Sample preparation method and detecting method for detecting impurities in titanyl sulfate solution

A titanium oxysulfate and sample preparation technology, applied in the preparation of test samples, etc., can solve the problems of increasing the cost of analysis, the impact of strong acidic waste liquid environment, the turbidity of the detection solution, and the interference of detection and analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The sample preparation method for detecting impurities in the titanyl sulfate solution according to the present invention comprises the following steps: diluting the titanyl sulfate solution with a mixed solution of ethanol and water, thereby preparing a sample for detecting impurities in the titanyl sulfate solution.

[0018] The titanium element content of the titanyl sulfate solution may not be greater than 150g / L, for example, 50g / L˜150g / L. The pH value of the titanyl sulfate solution may be less than 1.

[0019] Titanyl sulfate solution is a titanyl sulfate solution formed after sulfuric acid reacts fully with titanium-rich materials such as titanium concentrate and acid-soluble titanium slag in the sulfuric acid method titanium dioxide production process, and most of the titanium dioxide in the titanium-rich material is decomposed. At the same time, most of the metal oxides are also decomposed into the solution in the form of sulfates such as aluminum sulfate and ...

example 1

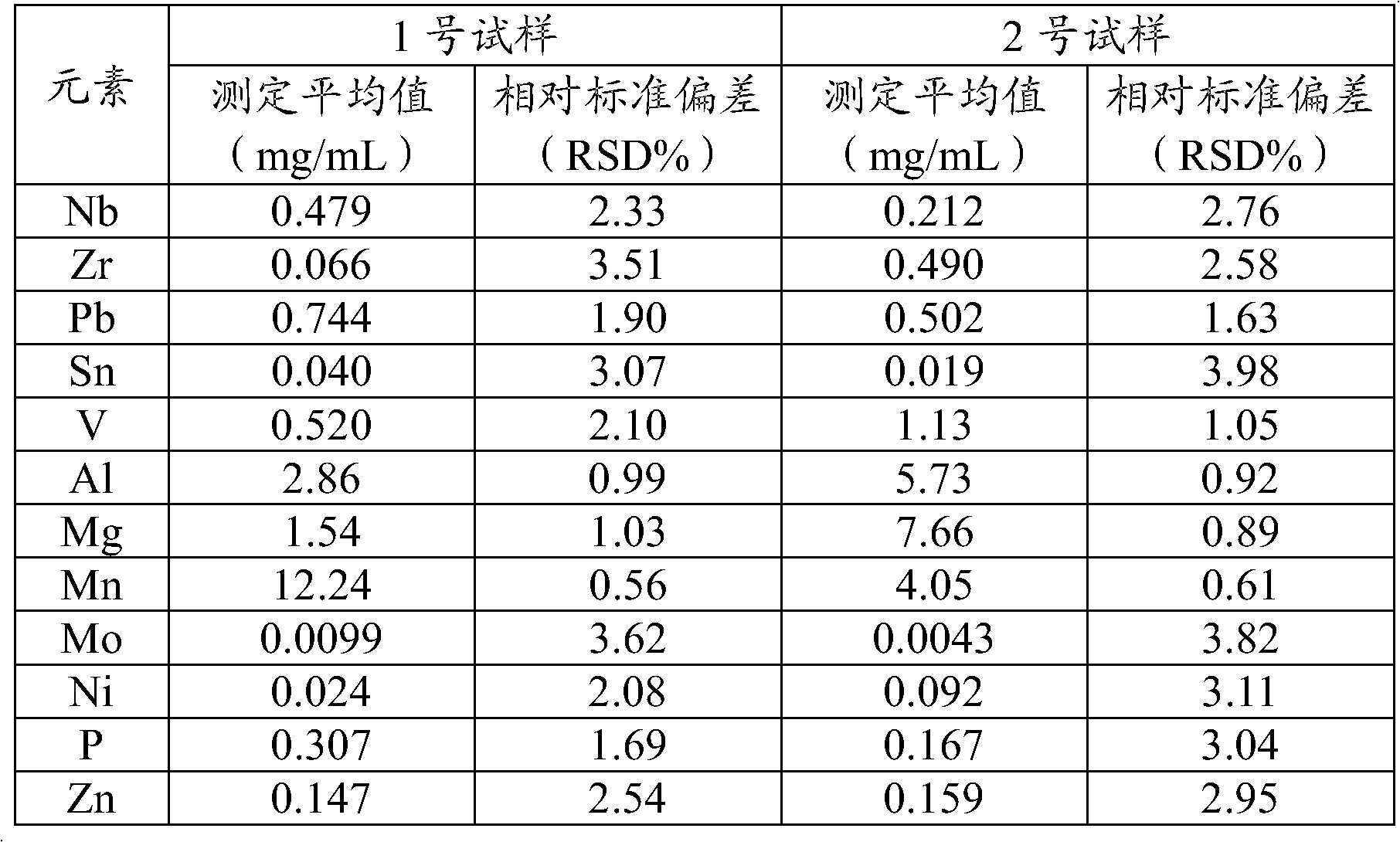

[0035] Example 1: Preparation of a sample for detection of impurities in a titanyl sulfate solution and testing the sample

[0036] In Example 1, the water used is ultra-pure grade, the ethanol is premium pure grade, and the ICP-AES is the iCAP6300 inductively coupled plasma atomic emission spectrometer from Thermo Fisher Corporation of the United States.

