Method for preparing organic montmorillonite by modifying with fatty amine solution process

A technology of organic montmorillonite and aliphatic amines, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as retention, limitation of montmorillonite application, high production cost of organic montmorillonite, and achieve low price , Remarkable modification effect, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

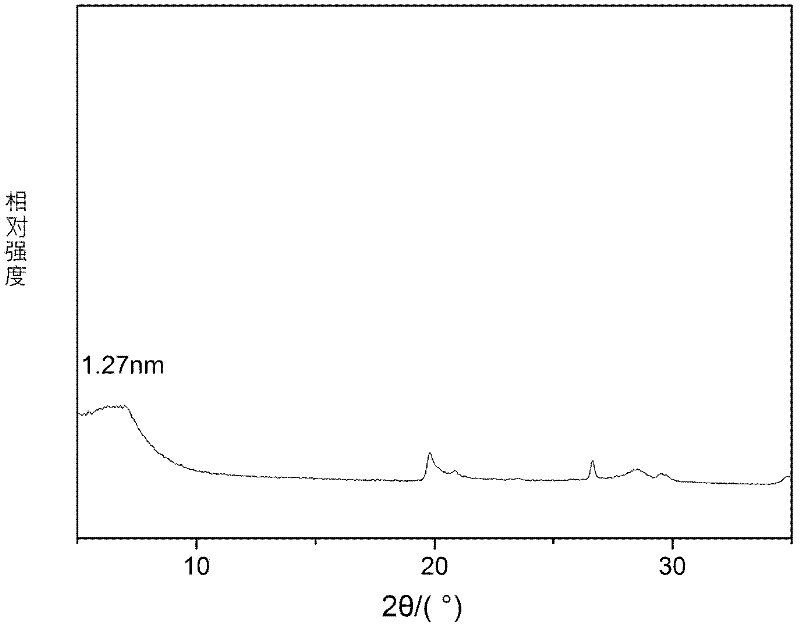

[0029] Take 10g of Na-based montmorillonite (provided by Zhejiang Sanding Technology Co., Ltd.) into a 500ml three-necked flask, add 200ml of distilled water, stir and heat to 80°C to prepare a montmorillonite suspension;

[0030] Add another 5g of dodecyl primary amine (fatty amine) into a beaker filled with 100ml of distilled water, heat to 80°C, wait until the fatty amine floating on the water surface melts, add concentrated hydrochloric acid (molar concentration: 11.9mol / L) dropwise 3.45ml and stirring, during this process, a white emulsion with bubbles is continuously formed, until the fatty amine is completely dissolved in water, and a white emulsion is completely formed, and the amine salt solution after acidification of the fatty amine is prepared;

[0031] Add the fatty amine acidified amine salt solution (milky white amine salt solution) gradually into the montmorillonite suspension, the reaction temperature is 80°C, and the stirring reaction time is 3 hours, so that ...

