Sodium butyrate enteric sustained release preparation and preparation method thereof

A slow-release preparation, the technology of sodium butyrate, which is applied in the field of medicine, can solve the problems that the on-site operators of sodium butyrate are difficult to adapt to, the influence of the air environment is large, and the storage is inconvenient, so as to achieve improved bioavailability, good fluidity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

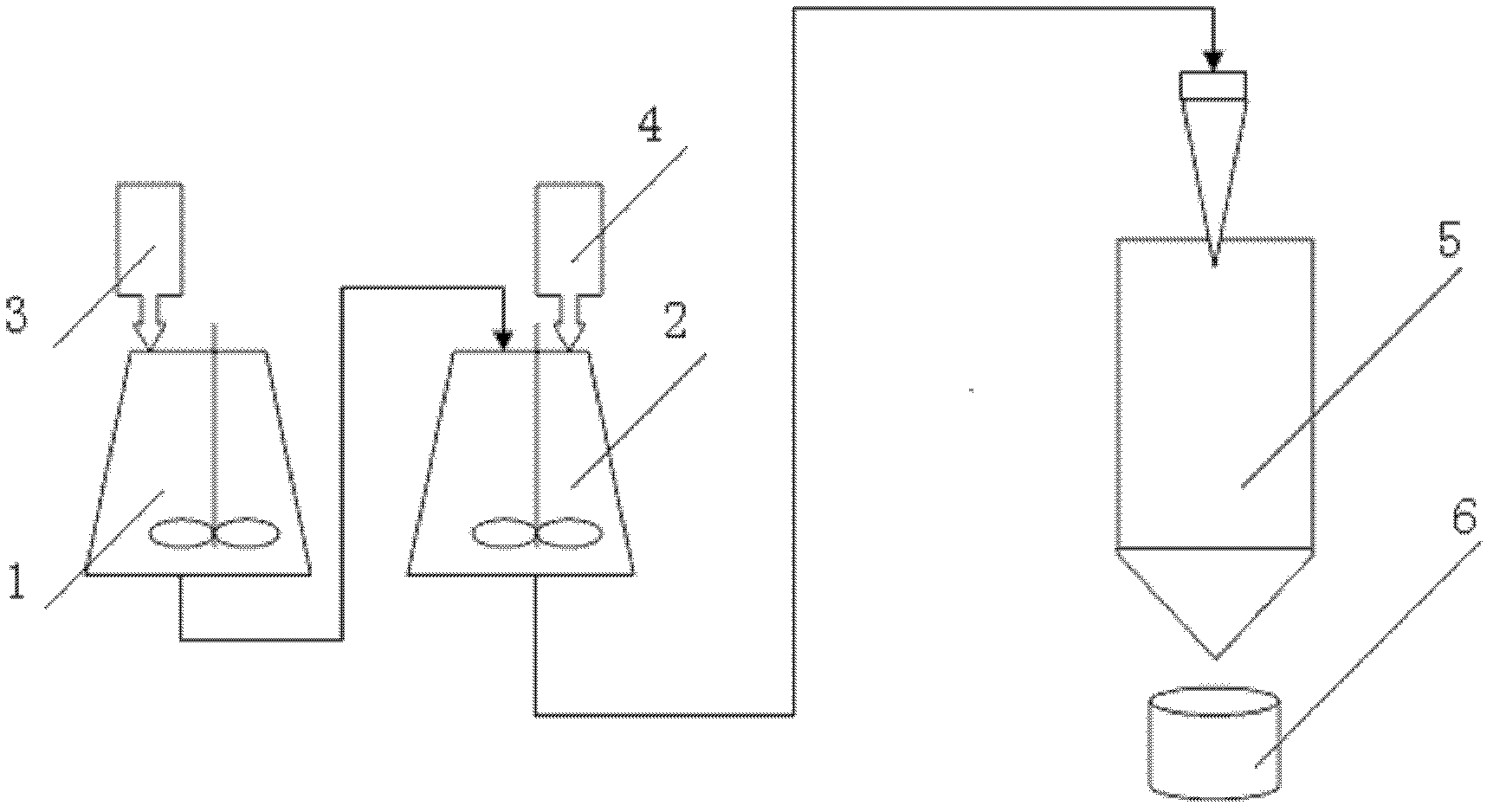

[0029] (1) see figure 1 , pump 400kg of purified water from the purified water metering tank 3 and add it to No. 1 reaction tank 1, start stirring, slowly add 175kg of sodium hydroxide, after fully dissolving, pump it into No. 2 reaction tank 2, and turn on the circulating water to control the temperature Around 50°C (48-50°C);

[0030] (2) Add 400kg of n-butyric acid to the 500L high-level metering tank 4, and then drop it into the No. 2 reaction tank 2 at a uniform speed. The temperature of the butyric acid solution is 48-50°C, and the reaction is continued for 1 hour after the dropwise addition, the reaction temperature is 50-55°C, and the pH is controlled between 7.0 and 7.5 to obtain a sodium butyrate reaction solution;

[0031] (3) Add 25 kg of ethyl cellulose, 93 kg of polyacrylic acid resin (purchased from Anhui Shanhe Pharmaceutical Excipients Co., Ltd.), 2 kg of propylene glycol, and glycerin monostearate to the above-mentioned sodium butyrate reaction solution (con...

Embodiment 2

[0035] (1) Pump 400kg of purified water from the purified water metering tank 3 and add it to No. 1 reaction tank 1, start stirring, slowly add 175kg of sodium hydroxide, after fully dissolving, pump it into No. 2 reaction tank 2, and turn on the circulating water Control the temperature at around 50°C;

[0036] (2) Add 400kg of n-butyric acid to the 500L high-level metering tank 4, and drop it into the No. 2 reaction tank 2 at a uniform speed. The temperature of the solution during the acid is controlled at 50-55°C; the dropwise addition is completed and the reaction is continued for 1 hour, the pH is controlled between 7.0 and 7.5, and the reaction temperature is 65-70°C to obtain a sodium butyrate reaction solution;

[0037] (3) Add 5kg of ethyl cellulose, 50kg of polyacrylic resin, 3kg of polypropylene glycol, 10kg of glyceryl monostearate, 432kg of beta cyclodextrin to the above reaction solution (containing about 500kg of sodium butyrate), and shear emulsify 10- 20 minu...

Embodiment 3

[0041] (1) Pump 400kg of purified water from the purified water metering tank 3 and add it to No. 1 reaction tank 1, start stirring, slowly add 175kg of sodium hydroxide, after fully dissolving, pump it into No. 2 reaction tank, and turn on the circulating water control The temperature is around 50°C;

[0042] (2) Add 400kg of n-butyric acid to the 500L high-level metering tank, drop it into the reaction tank at a constant speed, use circulating water to cool down and control the temperature at a maximum of 85°C, and finish the dropwise addition in 2 hours. The solution when adding n-butyric acid dropwise The temperature is 48-55°C; after the dropwise addition, the reaction is continued for 1.2 hours, the reaction temperature is 50-55°C, and the pH is controlled between 7.0 and 7.5 to obtain a sodium butyrate reaction solution;

[0043] (3) Add 5kg of ethyl cellulose, 50kg of polyacrylic resin, 5kg of propylene glycol, 20kg of glyceryl monostearate, 253kg of β-cyclodextrin to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com