Quick synthesis method of heteroatomic aluminophosphate molecular sieve SAPO-5 in eutectic body

A technology of SAPO-5 and aluminum phosphorus molecular sieve, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of long crystallization time, environmental pollution, hidden safety hazards, etc., and achieve a safe environment, molecular sieve The effect of fast crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

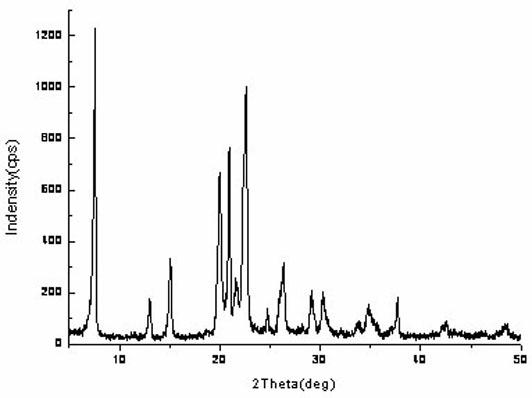

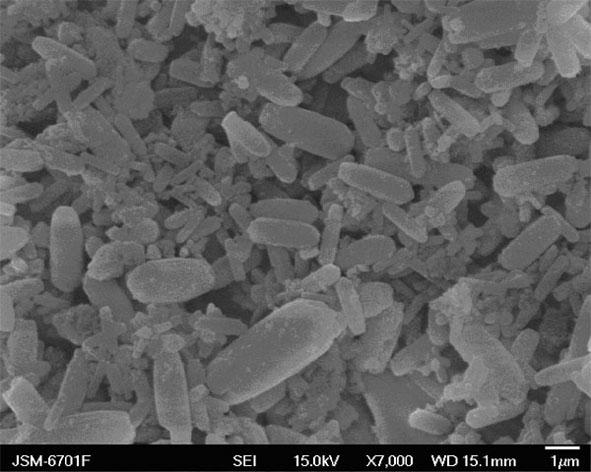

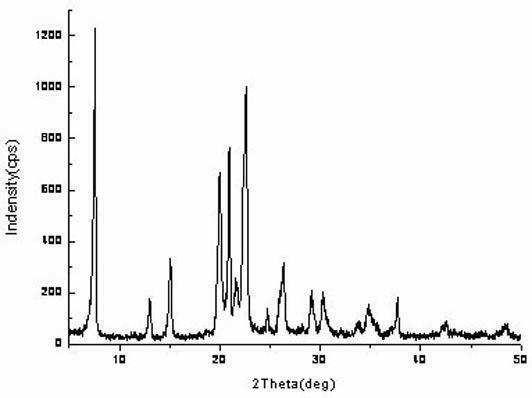

[0015] After 2.8g of pentaerythritol, 8.4g of choline chloride, 0.222g of pseudoboehmite and 0.036g of white carbon black were mixed uniformly, they were transferred to a three-necked flask, and then 0.21ml of phosphoric acid and 0.034g of hydrofluoric acid were added to form a mixture ( Mole ratio) is: 54DES:1.0P 2 o 5 :Al 2 o 3 :0.45HF:0.4SiO 2 ; Heat the mixture to 120-125°C and mix well; the above mixture is heated to 180°C under microwave radiation, and crystallized under normal pressure for 60 minutes; the above reaction mixture is cooled to room temperature, vacuum filtered, and the product is washed repeatedly with water and acetone , and dried at 80° C. for 3 hours to obtain a powder product. Such as figure 1 , figure 2 Shown, through XRD detection, this powder product is SAPO-5 molecular sieve.

Embodiment 2

[0017] After 2.8g of pentaerythritol, 8.4g of choline chloride, 0.222g of pseudoboehmite and 0.036g of white carbon black were mixed uniformly, they were transferred to a three-necked flask, and then 0.42ml of phosphoric acid and 0.038g of hydrofluoric acid were added to form a mixture ( Mole ratio) is: 54DES:2.0P 2 o 5 :Al 2 o 3 :0.5HF:0.4SiO 2 ; Heat the mixture to 120-125°C and mix well; the above mixture is heated to 180°C under microwave radiation, and crystallized under normal pressure for 60 minutes; the above reaction mixture is cooled to room temperature, vacuum filtered, and the product is washed repeatedly with water and acetone , and dried at 80° C. for 3 hours to obtain a powder product. Such as figure 1 , figure 2 Shown, through XRD detection, this powder product is SAPO-5 molecular sieve.

Embodiment 3

[0019] After 2.8g of pentaerythritol, 8.4g of choline chloride, 0.222g of pseudoboehmite and 0.036g of white carbon black were mixed uniformly, they were transferred to a three-necked flask, and then 0.42ml of phosphoric acid and 0.070g of hydrofluoric acid were added to form a mixture ( Mole ratio) is: 54DES:2.0P 2 o 5 :Al 2 o 3 :0.93HF:0.4SiO 2 ; Heat the mixture to 120-125°C and mix well; the above mixture is heated to 180°C under microwave radiation, and crystallized under normal pressure for 60 minutes; the above reaction mixture is cooled to room temperature, vacuum filtered, and the product is washed repeatedly with water and acetone , and dried at 80° C. for 3 hours to obtain a powder product. Such as figure 1 , figure 2 Shown, through XRD detection, this powder product is SAPO-5 molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com