Preparation and application method for composite phosphorus removing agent for treating high-concentration phosphorus-containing waste water

A compound dephosphorization agent, high-concentration technology, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of not being able to be used as a dephosphorization agent, and achieve low production cost and simple reaction conditions , The effect of simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

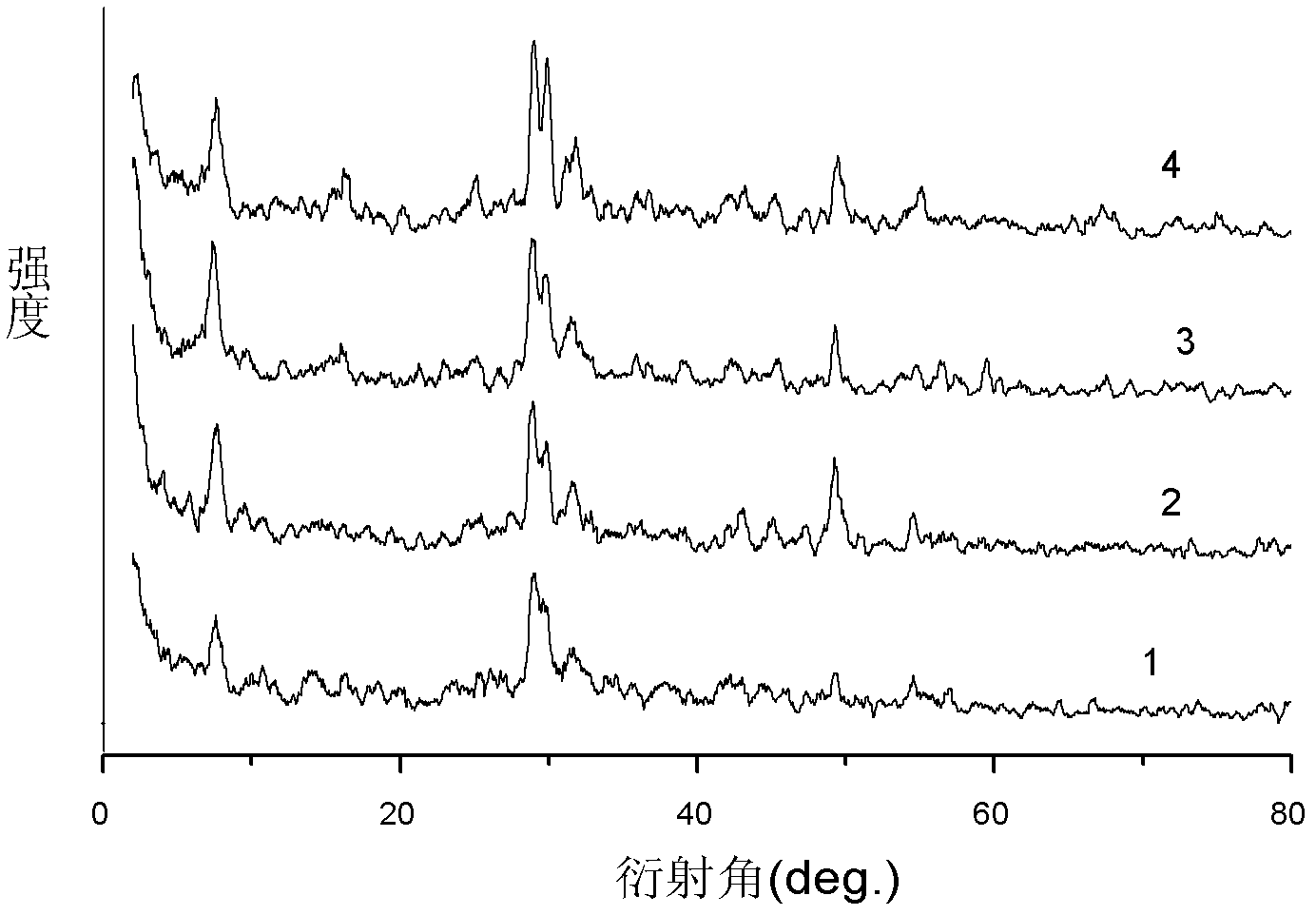

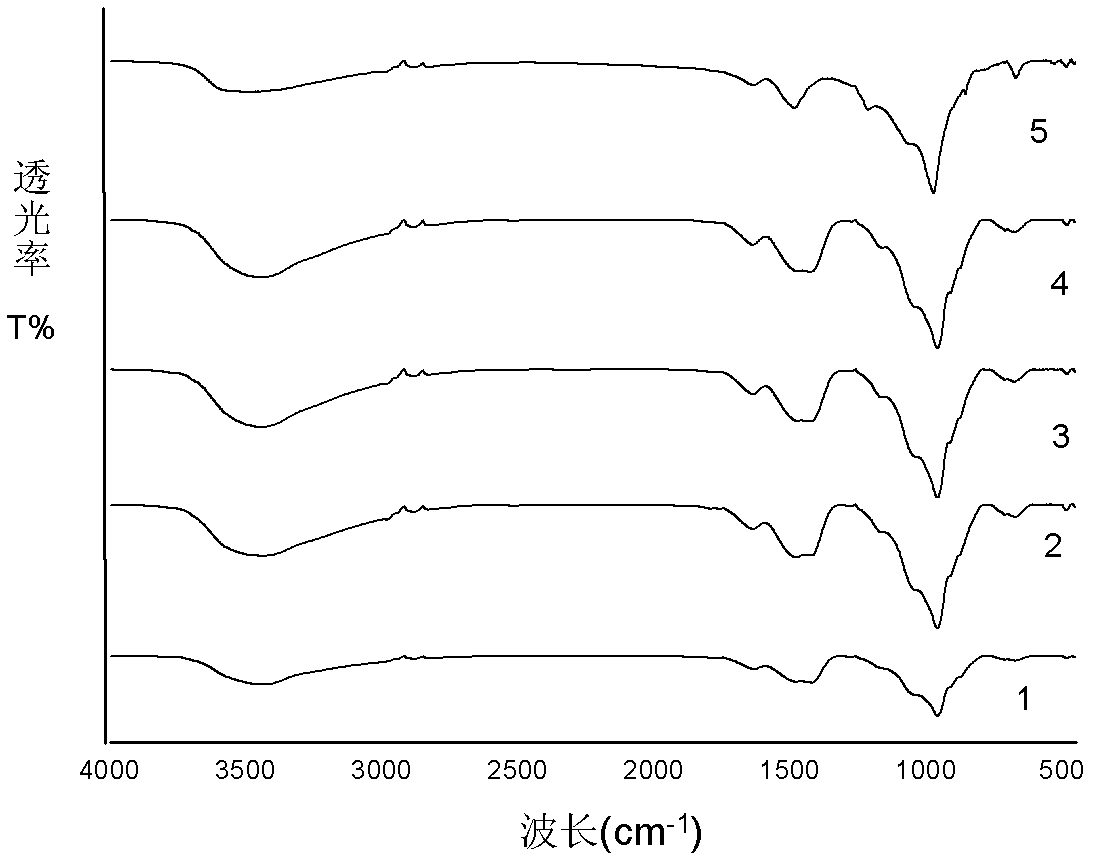

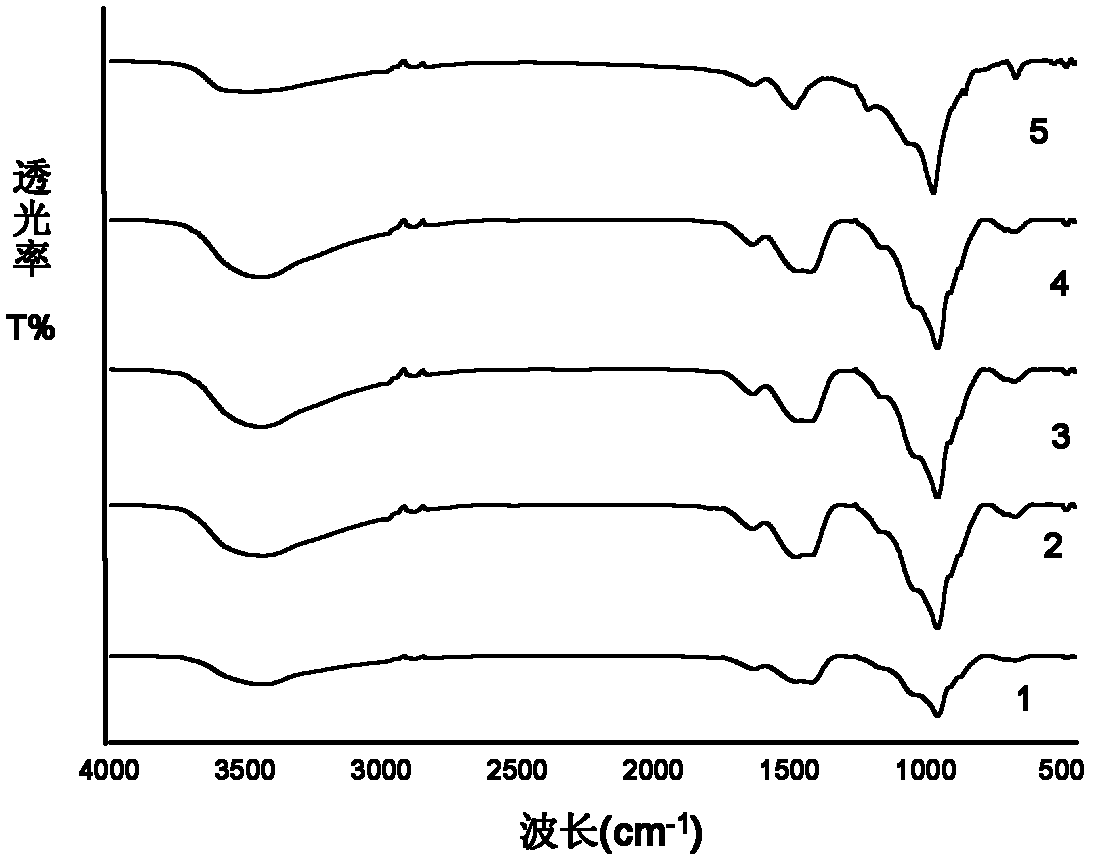

Method used

Image

Examples

Embodiment 1

[0021] a) Take 0.912g of zeolite, 2.83g of sodium silicate, 1.536g of calcium oxide, 25.0g of water, fully stir it and place it in a 50mL reactor at a heating rate of 5°C / min, and raise it to 180°C for reaction. The reaction time is 10h. Cooling, filtering to obtain white solid material, solid material is washed, dried to obtain composite phosphorus removal agent.

