Preparation method of monolayer MoS2 nano-sheet solution

A nanosheet and solution technology, applied in the field of nanomaterials, can solve the problems of no clear report on the stability of single-layer MoS2 solution, harsh reaction conditions, and difficult industrialization, etc., to achieve short preparation cycle, improved solubility and dispersion, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

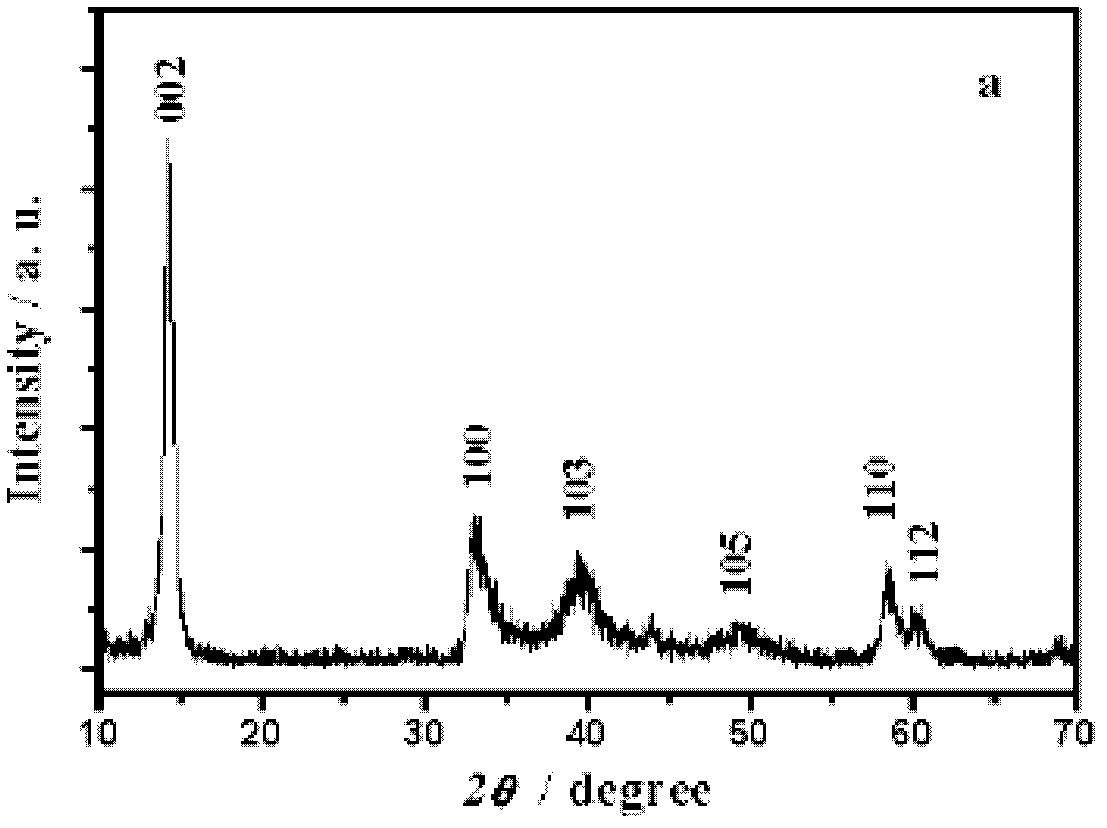

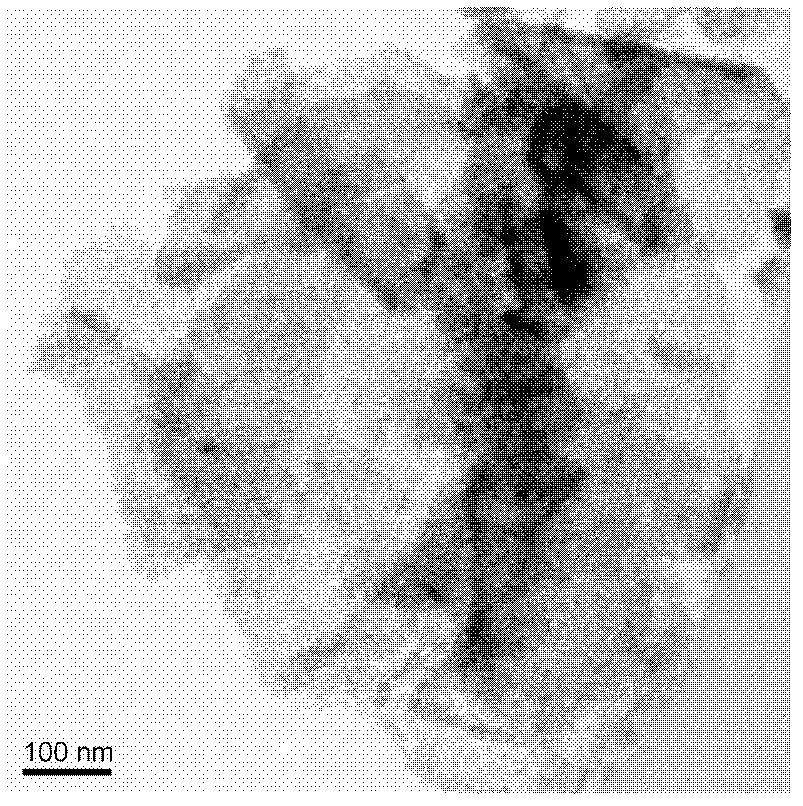

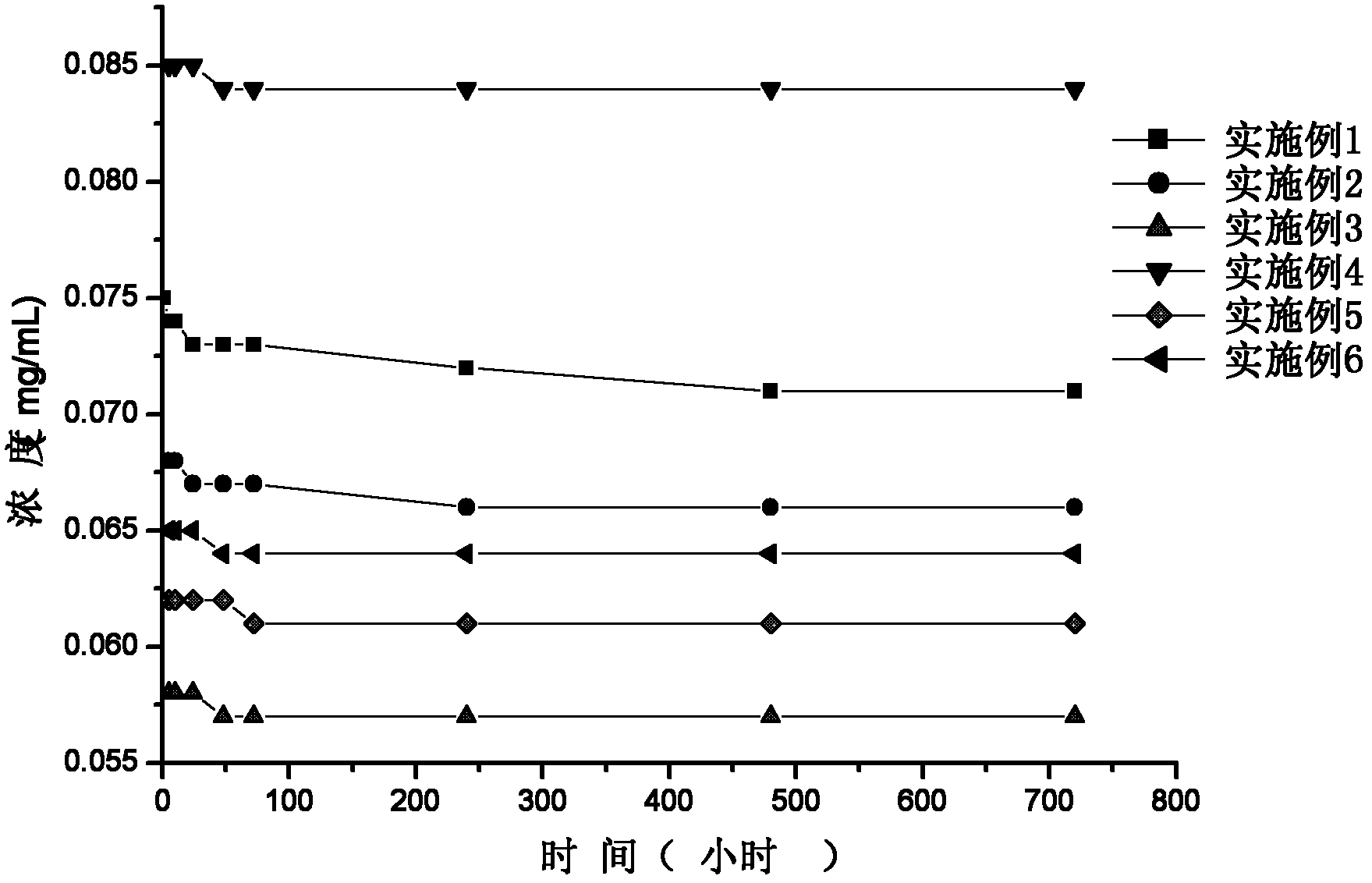

[0019] Take 100ml of N-methylpyrrolidone solvent, add 50mg of MoS to it 2 Put the powder on a magnetic stirrer and stir for 30 minutes, transfer the solution into a 150ml hydrothermal reaction kettle, place it in an oven, set the reaction temperature to 120°C, and the reaction time to 6h. After the reaction, the solution was taken out and placed in a beaker, and 0.5 g of cetyltrimethylammonium bromide was added to the solution, and stirred on a magnetic stirrer for 30 minutes. Then place