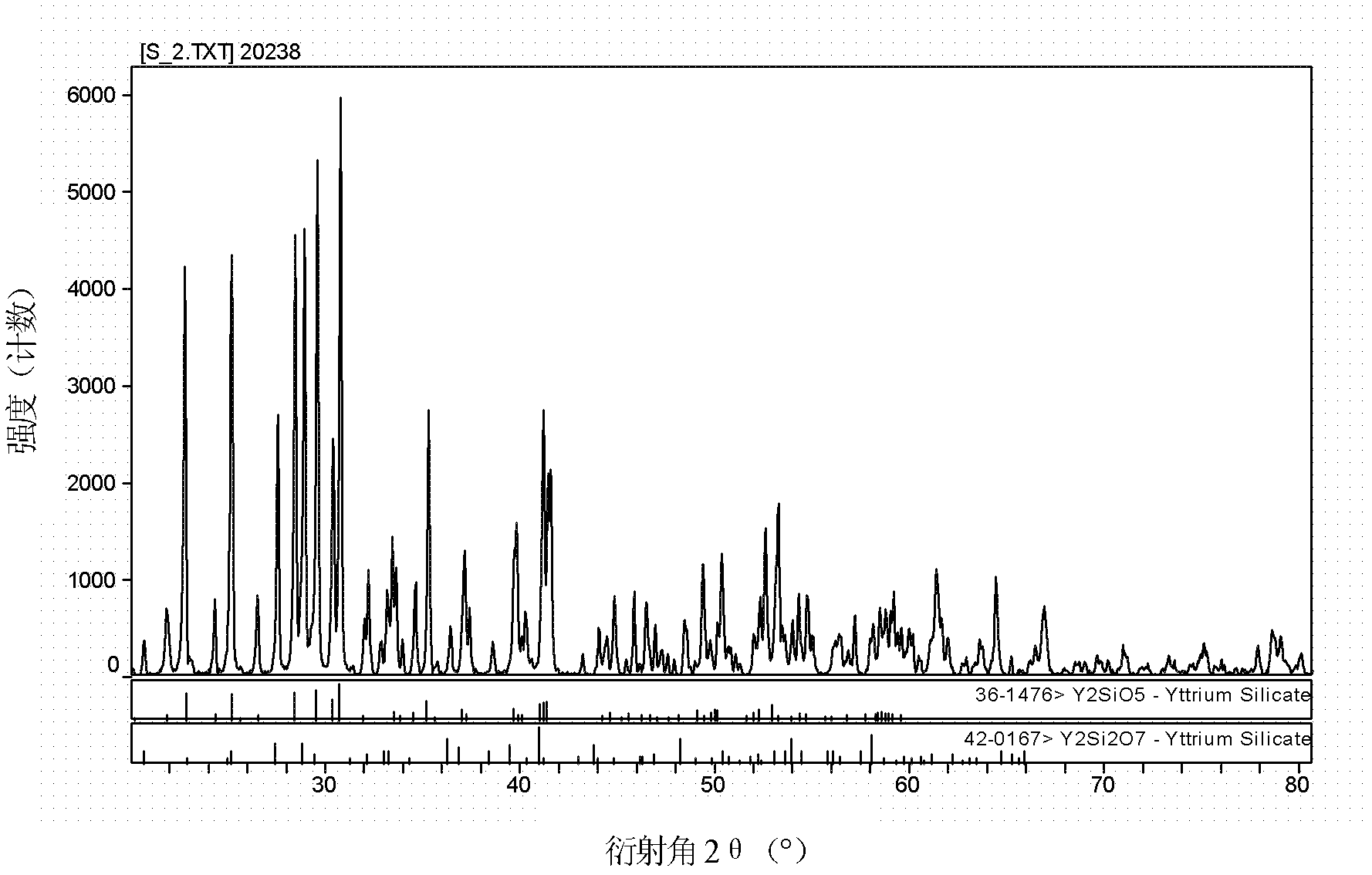

[0030] Step 6: use X-ray diffractometer analysis to obtain the phase composition of powder ( figure 1 ), the powder consists of Y 2 SiO 5 and Y 2 Si 2 o 7 composition. In this example, Y 2 Si 2 o 7 Accounting for 40wt%, Y 2 SiO 5 Accounting for 60wt%.

[0031] Step 7: Measure the fluidity and bulk density of the powder obtained in step 5. The fluidity of the powder is 43s / 50g, and the bulk density is 2.2g / cm 3 .

Embodiment 2

[0036] Step 1: Incorporate 25wt% SiO 2 and 75wt% Y 2 o 3 The powder is mixed in the mixer for 22h, the particle size of the raw material is: SiO 2 2 o 3 : <15 μm.

[0037] Step 2: Prepress the mixed powder prepared in Step 1 under 800kPa.

