Process method for regenerating ionic liquid and separating and recovering absorbents

A technology of ionic liquids and process methods, which is applied in the fields of ionic liquid regeneration and absorbent separation and recovery, can solve the problems of inability to obtain high-purity ionic liquids, the regeneration process takes a long time, and the slow diffusion process of absorbents, etc., to achieve resource recovery. , improve regeneration efficiency, and solve the effect of difficult regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

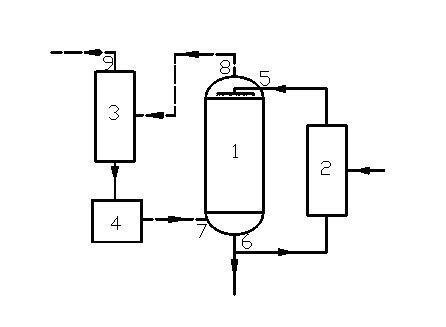

Image

Examples

Embodiment 1

[0033] This example illustrates the use of water vapor for 2 1-butyl-3-methylimidazolium tetrafluoroborate for regeneration and SO 2 For separation and recovery, a packed tower is used as the regeneration tower, and the purging conditions are 110°C and 0.10 MPa.

[0034] Will SO 2 Add 1-butyl-3-methylimidazolium tetrafluoroborate with a content of 12.0% into the ionic liquid storage tank, heat the storage tank to 110°C, and transport the ionic liquid to the regeneration tower through a pump, and the regeneration tower is used as filler The tower is equipped with Raschig rings as packing. The upper part of the regeneration tower is equipped with a liquid distribution device, and the lower part is equipped with a gas distribution device. Control the temperature in the tower to 110°C, adjust the gas flow rate so that the volume ratio of the ionic liquid to the water vapor is 1:2000, and the pressure is 0.10 MPa. The ionic liquid is sprayed from the top of the tower through the...

Embodiment 2

[0037] This example illustrates the use of ethanol vapor for 2 1-butyl-3-methylimidazolium bromide for regeneration and SO 2 For separation and recovery, a plate tower is used as the regeneration tower, and the purging conditions are a temperature of 90°C and a pressure of 0.10 MPa.

[0038] Will SO 2 Add 1-butyl-3-methylimidazolium bromide with a content of 10% into the ionic liquid storage tank, heat the storage tank to 90°C, and transport the ionic liquid to the regeneration tower through a pump, and the regeneration tower is a plate tower. Control the temperature in the tower to 90°C, adjust the gas flow so that the volume ratio of ionic liquid to ethanol vapor is 1:2500, and the pressure is 0.10 MPa. The ionic liquid is sprayed from the top of the tower through the circulation pump, and the gas enters from the bottom of the tower , discharged from the top of the tower, the steam is contacted with the ionic liquid for mass transfer, and after 1 hour of countercurrent con...

Embodiment 3

[0041] This example illustrates the use of water vapor for 2 Tetramethylguanidine lactate for regeneration and SO 2 For separation and recovery, a bubble column is used as the regeneration column, and the purging conditions are temperature 120°C and pressure 0.10 MPa. And compared with the traditional method, it shows the advantages of this method.

[0042] Will SO 2 Tetramethylguanidine lactate with a content of 15.0% is added to the ionic liquid storage tank, the storage tank is heated to 120°C, and the ionic liquid is transported to the regeneration tower through a pump, and the regeneration tower is a bubble tower. Control the temperature in the tower to 120°C, adjust the gas flow so that the volume ratio of ionic liquid to water vapor is 1:5000, and the pressure is 0.10 MPa. Exhausted from the top, the sweeping gas is in contact with the ionic liquid for mass transfer, and after purging for 1 hour by the bubbling method, the SO in the ionic liquid 2 The content can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com