Method for preparing oil soluble semiconductor nanocrystalline without phosphine

An oil-soluble, semiconductor technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult control of selenium reactivity, unsuitable for industrial production of nanocrystals, high reaction temperature, and achieve good experimental repeatability, The effect of reducing the preparation cost and easy experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.08g of Se powder into the mixed solution of 0.5ml of oleylamine and 0.5ml of dodecyl mercaptan, stir in the air, and wait until the Se powder is completely dissolved to obtain a wine red solution. This solution was used as a Se precursor for the synthesis of semiconductor nanocrystals.

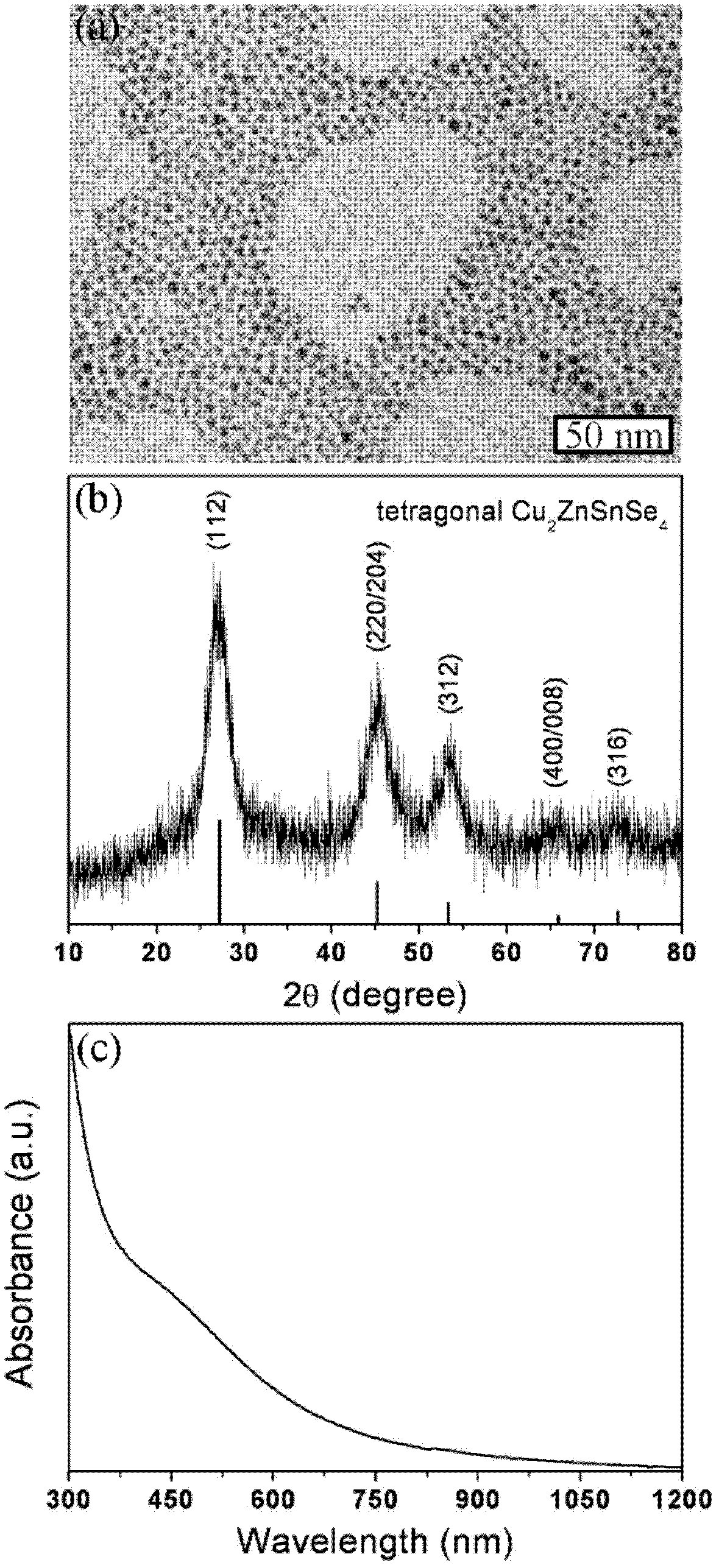

[0024] 0.085g CuCl 2 2H 2 O, 0.056g SnCl 2 2H 2 O, 0.034g ZnCl 2 1. Add 1ml of dodecyl mercaptan to 10ml of oleylamine. The reaction system was evacuated and nitrogen was blown 3 times, 10 minutes each time. Then heated to 60 ° C under vacuum conditions for 0.5 hours, the CuCl 2 2H 2 O, SnCl 2 2H 2 O and ZnCl 2 Dissolved to obtain a milky white solution. then in N 2 The temperature of the solution was raised to 180°C under gas protection, and the previously prepared Se precursor was injected, and the reaction was continued at 180°C for 30 minutes, as shown in figure 1 As shown, get Cu 2 ZnSnSe 4 semiconductor nanocrystals.

Embodiment 2

[0026] Add 0.08g of Se powder into the mixed solution of 0.5ml of oleylamine and 0.5ml of dodecyl mercaptan, stir in the air, and wait until the Se powder is completely dissolved to obtain a wine red solution. This solution was used as a Se precursor for the synthesis of semiconductor nanocrystals.

[0027] 0.085g CuCl 2 2H 2 0.0.056g SnCl 2 2H 2 O, 0.068g ZnCl 2 1. Add 1ml of dodecyl mercaptan to 10ml of oleylamine. The reaction system was evacuated and nitrogen was blown 3 times, 10 minutes each time. Then heated to 60°C under vacuum for 0.5 hours to react the CuCl 2 2H 2 O, SnCl 2 2H 2 O and ZnCl 2 Dissolved to obtain a milky white solution. then in N 2Under the protection of gas, the solution was heated to 180°C, the Se precursor was injected, and the reaction was carried out for 30 minutes to obtain Cu 2 ZnSnSe 4 semiconductor nanocrystals.

Embodiment 3

[0029] Add 0.08g of Se powder into the mixed solution of 0.5ml of oleylamine and 0.5ml of dodecyl mercaptan, stir in the air, and wait until the Se powder is completely dissolved to obtain a wine red solution. This solution was used as a Se precursor for the synthesis of semiconductor nanocrystals.

[0030] 0.085g CuCl 2 2H 2 O, 0.056g SnCl 2 2H 2 O, 0.136g ZnCl 2 1. Add 1ml of dodecyl mercaptan to 10ml of oleylamine. The reaction system was evacuated and nitrogen was blown 3 times, 10 minutes each time. Then heated to 60°C under vacuum for 0.5 hours to react the CuCl 2 2H 2 O, SnCl 2 2H 2 O and ZnCl 2 Dissolved to obtain a milky white solution. then in N 2 Under the protection of gas, the solution was heated to 180°C, the Se precursor was injected, and the reaction was carried out for 30 minutes to obtain Cu 2 ZnSnSe 4 semiconductor nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com