Preparation method of superhydrophilic polydimethylsiloxane film on basis of nano forest template

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of superhydrophilic polydimethylsiloxane film preparation, can solve the problem of difficult to achieve superhydrophilic PDMS film with extremely small contact angle , The super-hydrophilic properties of PDMS films are difficult to maintain for a long time, and the uniformity of super-hydrophilicity is difficult to guarantee, so as to achieve the effects of stable super-hydrophilic properties, low cost and small contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

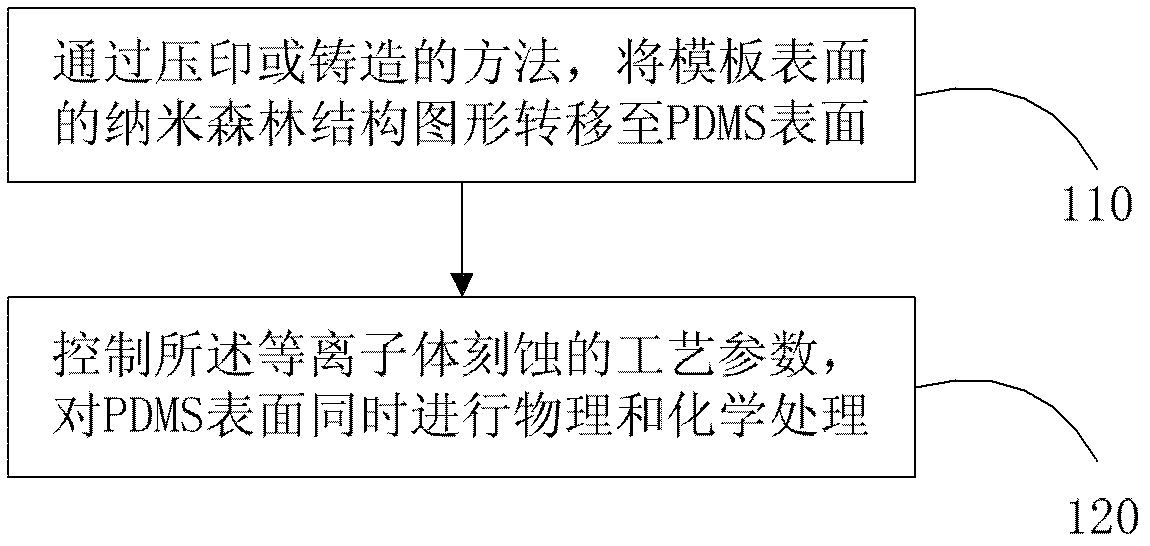

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Mix the PDMS polymer body and the polymer initiator according to the mass ratio of 5:1 to 20:1 to form a PDMS prepolymer, then place it in a sealed cavity, and use a vacuum pump to pump the gas for 10 to 45 minutes. Until no air bubbles remain in the PDMS prepolymer;

