Separation method for mixture of triethylene-diamine and ethanolamine

A technology of triethylenediamine and separation method, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., to achieve the effect of simple separation operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

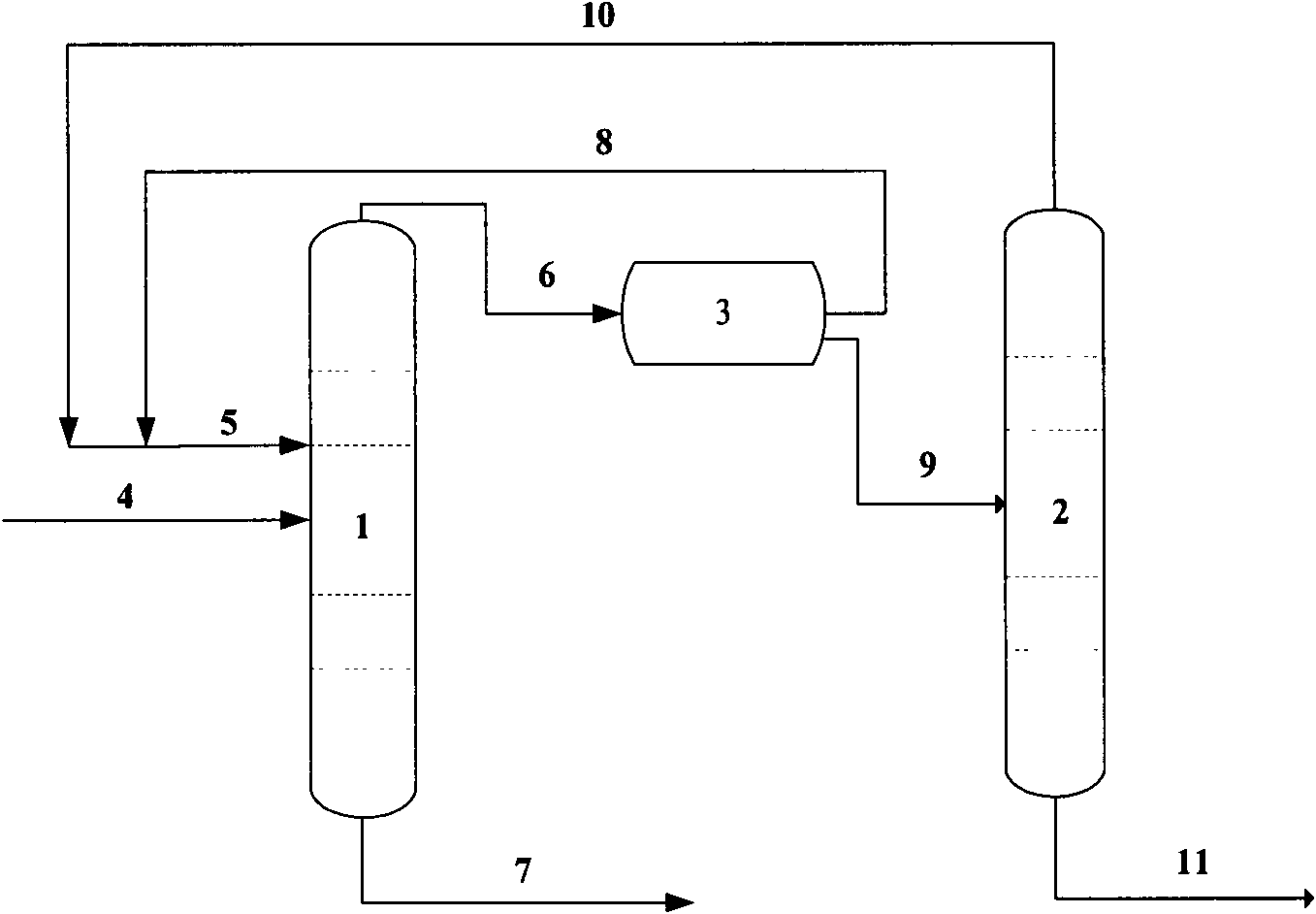

Method used

Image

Examples

Embodiment 1

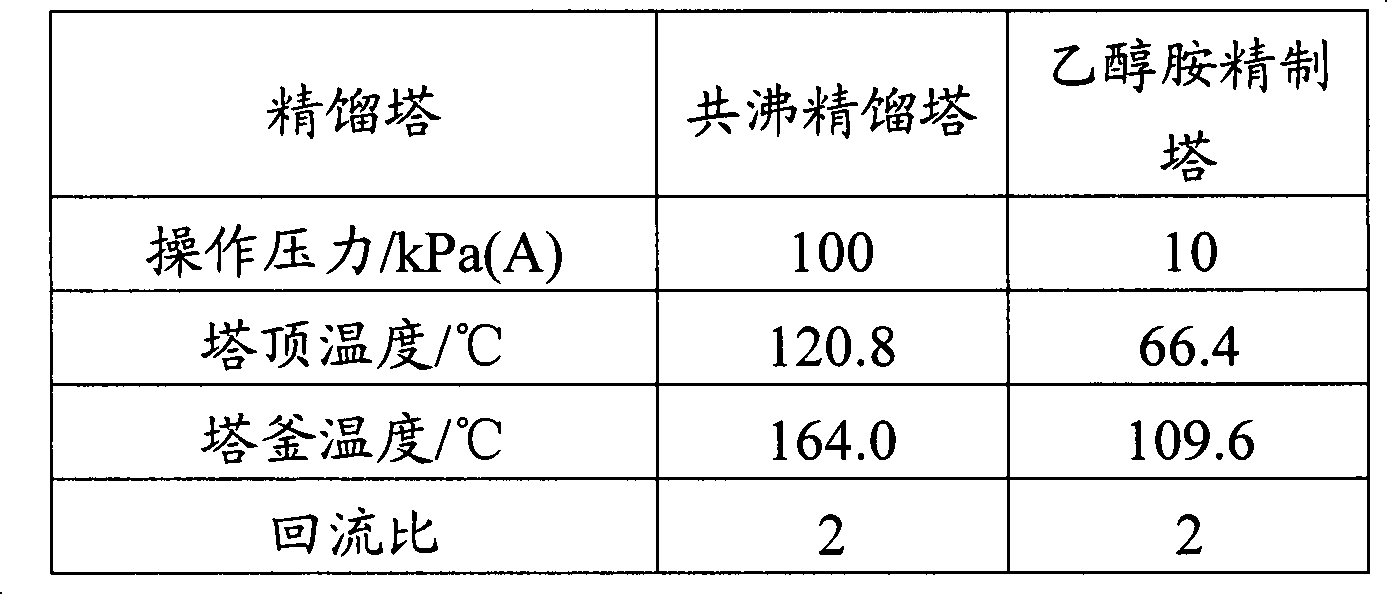

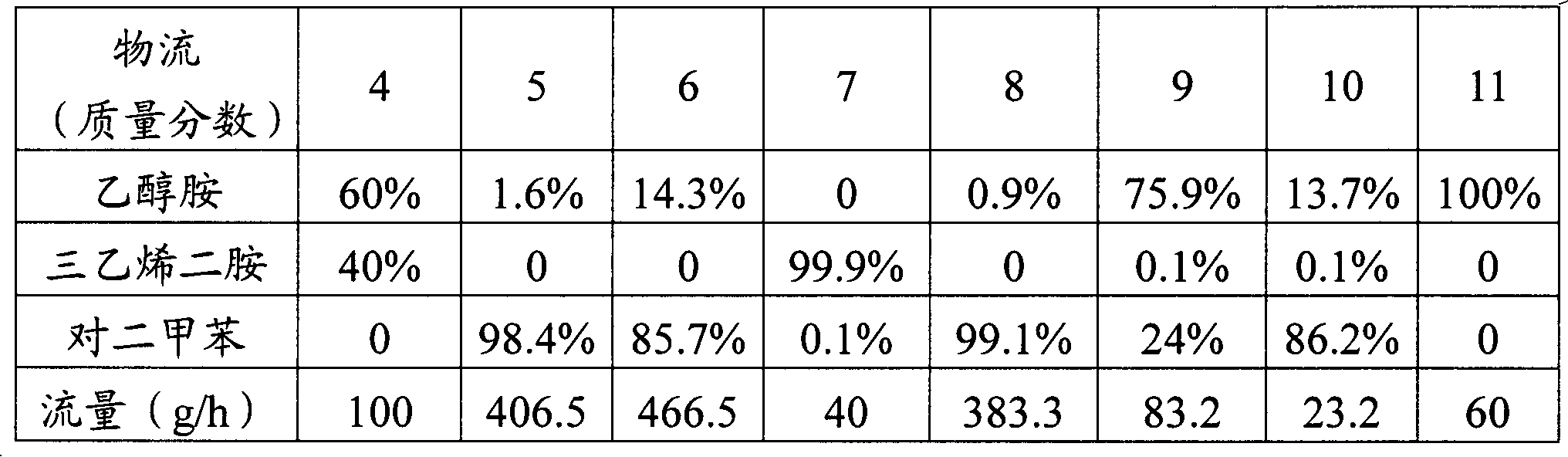

[0020] The feed material containing triethylenediamine and ethanolamine and the entrainer recycle stream are fed from the middle of the azeotropic rectification tower. The azeotropic rectification tower is a packed tower with a diameter of Φ25mm and a built-in Φ3*3θ ring stainless steel filler. The packing layer Height 0.8m. The top of the azeotropic distillation column is the azeotrope of the entrainer and ethanolamine, which enters the phase separator, and the distillate in the bottom of the tower is triethylenediamine product; the operating pressure of the phase separator is 100kPa, and the operating temperature is 30°C. The upper layer is the p-xylene phase, which is recycled to the middle of the azeotropic distillation column for feeding, and the lower layer is the crude product of ethanolamine, which enters the ethanolamine refining tower; the lower layer of the phase separator is fed from the middle of the ethanolamine refining tower, which is a packed tower , the tower...

Embodiment 2

[0028] The operation process of Example 2 is similar to that of Example 1, except that the operating parameters of the azeotropic distillation column and the ethanolamine refining column are different. The operating parameters are shown in Table 3, and the stream composition of Example 2 is shown in Table 4.

[0029] Tower operation parameter in the embodiment 2 of table 3

[0030]

[0031] The logistics composition in the embodiment 2 of table 4

[0032]

Embodiment 3

[0034] The operation process of Example 3 is similar to that of Example 1, except that the mass ratio of entrainer to ethanolamine is 15:1, and the stream composition of Example 3 is shown in Table 5.

[0035] The logistics composition in the embodiment 3 of table 5

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com