Rope obtained through hybrid weaving of ceramic fiber and basalt fiber

A technology of basalt fiber and ceramic fiber is applied in the field of rope nets to achieve the effects of reducing deficiencies, wide application range, good insulation and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

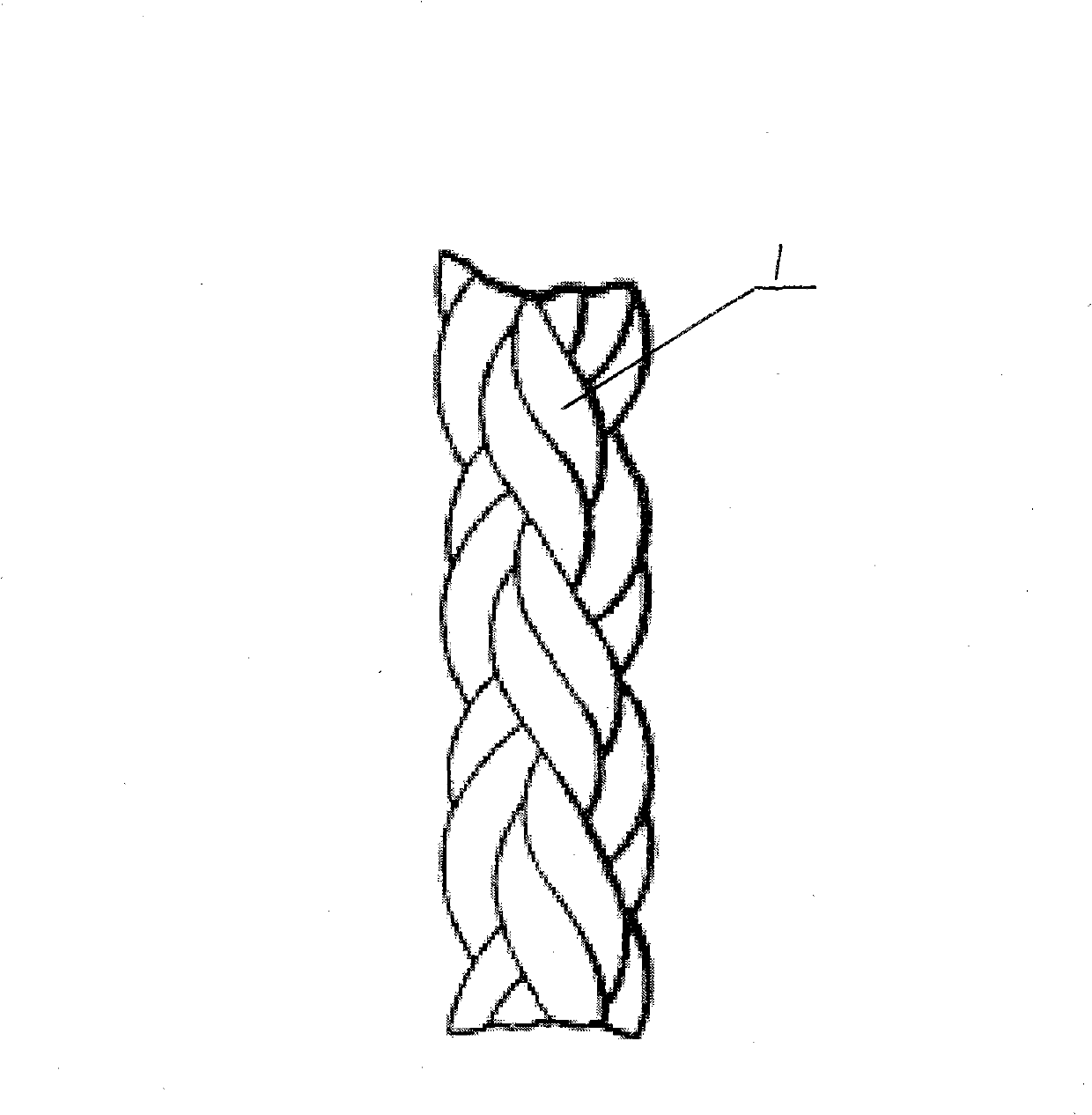

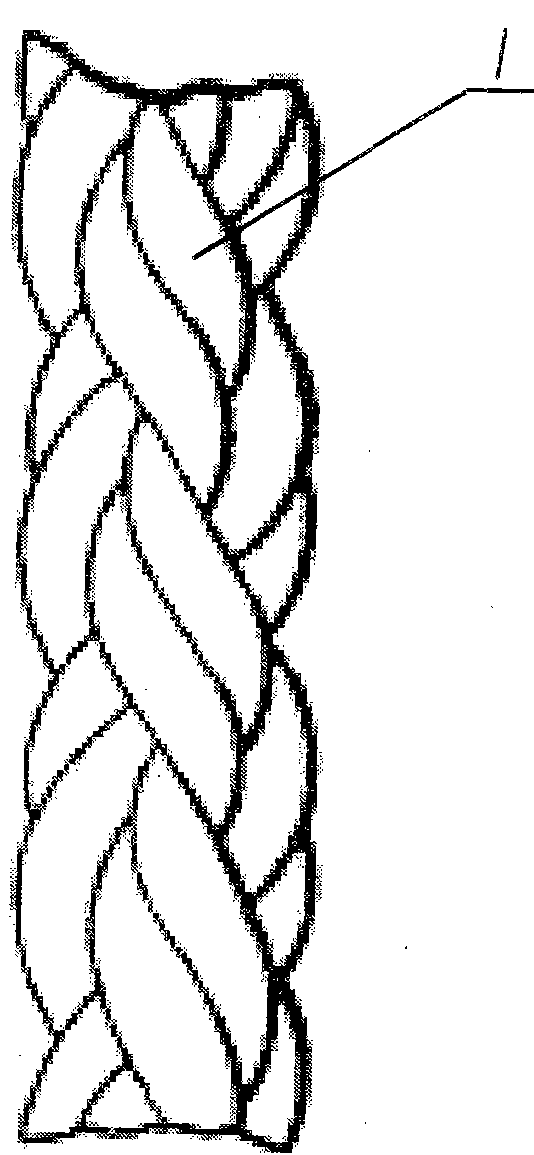

[0008] Since the ceramic fiber is relatively brittle, surface treatment can be carried out before use to increase the flexibility of the fiber. The main disadvantage of basalt fiber is that it is heavier and has poor impact resistance. Basalt fiber also needs to be surface treated before use. Ceramic fiber and basalt fiber monofilaments treated with different surface treatment agents have the advantages of softness, smoothness, hydrophobicity and low shrinkage, which make up for the shortcomings of single fibers. In the present invention, several surface-treated ceramic fiber monofilaments and basalt fiber monofilaments are twisted into rope strands 1, and several rope strands 1 are twisted into ropes according to a certain weaving method through special equipment. And the basalt fiber monofilament is 50%: 50% by mass percentage. The braiding method mentioned in the present invention can make ropes such as 6, 8, 12 or 24 strands. figure 1 It is a schematic structural diagram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com