[0037] First, accurately extract 5.0 mL of titanyl sulfate mother liquor (titanium element content is 50 g / L, pH=0.1) with a pipette, and insert the pipette into a 100 mL volumetric flask to completely release the titanyl sulfate mother liquor in the tube; Dilute the solution composed of ethanol: water = 5:95 (volume ratio) until the volume reaches the mark, and mix evenly to prepare sample No. 1.

[0038] Then, the prepared sample solution was detected by ICP-AES, and the power of the RF generator was set to 1350W. Simultaneous analysis checks are performed directly. After each measurement of the sample solution, rinse ...

example 2

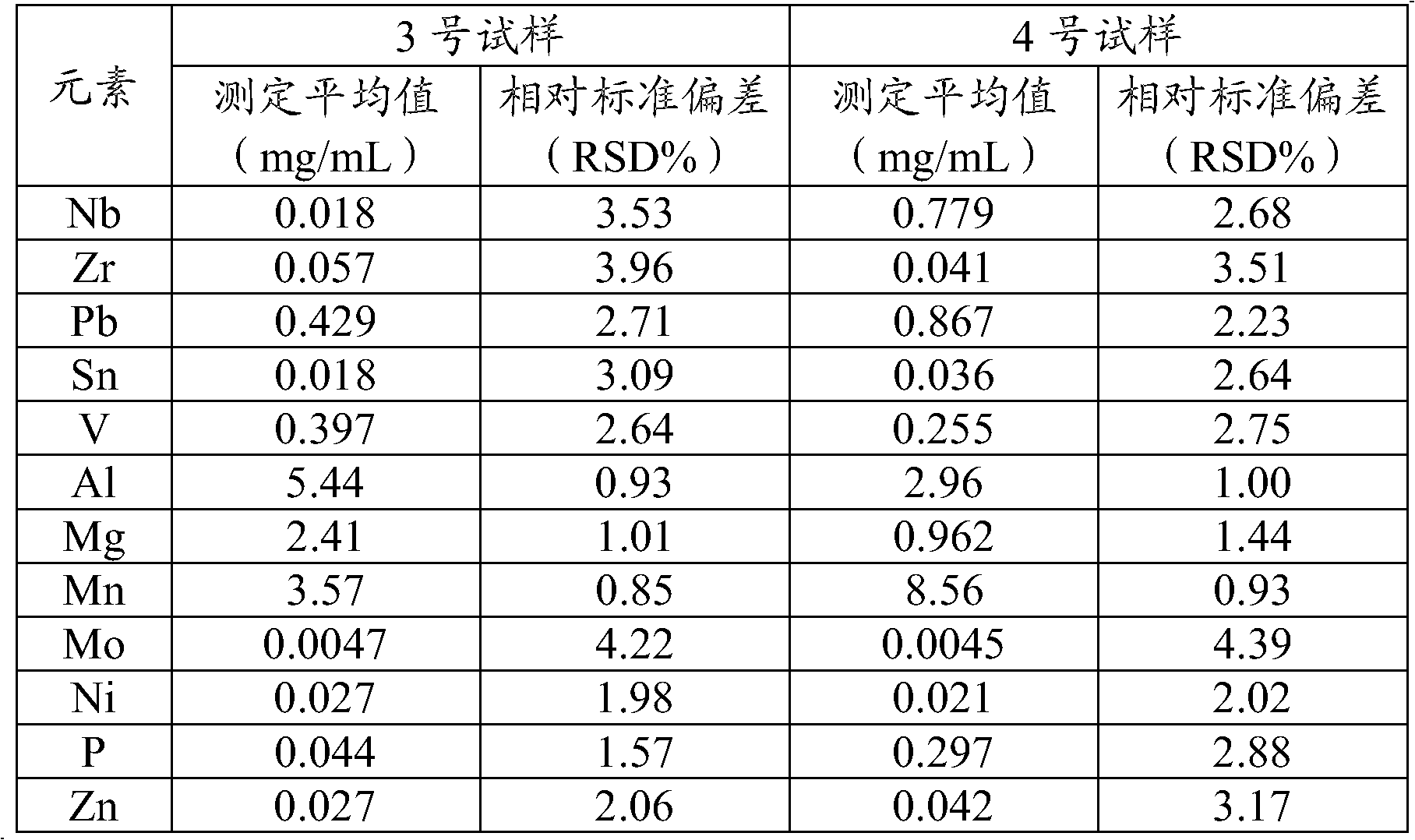

[0039] Example 2: Preparation of a sample for detection of impurities in titanyl sulfate solutions and testing of the sample

[0040] Except measuring titanyl sulfate mother liquor (titanium element content is 120g / L, pH=0.1) 10mL, diluent solution is constituted by the mixture of ethanol and water that volume ratio is 10:90, adopts the same preparation method as Example 1 to prepare Prepare sample No. 2, and test sample No. 2 with the same method as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com