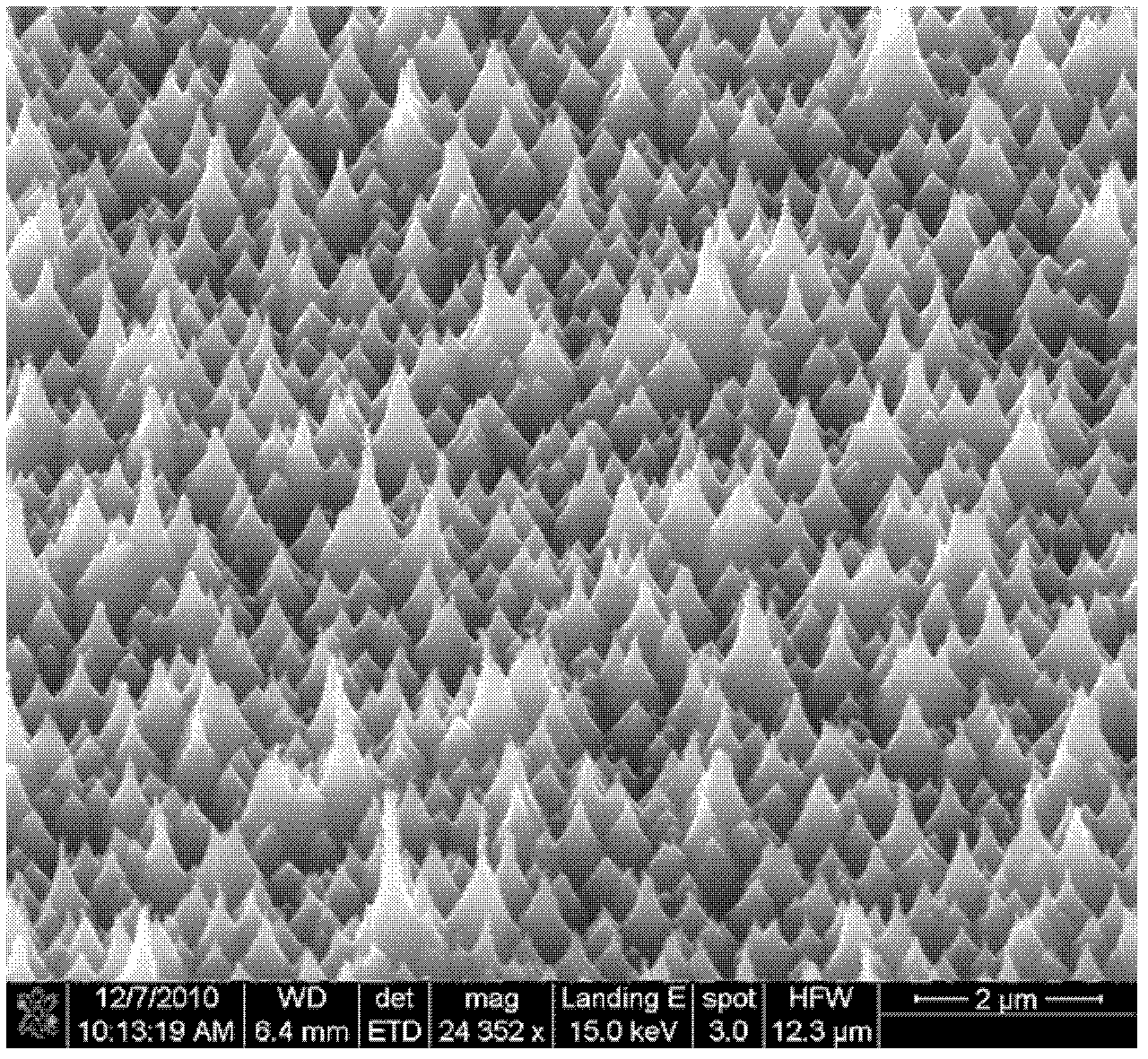

[0033] Step 2: Place the template with a dense nano-forest structure surface on the bottom of the PDMS prepolymer, then place it in a sealed cavity, and use a vacuum pump to pump the gas for 10 to 45 minutes until no bubbles remain in the PDMS prepolymer;

[0034] Step 3: Place the PDMS prepolymer in step 2 in an oven for heating and curing at a temperature of 70-100°C for 1-2 hours;

[0035] Step 4: peel off the PDMS film from the surface of the template with a dense nano-forest structure to obtain a PDMS film with a dense nano-array structure surface;

