Composite microorganism preparation and application thereof in waste water treatment

A technology for compound microorganisms and wastewater treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , the effect of efficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015]The present embodiment is carried out as follows:

[0016] The waste water is a leather waste water in Zhejiang Province. After physical and chemical treatment, the waste water directly enters the biological treatment system. The water quality indicators entering the biological treatment system are as follows:

[0017] COD: 2000--2500 mg / l

[0018] NH 4 + -N: 250 mg / l

[0019] PH value: 8.0—9.5

[0020] Project water volume is 3000 m 3 / d, A (facultative oxygen) / O (aerobic) process, the operating process conditions are as follows:

[0021] Residence time: 48h, facultative 12h, aerobic 36h

[0022] Temperature: 25-35°C

[0023] Aerobic DO: 2~5mg / l

[0024] Put into the biochemical pool the compound microbial preparation whose initial concentration is 1.5‰ (volume ratio) of the treatment volume of the biochemical pool.

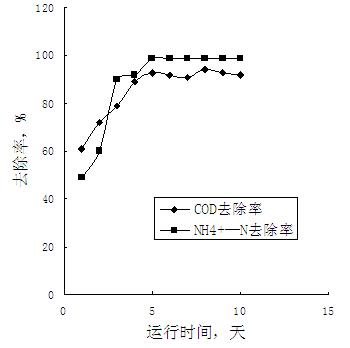

[0025] After one-time dosing, after 5-10 days of stable operation, the removal rate of COD in leather wastewater is maintained at about 92.5%, th...

Embodiment 2

[0027] The present embodiment is carried out as follows:

[0028] The wastewater is wastewater containing high concentration of organic nitrogen from a methylamine enterprise in Zhejiang. After being treated by air flotation and degreasing, the wastewater directly enters the biological treatment system. The water quality indicators entering the biological treatment system are as follows:

[0029] COD: 1000--2000 mg / l

[0030] NH 4 + -N: 300--400 mg / l

[0031] TN: 500--800 mg / l

[0032] PH value: 8.5—9.0

[0033] Project water volume is 1000 m 3 / d, A (facultative oxygen) / O (aerobic) process, the operating process conditions are as follows:

[0034] Residence time: 36h, facultative 24h, aerobic 48h

[0035] Temperature: 25-35°C

[0036] Aerobic DO: 2~5mg / l

[0037] Put into the biochemical pool the compound microbial preparation whose initial concentration is 2.0‰ (volume ratio) of the treatment volume of the biochemical pool.

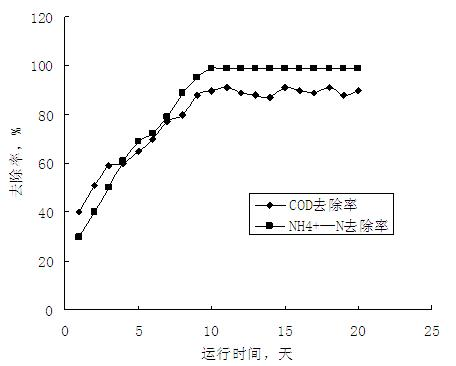

[0038] After one-time dosing, after 10-...

Embodiment 3

[0040] The present embodiment is carried out as follows:

[0041] The wastewater is coking wastewater from a coking plant in Shandong. After being treated by air flotation and degreasing, the wastewater directly enters the biological treatment system. The water quality indicators entering the biological treatment system are as follows:

[0042] COD: 3000--5000 mg / l

[0043] NH 4 + -N: 200--400 mg / l

[0044] PH value: 7.5---9.0

[0045] The project water volume is 2300 m 3 / d, A (anaerobic) / A (facultative oxygen) / O (aerobic) process, the operating process conditions are as follows:

[0046] Residence time: 76h, anaerobic 8h, facultative oxygen 20h, aerobic 48h

[0047] Temperature: 25-35°C

[0048] DO: 2~5mg / l

[0049] Put into the biochemical pool the compound microbial preparation whose initial concentration is 2.5‰ (volume ratio) of the treatment volume of the biochemical pool.

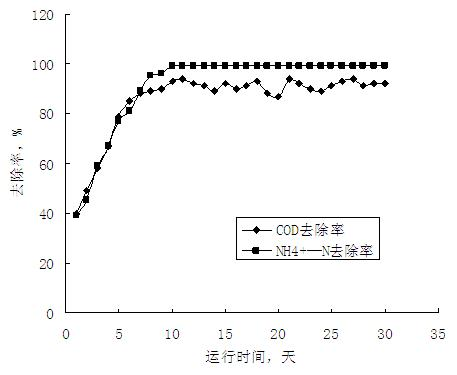

[0050] After one-time dosing, after 30-60 days of stable operation, the removal rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com