Embodiment 2

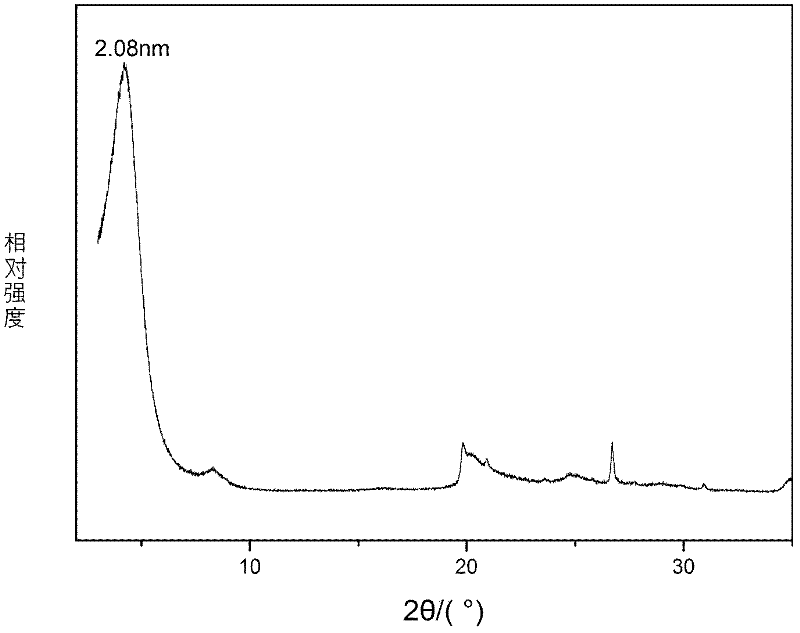

[0034] Take 37.5g of sodium-based montmorillonite (provided by Zhejiang Sanding Technology Co., Ltd.) into a 1000ml three-necked flask, add 400ml of distilled water, stir and heat to 90°C to prepare a montmorillonite suspension;

[0035] Another 15g of hexadecyl primary amine (fatty amine) was added to a beaker filled with 250ml of distilled water, heated to 90°C, and until the fatty amine was completely melted, 6ml of glacial acetic acid (density 1.049g / ml) was slowly added dropwise and stirred. During this process, a white emulsion with bubbles is continuously generated until the fatty amine is completely dissolved in water to form a white emulsion, and an amine salt solution after acidification of the fatty amine is prepared;

[0036] Add the fatty amine acidified amine salt solution (milky white amine salt solution) gradually into the montmorillonite suspension, the reaction temperature is 90°C, and the stirring reaction time is 6 hours, so that the amine salt formed after ...

Embodiment 3

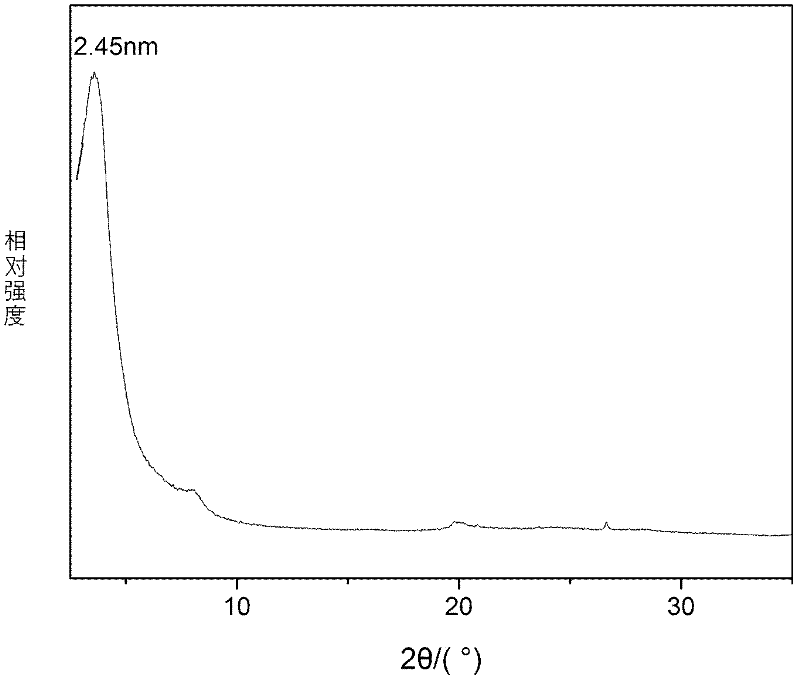

[0039] Take 26.6g of sodium-based montmorillonite (provided by Zhejiang Sanding Technology Co., Ltd.) into a 1000ml three-necked flask, add 400ml of distilled water, stir and heat to 100°C to prepare a montmorillonite suspension;

[0040]Add another 8g of octadecyl primary amine (fatty amine) into a beaker filled with 150ml of distilled water, heat to 90°C, wait until the fatty amine is completely melted, slowly add 3.78ml of concentrated hydrochloric acid (molar concentration: 11.9mol / L) dropwise and stirring, during this process, a white emulsion with bubbles is continuously formed until the fatty amine is completely dissolved in water to form a white emulsion, and the acidified amine salt solution of the fatty amine is prepared;

[0041] Add the fatty amine acidified amine salt solution (milky white amine salt solution) gradually into the montmorillonite suspension, the reaction temperature is 100°C, and the stirring reaction time is 9 hours, so that the amine salt formed af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com