Method for multi-dimensional sensor dynamic test device based on stable-state sine excitation force

A multi-dimensional force sensor and experimental device technology, applied in the field of multi-dimensional force sensor dynamic experimental device, can solve problems such as difficulty in ensuring synchronous loading of excitation force, large interference influence, and low test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

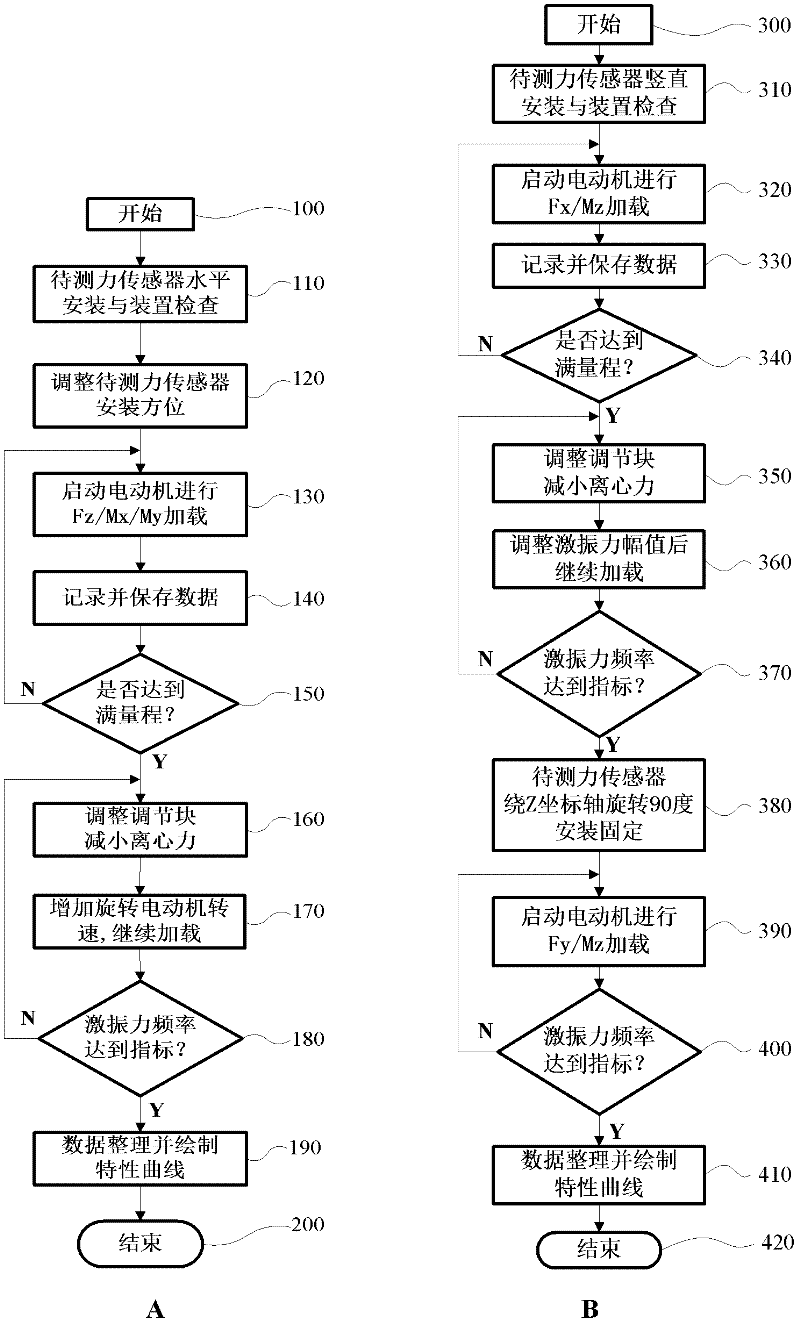

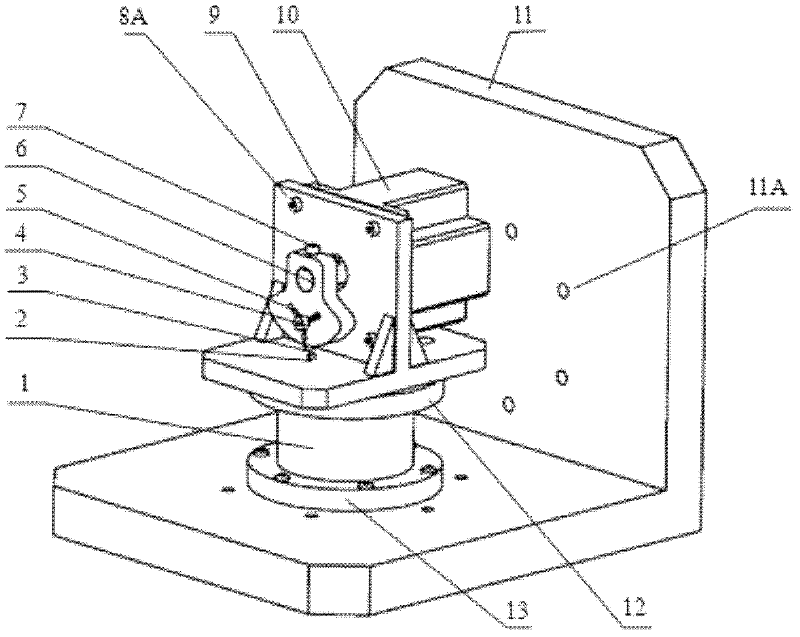

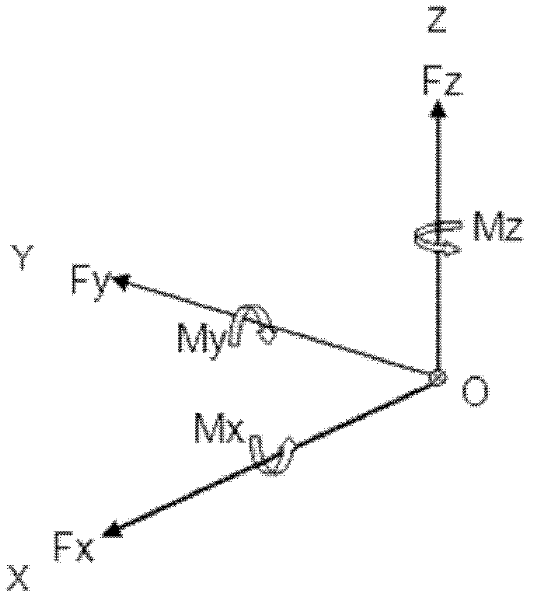

[0078] figure 1 . is a flow chart of the experimental method of the present invention. In the present invention, the centrifugal force generated by the rotation of the eccentric excitation block 5 driven by the output shaft 6 of the rotating motor is used as a dynamic excitation force and applied to the force sensor 1 to be measured to realize dynamic loading. By adjusting the rotating speed of the rotating motor 10, the weight of the eccentric excitation block 5 and the position of the center of gravity, and using the magnetic field of the permanent magnet steel block 3 to periodically excite the Hall sensor 2 to output an impulse response signal, a predictable and unaffected environment is obtained. The sinusoidal excitation force signal is used to realize the steady-state sinusoidal excitation force with stable amplitude, easy adjustment and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com