Preparation method for bismuth ferrate nano fibers

A technology of nanofibers and bismuth ferrite, applied in nanotechnology, chemical instruments and methods, iron compounds, etc., can solve the problems that visible light cannot be absorbed well, and cannot meet the high-efficiency absorption of sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

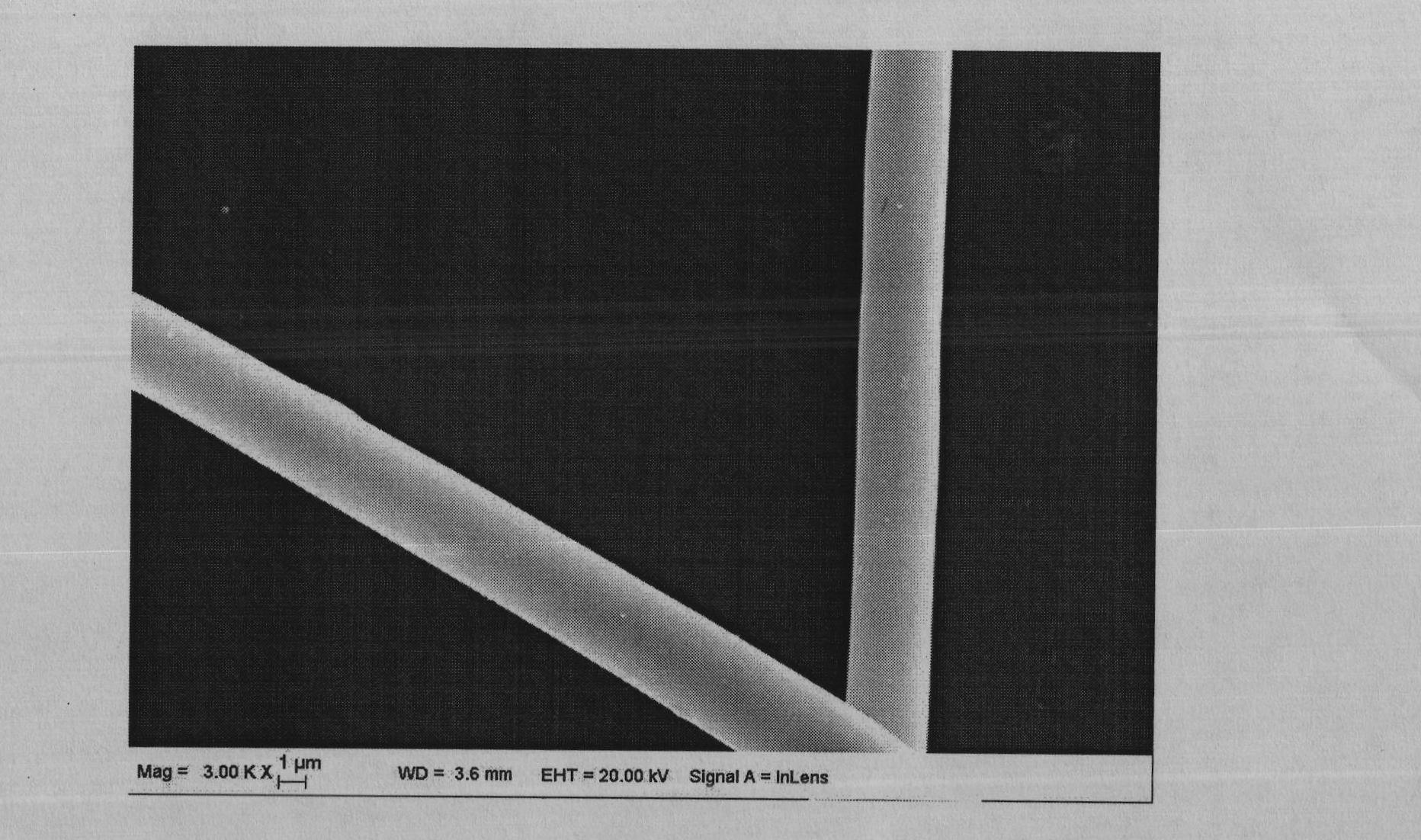

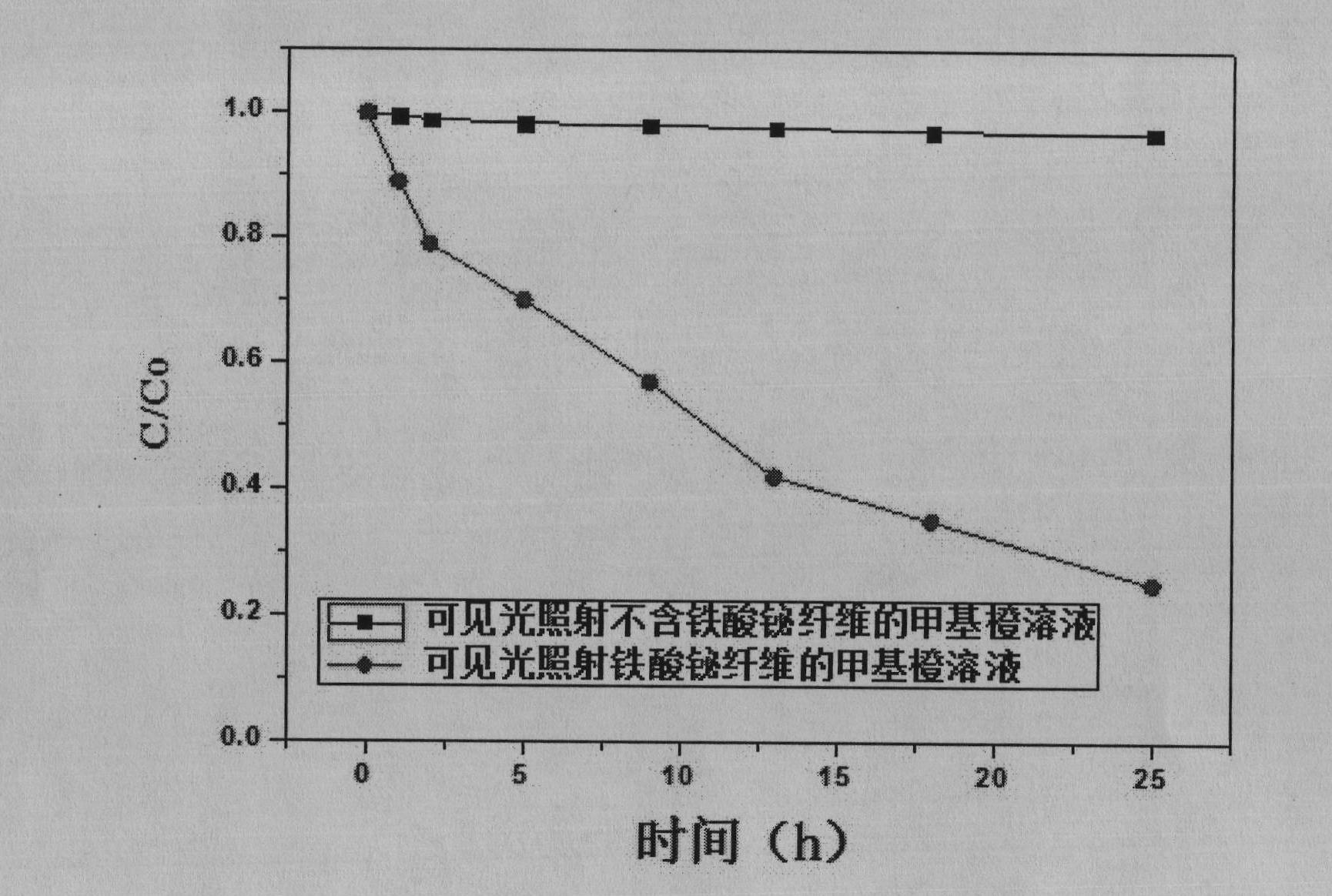

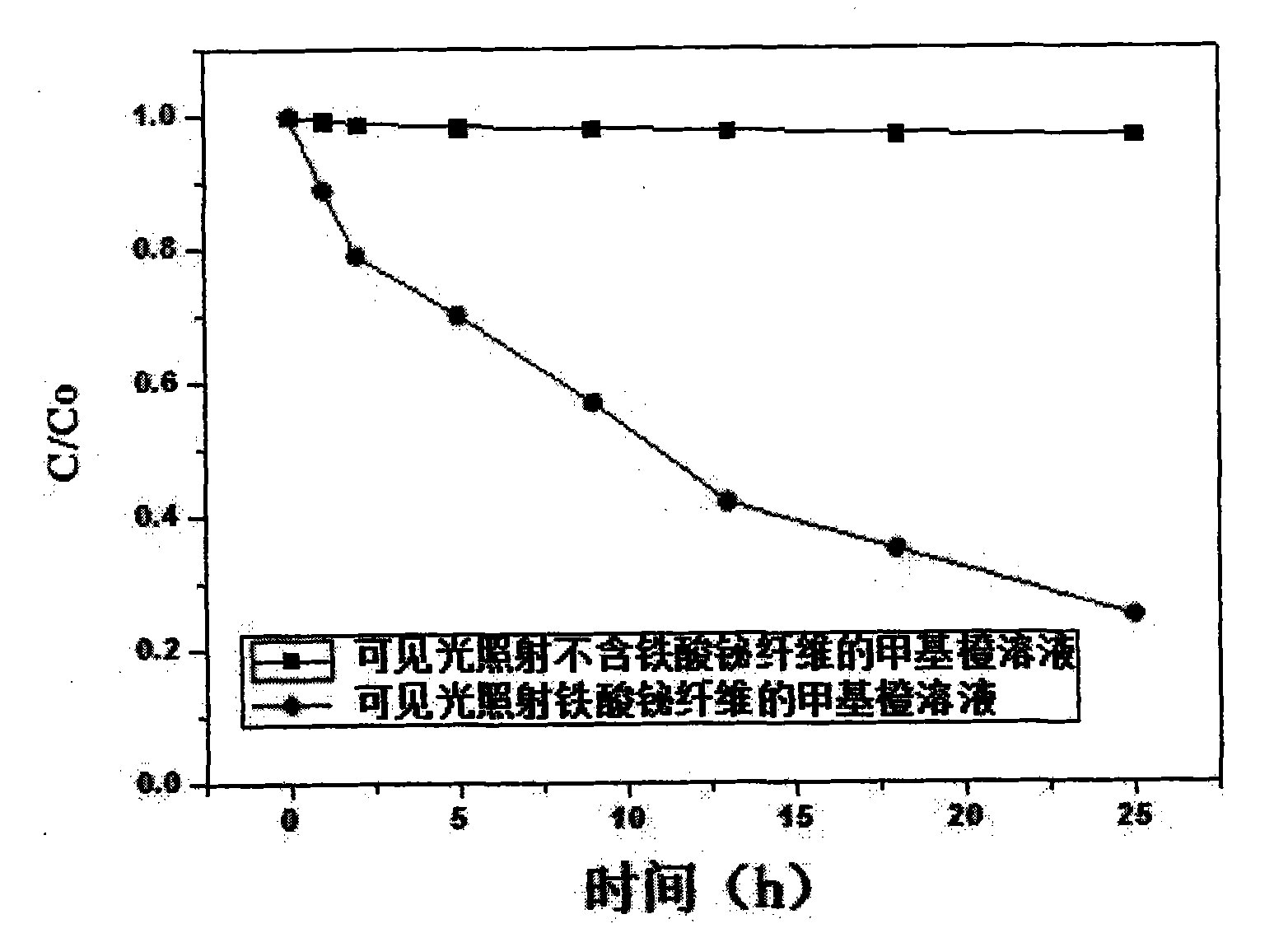

[0015] Example 1, first dissolving citric acid into deionized water to form a citric acid solution with a concentration of 0.2g / mL; then adding iron nitrate and bismuth nitrate to the citric acid solution and stirring until clear and transparent, wherein The molar ratio of the acid is 2:1:6; after the solution is allowed to stand for 48 hours, it is placed in a water bath and heated and stirred at 60°C for 4 hours, and the solution is added with a molecular weight of 1.3×10 6 Continue to stir until the polyvinylpyrrolidone is completely dissolved, so that the concentration of polyvinylpyrrolidone is kept at 0.03g / mL; finally, add this polymer solution to a plastic syringe with an inner diameter