Glutamic acid synergist urea and preparation method thereof

A technology of glutamic acid and urea, applied in the direction of fertilizer mixture, fertilization device, application, etc., to reduce nutrient loss, avoid secondary pollution, and simplify agricultural operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

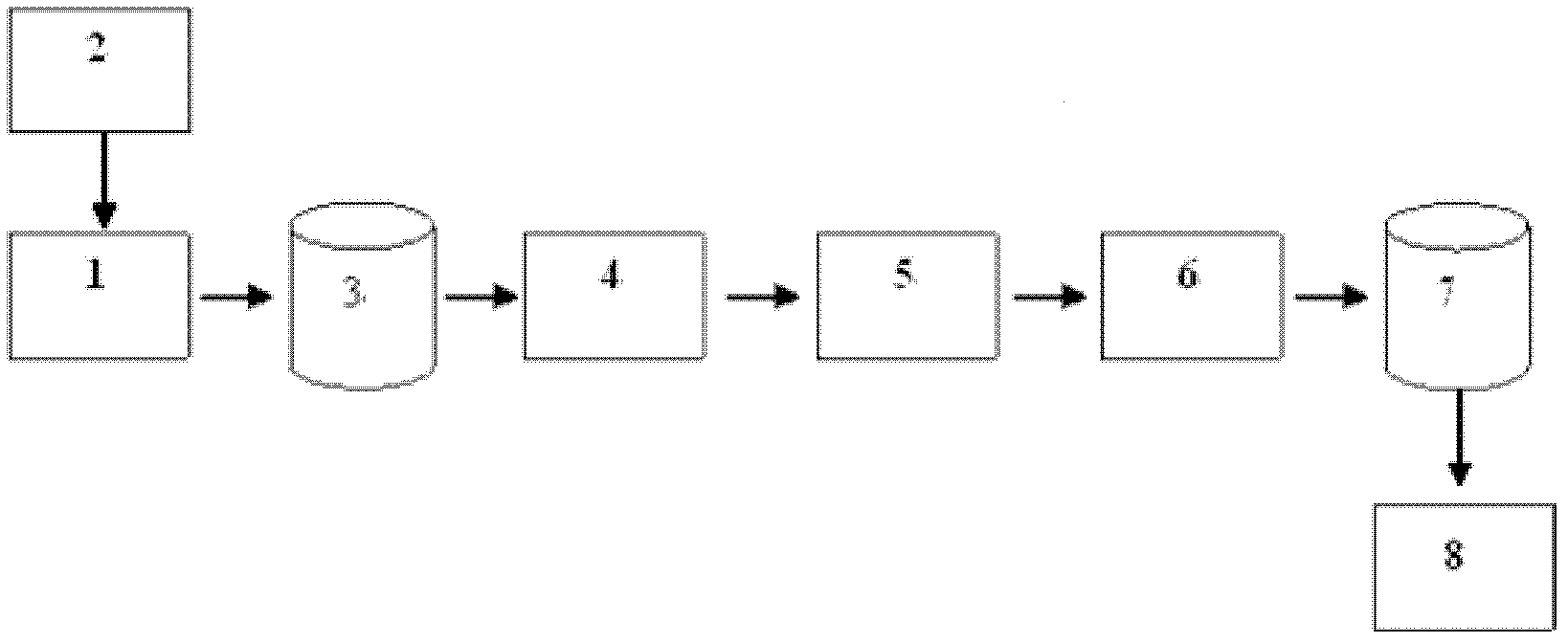

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Preparation of glutamic acid synergistic urea of the present invention

[0051] The steps are as follows:

[0052] Step 1, preparation of glutamic acid synergist

[0053] Prepare a sodium glutamate solution with a concentration of 25% by weight to obtain the glutamate synergist A;

[0054] Step 2, preparation of glutamic acid synergistic urea

[0055] Between the first stage evaporation and the second stage evaporation of the conventional urea prilling tower, use the urea evaporator sold by Yantai Yamei Special Metal Co., Ltd., and use the metering pump to pump 100kg of glutamic acid synergist into 10 tons of urea melt , to obtain a glutamic acid synergistic urea melt;

[0056] Step 3. High tower cooling granulation

[0057] The glutamic acid synergistic urea molten liquid obtained in step 2 is pumped into the tower top reaction tank through the urea melting pump sold by Xi'an Pump Valve Manufacturing Co., Ltd., sprayed out through the rotating nozzl...

Embodiment 2

[0060] Embodiment 2: Preparation of glutamic acid synergistic urea of the present invention

[0061] This embodiment is carried out in the same manner as in Example 1, except that a sodium glutamate solution with a concentration of 15% by weight is used as the glutamic acid synergist A; 300 kg of glutamic acid synergist and 10 tons of urea melt are used.

[0062] According to the analysis method described in this specification, the nitrogen content of the glutamic acid-enhanced urea obtained in this example is 46.0% based on the total weight of the glutamic acid-enhanced urea.

Embodiment 3

[0063] Embodiment 3: Preparation of glutamic acid synergistic urea of the present invention

[0064] This embodiment is carried out in the same manner as Example 1, just use concentration 12% by weight sodium hydroxide solution and glutamic acid to mix by the ratio of 2.3: 1 (weight ratio), obtain glutamic acid synergist B; 400kg of glutamic acid synergist and 10 tons of urea melt.

[0065] Using the analysis method described in this specification, the nitrogen content of the glutamic acid-enhanced urea obtained in this example is 45.9% based on the total weight of the glutamic acid-enhanced urea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com