the beaker in an ultrasonic pulverizer for ultrasonic exfoliation, set the power of the ultrasonic pulverizer to 180w, and the ultrasonic time to 2h. The solution treated by the ultrasonic pulverizer was centrifuged for 2 hours, and the speed of the centrifuge was 800 rpm / h. Take the supernatant to get monolayer MoS 2 nanosheet solution.

Embodiment 2

[0021] Take 100ml N-vinylpyrrolidone, add 100mg MoS to it 2 Put the powder on a magnetic stirrer and stir for 30 minutes, transfer the solution into a 150ml hydrothermal reaction kettle, place it in an oven, set the reaction temperature to 100°C, and the reaction time to 7h. After the reaction, the solution was taken out and placed in a beaker, and 1.0 g of cetyltrimethylammonium chloride was added to the solution, and stirred on a magnetic stirrer for 30 minutes. Then place the beaker in an ultrasonic pulverizer for ultrasonic exfoliation, set the power of the ultrasonic pulverizer to 200w, and the ultrasonic time to 1h. The solution treated by the ultrasonic pulverizer was centrifuged for 1 h, and the speed of the centrifuge was 1400 rpm / h. Take the supernatant to get monolayer MoS 2 nanosheet solution.

Embodiment 3

[0023] Take 50ml of N-dodecylpyrrolidone and add 60mg of MoS to it 2 Put the powder on a magnetic stirrer and stir for 30 minutes, transfer the solution into a 150ml hydrothermal reaction kettle, place it in an oven, set the reaction temperature to 80°C, and the reaction time to 8h. After the reaction, the solution was taken out and placed in a beaker, and 1.0 g of cetyltrimethylammonium bromide was added to the solution, and stirred on a magnetic stirrer for 30 minutes. Then place the beaker in an ultrasonic pulverizer for ultrasonic exfoliation, set the power of the ultrasonic pulverizer to 200w, and the ultrasonic time to 1h. The solution treated by the ultrasonic pulverizer was centrifuged for 2 h, and the speed of the centrifuge was 1000 rpm / h. Take the supernatant to get monolayer MoS 2 nanosheet solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com