[0022] b) Use the composite phosphorus removal agent prepared above to treat simulated high-concentration phosphorus-containing wastewater, with a phosphorus concentration of 100mg / L, add 4.0g of the composite phosphorus removal agent prepared above to each liter of phosphorus-containing wastewater, stir for 1 hour, and effluent The phosphorus content in wastewater is 0.2319mg / L. The removal rate of phosphorus is ≥99.77%.

Embodiment 2

[0024] a) Take 0.912g of zeolite, 2.83g of sodium silicate, 1.400g of calcium oxide, 25.0g of water, fully stir and place it in a 50mL reactor at a heating rate of 5°C / min, and raise the temperature to 180°C for reaction. The reaction time is 10h. Cooling, filtering to obtain white solid material, solid material is washed, dried to obtain composite phosphorus removal agent.

[0025] b) Use the composite phosphorus removal agent prepared above to treat simulated high-concentration phosphorus-containing wastewater, with a phosphorus concentration of 50mg / L, add 4.0g of the composite phosphorus removal agent prepared above to each liter of phosphorus-containing wastewater, stir for 1 hour, and effluent The phosphorus content in wastewater is 0.3338mg / L. The removal rate of phosphorus is ≥99.33%.

Embodiment 3

[0027] a) Take 1.00g of zeolite, 2.50g of sodium silicate, 1.600g of calcium oxide, 30.0g of water, fully stir and place it in a 50mL reactor at a heating rate of 5°C / min, and raise the temperature to 180°C for reaction. The reaction time is 8h. Cooling, filtering to obtain white solid material, solid material is washed, dried to obtain composite phosphorus removal agent.

[0028] b) Use the composite phosphorus removal agent prepared above to treat simulated high-concentration phosphorus-containing wastewater, with a phosphorus concentration of 20mg / L, add 4.0g of the composite phosphorus removal agent prepared above to each liter of phosphorus-containing wastewater, stir for 1h, and effluent The phosphorus content in wastewater is 0.3433mg / L. The removal rate of phosphorus is ≥98.28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com