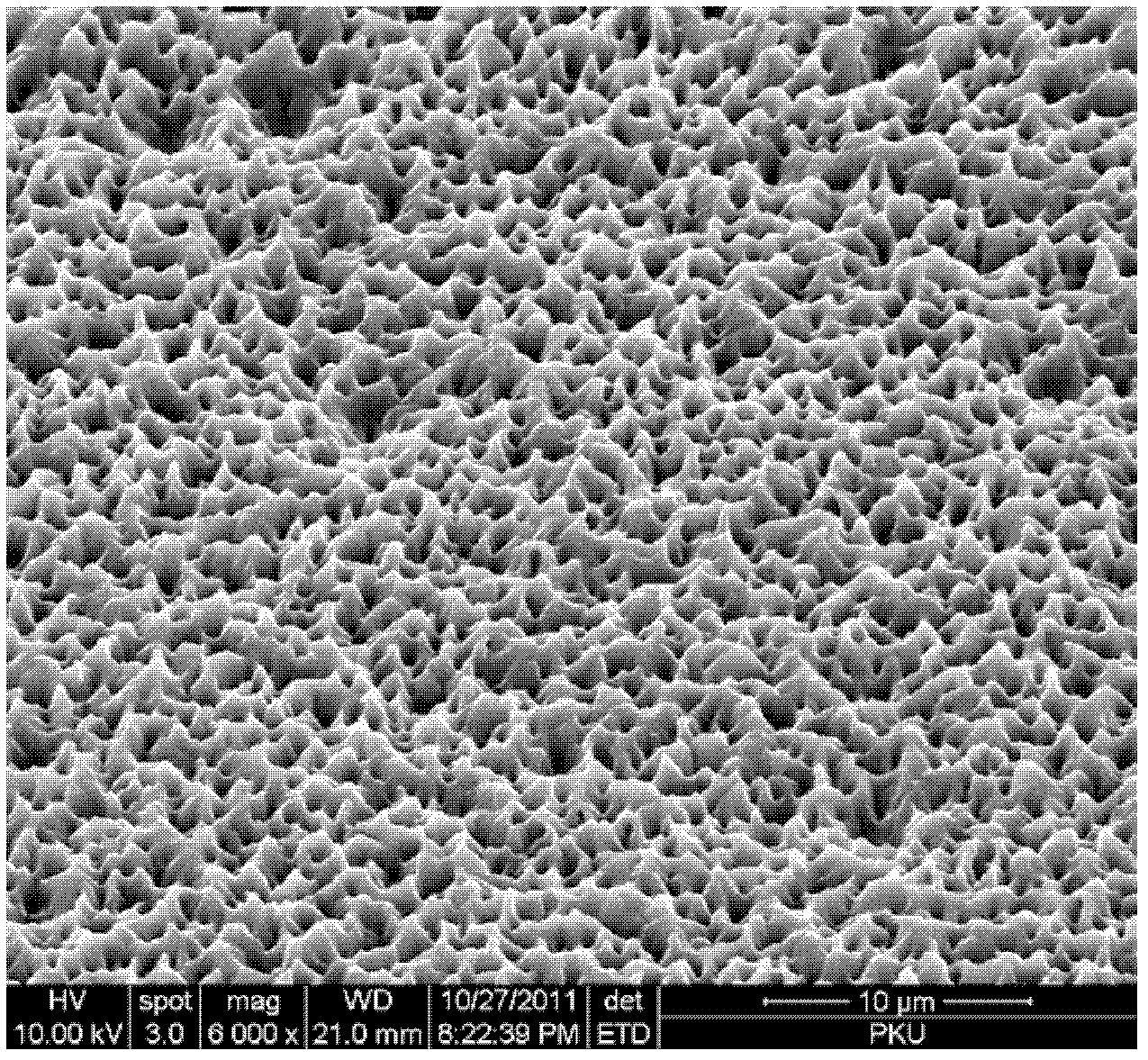

[0036] Step 5: Control the process parameters of deep reactive ion etching equipment, and sequentially feed SF 6 , O 2 and CHF 3 Gas surface...

Embodiment 2

[0043] Step 1: Mix the PDMS polymer body and the polymer initiator according to the mass ratio of 5:1 to 20:1 to form a PDMS prepolymer, then place it in a sealed cavity, and use a vacuum pump to pump the gas for 10 to 45 minutes. Until no air bubbles remain in the PDMS prepolymer;

[0044] Step 2: heat the PDMS prepolymer in an oven to form a soft PDMS semi-solid at a temperature of 50-70°C for 15-30 minutes;

[0045] Step 3: Place the template with a dense nano-forest structure surface on top of the PDMS semi-solid, and then press the template evenly to make the template and the PDMS semi-solid tightly combined;

[0046] Step 4: Place the PDMS semi-solid in step 3 in an oven for heating and curing at a temperature of 70-100°C for 1-2 hours;

[0047] Step 5: peeling off the PDMS film from the surface of the template with a dense nano-forest structure to obtain a PDMS film with a dense nano-array structure surface;

[0048] Step 6: Control the process parameters of deep reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com