[0038] Step 3: Sinter the powder prepared in Step 2 in air at 1600°C for 5 hours.

[0039] Step 4: The sintered body prepared in step 3 is mechanically crushed, and the particle size of the thermal sprayed composite powder is 45-125 μm.

[0040] Step 5: Classify the powder prepared in step 4.

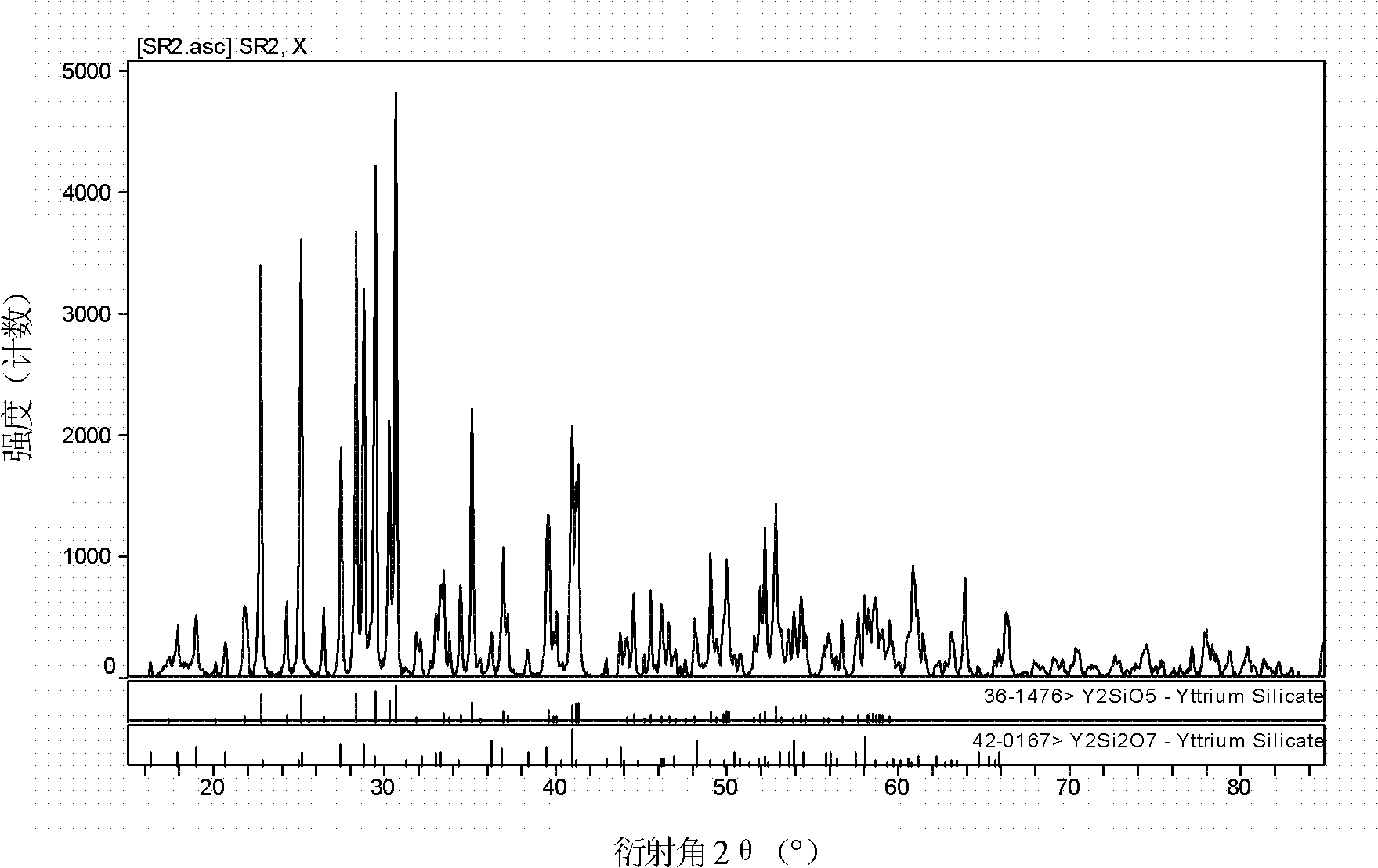

[0041] Step 6: use X-ray diffractometer analysis to obtain the phase composition of powder ( figure 2 ), the powder consists of Y 2 SiO 5 and Y 2 Si 2 o 7 composition. In this example, Y 2 Si 2 o 7 Accounting for 45wt%, Y 2 SiO 5 Accounting for 55 wt%.

[0042]Step 7: Measure the fluidity and bulk density of the powder obtained in step 5. The fluidity of the powder is 45s / 50g, and the bulk density is 2.3g / cm 3 .

[0043] Applica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com