Method for effectively removing tart and astringent taste of fructus phyllanthi fruit juice and application thereof

A Yunnan olive, bitter and astringent technology, applied in the field of food processing, can solve the problems of product quality decline, no successful reports, flaky crystal precipitation, etc., and achieve the effect of improving product performance, good application prospects, and moderate acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Extract the olive juice from Yunnan into a container, add glycyrrhizic acid accounting for 0.2% of the weight of the juice while stirring, and continue stirring until fully dissolved, then add calcium carbonate accounting for 0.8% of the weight of the juice, and then stir for 20 minutes; let it stand for 36 to 72 hours , extract the supernatant for later use; after filtering the precipitated layer, combine the filtrate and the supernatant, and pump to another container. Add freshly squeezed duoyi juice at a weight ratio of 5%, and inject compressed air for oxidation, ventilate for 20 to 30 minutes every 3 hours, and oxidize for 2 to 3 days; then add 100g of fresh egg white per hectoliter under stirring conditions, and then After stirring for 30 minutes, let it stand for 24 to 48 hours to complete the deacidification process, extract the supernatant to filter out the sediment, and it is the Yunnan olive juice from which the bitter and astringent taste has been removed.

...

Embodiment 2

[0029] Repeat embodiment 1, have following difference: add the glycyrrhizic acid that accounts for fruit juice weight 0.5%, add the calcium carbonate that accounts for fruit juice weight 1.5% after dissolving. Add duoyi juice in a weight ratio of 15%. Add 10g of egg white powder per hectoliter to the fruit juice after aerated oxidation.

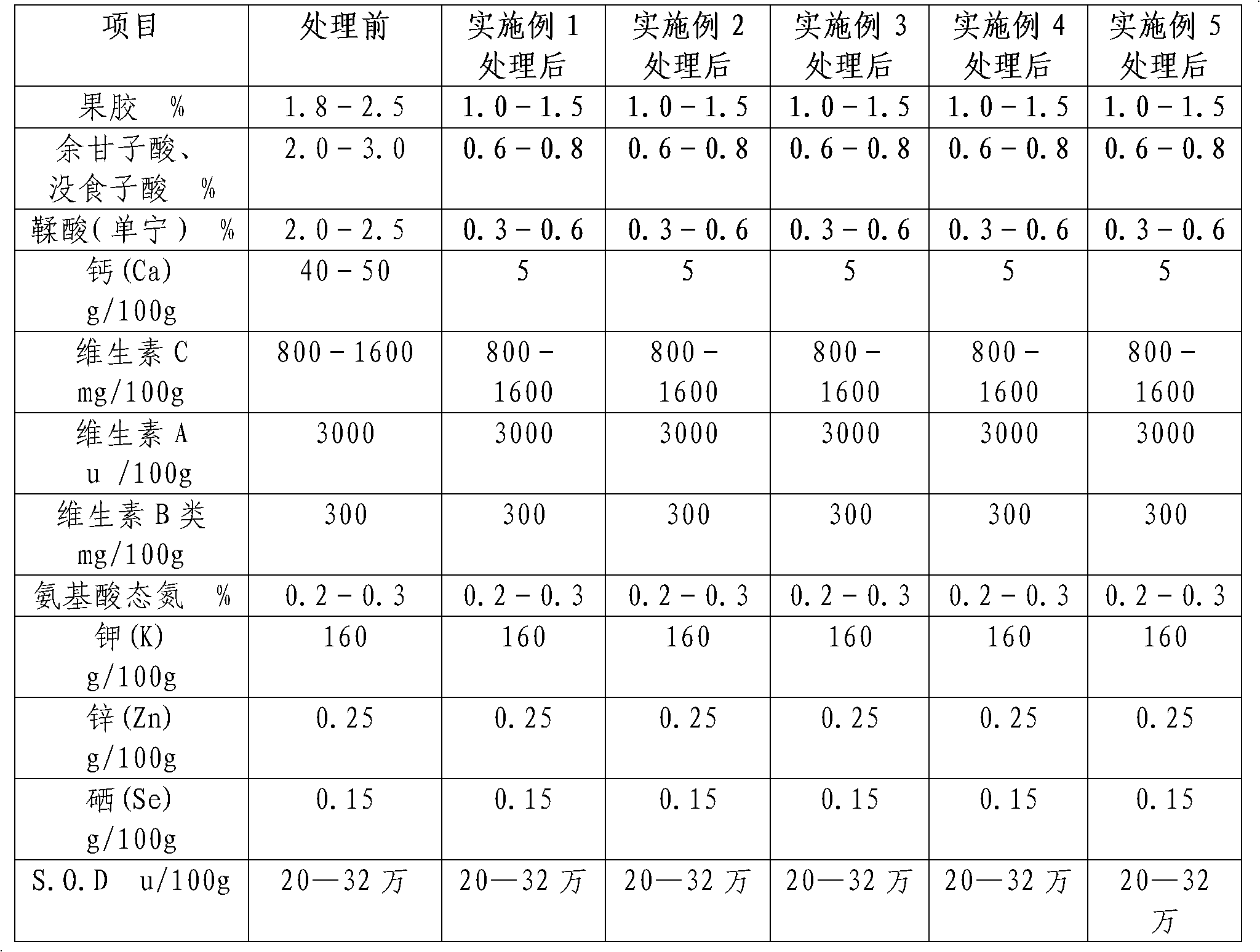

[0030] At the same time, the untreated Yunnan olive juice was used as a control to evaluate the changes in the content of active ingredients in the juice, see Table 1 for details.

Embodiment 3

[0032] Repeat embodiment 1, have following difference: add the licorice powder that accounts for fruit juice weight 5%, add after dissolving and account for fruit juice weight 0.8% calcium hydroxide. Add duoyi juice by 30% weight ratio. Add 10g of milk powder per hectoliter to the fruit juice after aerated oxidation. The licorice powder is obtained by crushing licorice through a 100-mesh sieve;

[0033] At the same time, the untreated Yunnan olive juice was used as a control to evaluate the changes in the content of active ingredients in the juice, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com