of 2mm and a stainless steel needle. Add the syringe to the syringe pump, start the syringe pump to make the injection flow rate 0.3mL / h, and turn on the high-voltage power supply to provide a voltage of 20kV to the needle, and collect the fibers with a single crystal silicon wafer; plac...

Embodiment 2

[0017] Example 2, first dissolving citric acid into deionized water to form a citric acid solution with a concentration of 0.4g / mL; then adding ferric nitrate and bismuth nitrate to the citric acid solution and stirring until clear and transparent, wherein ferric nitrate, bismuth nitrate, lemon The molar ratio of the acid is 2:1:6; after the solution is allowed to stand for 24 hours, it is placed in a water bath and heated and stirred at 50°C for 7 hours, and the solution is added with a molecular weight of 1.3×10 6 Continue to stir until the polyvinylpyrrolidone is completely dissolved, so that the concentration of polyvinylpyrrolidone is kept at 0.02g / mL; finally, add this polymer solution to a plastic syringe with an inner diameter of 1mm and a stainless steel needle. Add the syringe to the syringe pump, start the syringe pump to make the injection flow rate 0.7mL / h, and turn on the high-voltage power supply to provide a voltage of 25kV to the needle, and collect the fibers ...

Embodiment 3

[0019] Example 3, first dissolving citric acid into deionized water to form a citric acid solution with a concentration of 0.3g / mL; then adding ferric nitrate and bismuth nitrate to the citric acid solution and stirring until clear and transparent, wherein ferric nitrate, bismuth nitrate, lemon The molar ratio of the acid is 2:1:6; after the solution is allowed to stand for 72 hours, it is placed in a water bath and heated and stirred at 70°C for 6 hours, and the solution is added with a molecular weight of 1.3×10 6 Continue to stir until the polyvinylpyrrolidone is completely dissolved, so that the concentration of polyvinylpyrrolidone is kept at 0.04g / mL; finally, add this high polymer solution to a plastic syringe with an inner diameter of 3mm and a stainless steel needle. Add the syringe to the syringe pump, start the syringe pump to make the injection flow rate 0.4mL / h, and turn on the high-voltage power supply to provide a voltage of 30kV to the needle, and collect the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com