Bamboo-charcoal wet guide type polyester fiber and preparation method and application thereof

A polyester fiber and bamboo charcoal technology, applied in the field of polyester fiber, can solve problems such as spots or fading, odor, human health hazards, etc., to achieve enhanced water absorption and moisture conductivity, increased porosity and surface area, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

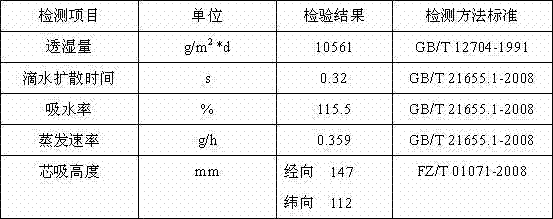

Embodiment 1

[0017] 1, a kind of bamboo charcoal moisture-conducting type polyester fiber, it is made of the raw material of following weight: 20 kilograms of activated carbon masterbatches, 90 kilograms of polyester fiber-forming resins, and described special-shaped section is special-shaped hollow section.

[0018] 2. Preparation of bamboo charcoal moisture-conducting polyester fiber:

[0019] (1) First, the bamboo charcoal is ground into fine powder, and then the bamboo charcoal fine powder is blown with compressed air to enrich the activated carbon particles of 350nm to 500nm, and then 25~35% by weight of activated carbon with a particle size of 350~500nm and 65~ 75% polyethylene terephthalate is blended, extruded with a screw extruder, pelletized, and activated carbon masterbatches are obtained, and the blending temperature is 250~270°C, and the screw speed is 100~ 200rpm;

[0020] (2) Take 20 kilograms of activated carbon master batches obtained in step (1) and blend them with 90 k...

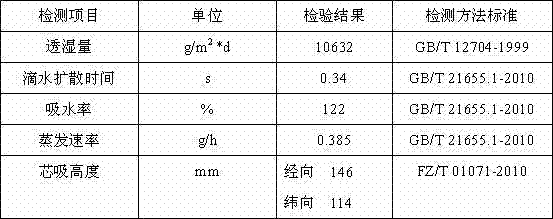

Embodiment 2

[0029] 1, a kind of bamboo charcoal moisture-conducting type polyester fiber, it is made of the raw material of following weight: 10 kilograms of activated carbon master batches, 80 kilograms of polyester fiber-forming resins, and described special-shaped cross-section is a hollow cross-section.

[0030] 2. Preparation of bamboo charcoal moisture-conducting polyester fiber:

[0031] (1) First, the bamboo charcoal is ground into fine powder, and then the bamboo charcoal fine powder is blown with compressed air to enrich the activated carbon particles of 350nm to 500nm, and then 25~35% by weight of activated carbon with a particle size of 350~500nm and 65~ 75% polyethylene terephthalate is blended, extruded with a screw extruder, pelletized, and activated carbon masterbatches are obtained, and the blending temperature is 250~270°C, and the screw speed is 100~ 200rpm;

[0032] (2) Take 10 kilograms of activated carbon masterbatches obtained in step (1) and blend them with 80 ki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com